Magnesium alloy conversion coating enhancement treatment agent and magnesium alloy surface treatment method

A technology of enhanced treatment and surface treatment, which is applied in the direction of metal material coating process, etc., can solve the problems of being easily scratched and damaged, and the surface of magnesium alloy is corroded and oxidized, so as to improve the hardness and scratch resistance effect, and improve the corrosion resistance effect , enhance the effect of various performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

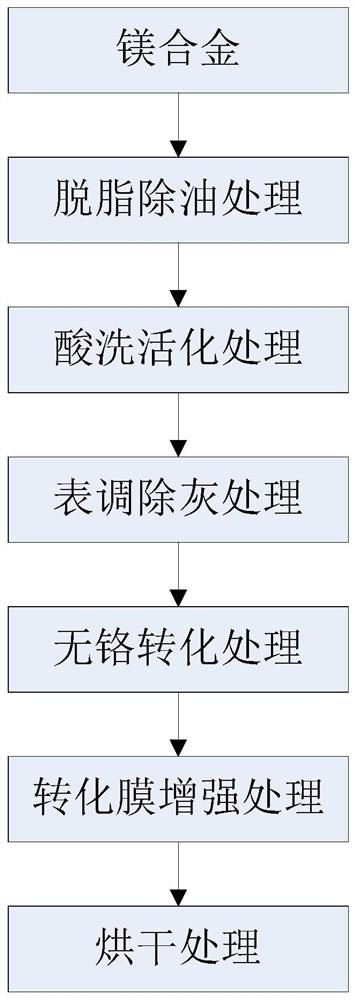

Method used

Image

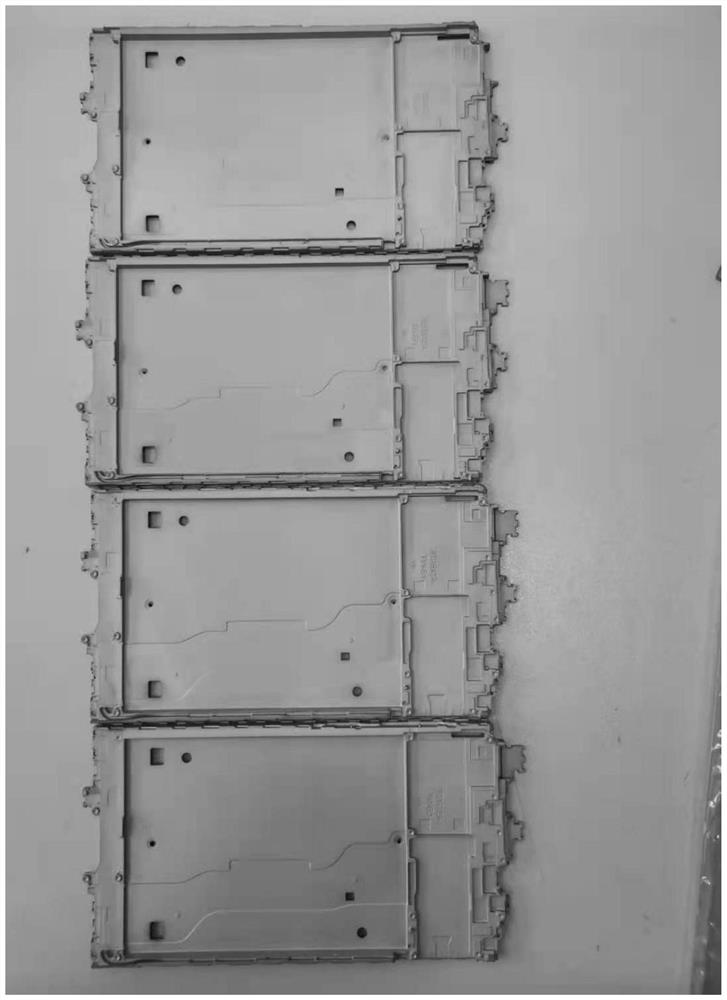

Examples

Embodiment 1

[0032] Degreasing and degreasing treatment: Immerse the magnesium alloy workpiece in the degreasing agent, treat it at 60 °C for 6 minutes, and then enter the pickling activation treatment operation after washing with water. The degreasing agent includes the following components: sodium hydroxide 10 g / L, HEDP 20 g / L, sodium pyrophosphate 5 g / L, 1309 iso-alcohol ether 1.25 g / L, alkyl glycoside 1 g / L, and the balance is water.

[0033] Pickling Activation Treatment: Immerse the degreasing and degreasing magnesium alloy workpiece in M330 pickling agent (produced by Dongming Chemical Industry, Boluo County), the usage amount is 8-10% for slotting, under the condition of 50-60 ℃, treat 1 -2min, after washing with water, enter the table adjustment ash removal operation.

[0034] Surface adjustment and ash removal treatment: Immerse the magnesium alloy workpiece after pickling and activation treatment in M440 surface adjustment agent (produced by Dongming Chemical Industry, Boluo Co...

Embodiment 2

[0040] The difference from Example 1 is that the magnesium alloy conversion coating enhancement treatment agent of Example 2 includes the following components: myristic acid 3 g / L, oleic acid 5 g / L, TX-10 emulsifier 5 g / L, no Water ethanol 15 g / L, monoethanolamine 5 g / L, and the balance is water.

Embodiment 3

[0042] The difference from Example 1 is that the magnesium alloy conversion coating enhancement treatment agent of Example 3 includes the following components: lauric acid 3 g / L, myristic acid 3 g / L, oleic acid 3 g / L, TX-10 emulsification 5 g / L of agent, 15 g / L of anhydrous ethanol, 5 g / L of monoethanolamine, and the balance is water.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com