PVT method high-quality single crystal growth thermal field device and method

A high-quality, single-crystal technology, applied in the direction of single crystal growth, single crystal growth, crystal growth, etc., can solve problems such as poor single crystal quality and seed crystal damage, achieve good crystal quality, reduce the generation of impurities in the crystal, The effect of improving quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

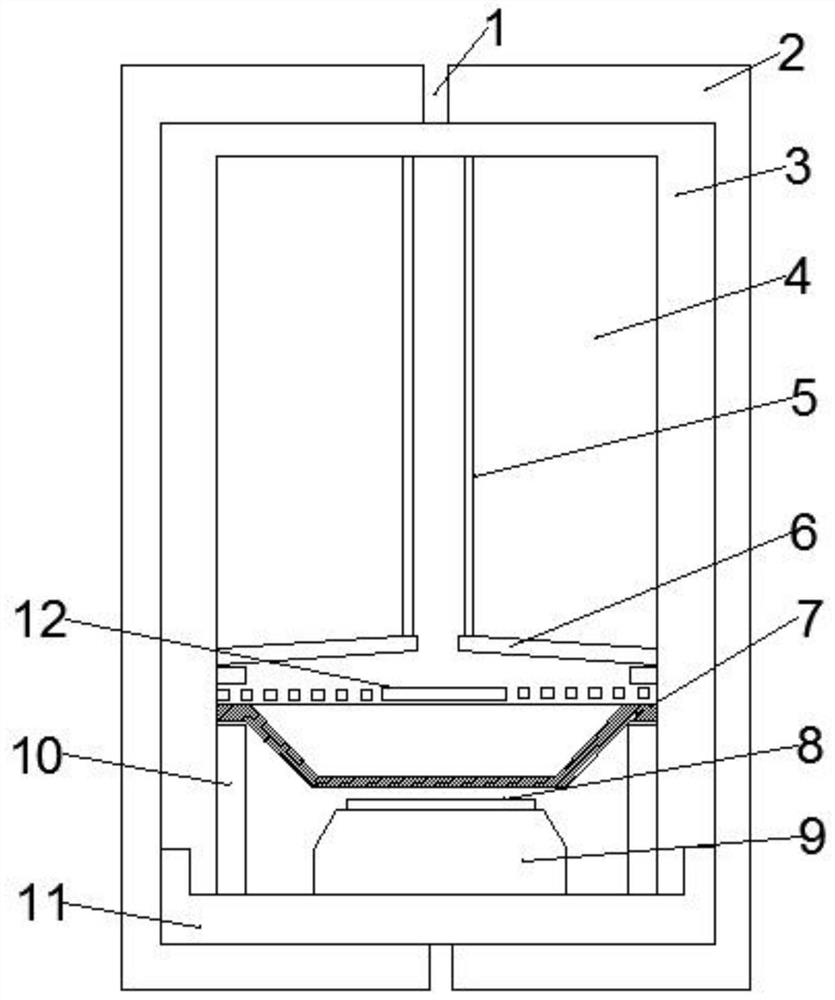

[0028] Specific implementation mode one: combine figure 1 Describe this embodiment, a PVT method high-quality bulk single crystal growth thermal field device in this embodiment, including graphite insulation material 2, crucible body 3, graphite cylinder 5, support structure 6, guide cylinder 7, seed crystal support 9 , support graphite cylinder 10, crucible cover 11 and disc 12, crucible body 3 is inverted, graphite cylinder 5 is installed in the crucible body 3 through support structure 6, crucible body 3 side walls, crucible body 3 bottom surfaces, graphite cylinder 5 outer walls and support The raw material placement area 4 is formed between the structures 6, and the raw materials are filled into the raw material placement area 4; the disc 12 is fixedly installed on the inner wall of the crucible body 3, and is located under the supporting structure 6, and the guide tube 7 is installed sequentially under the disc 12 And supporting graphite cylinder 10, crucible cover 11 is...

specific Embodiment approach 2

[0029] Specific implementation mode two: combination figure 1 Describe this embodiment, a PVT method high-quality bulk single crystal growth thermal field device of this embodiment, the upper end and the lower end of the graphite insulation material 2 are respectively provided with a temperature measurement window 1, which can be measured by measuring the temperature window 1 during the crystal preparation process The temperature window 1 measures the temperature of the upper and lower ends of the crucible in real time to prevent the crystal growth quality from being too high or too low.

specific Embodiment approach 3

[0030] Specific implementation mode three: combination figure 1 Describe this embodiment, a kind of PVT method high-quality single crystal growth thermal field device of this embodiment, described graphite tube 5 is loose porous structure, and the pore diameter of loose porous structure is smaller than the diameter of raw material particle, and the outer diameter of graphite tube 5 In the range of 30-150mm, the diameter of the graphite cylinder 5 surface is smaller than the particle diameter of the raw material to prevent the raw material from leaking from the graphite cylinder 5 before forming the gas phase. The graphite cylinder 5 can change the outer diameter correspondingly according to the thickness of the prepared crystal and the amount of raw material the size of.

[0031] Specific implementation mode four: combination figure 1 Describe this embodiment, a PVT method high-quality bulk single crystal growth thermal field device in this embodiment, the wall thickness of t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com