Treatment method for adjusting color difference of wood veneer

A technology of wood veneer and treatment method, which is applied in the direction of wood treatment, wood treatment details, wood impregnation, etc., can solve the problems of deepening the color of wood veneer, veneer color difference, large surface corrosion, high processing cost, etc. The effect of chromatic aberration, improving whiteness, and mitigating corrosion conditions

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

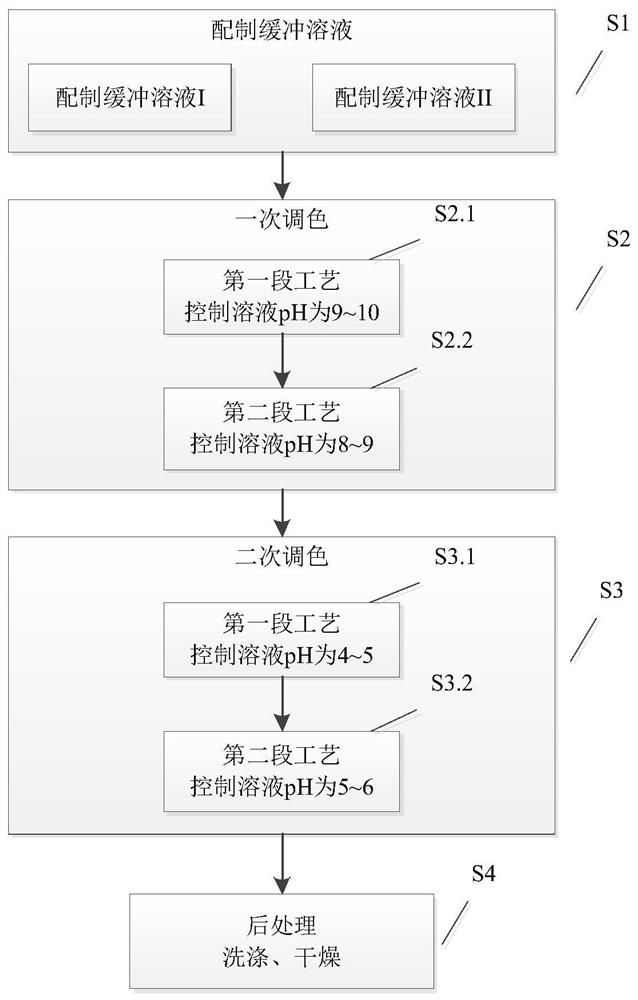

[0039] Wood has a natural tone, and lignin is one of the main reasons why wood has different colors. There are chromophoric groups (such as carbonyl, carboxyl and alkene conjugated to benzene ring) and auxochromic groups (such as phenolic hydroxyl and alcoholic hydroxyl) in the lignin structure. In this embodiment, for the condition of darker wood color, the secondary toning method is adopted. Specifically, poplar veneer is selected as the experimental object for processing, including a total of 4 veneers, which are respectively marked as A, B, C, and D. The specific process flow diagram is attached figure 1 shown.

[0040] S1: configure buffer solution;

[0041] Sodium carbonate and sodium bicarbonate are added to water to obtain a buffer solution I, wherein the mass fraction of the sodium carbonate is 2 to 5%, and the mass fraction of the sodium bicarbonate is 1 to 5%;

[0042] adding glacial acetic acid and sodium acetate to water to obtain buffer solution II, wherein th...

Embodiment 2

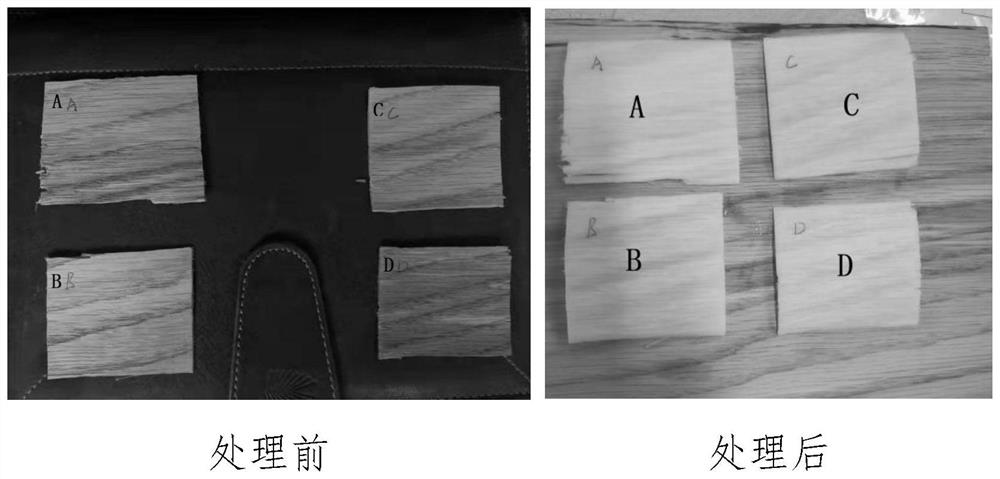

[0058] In this embodiment, the poplar veneer is treated, including 4 veneers, which are respectively marked as A, B, C, and D. The specific method is as follows. figure 2 shown.

[0059] S1: prepare buffer solution;

[0060] adding glacial acetic acid and sodium acetate into water to obtain a buffer solution, wherein the mass fraction of the glacial acetic acid is 5-10%, and the mass fraction of the sodium acetate is 2-5%;

[0061] S2: toning;

[0062] The first stage: take the buffer solution, place the wood veneer in the buffer solution, add the toner, heat to 60-80°C, control the pH value of the solution to 4, and treat for 60 minutes;

[0063] The second stage: adjust the pH value of the solution to 6, and treat for 60 minutes.

[0064] S3: post-processing;

[0065] Take out the wood veneer after toning, wash it in water, and dry it for use;

[0066] Wherein, the toner is a sodium chlorite solution with a mass fraction of 2.0%, and the mass ratio of the buffer soluti...

Embodiment 3

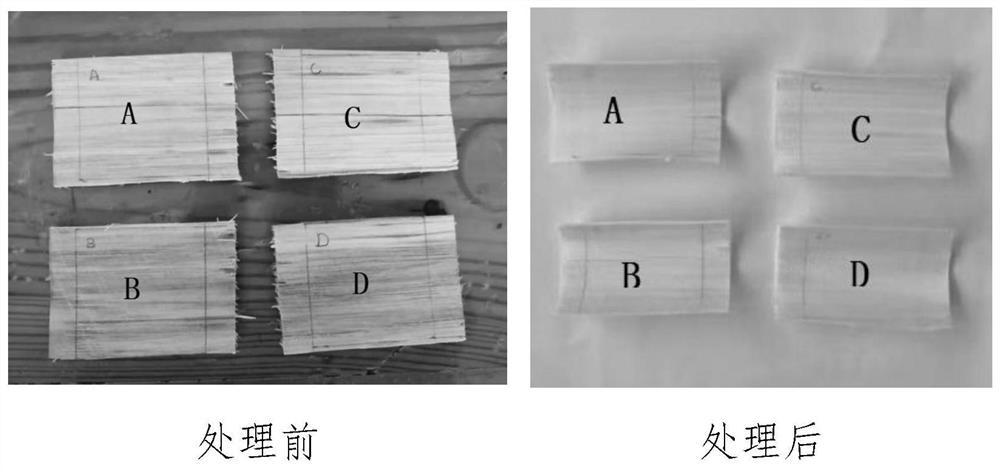

[0069] In this embodiment, bamboo and wood veneers are treated, including 4 veneers, which are respectively marked as A, B, C, and D. The specific method is the same as in Example 2. The whiteness comparison diagram of bamboo and wood veneers before and after treatment is as attached image 3 Shown below.

PUM

| Property | Measurement | Unit |

|---|---|---|

| quality score | aaaaa | aaaaa |

| quality score | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com