A kind of thickener suspoemulsion for fracturing fluid and preparation method thereof

A technology of suspending emulsion and thickener, which is applied in the direction of chemical instruments and methods, drilling compositions, etc., can solve the problems of continuous mixing and large displacement construction, low solid content of polyacrylamide, and easy occurrence of "fish eyes". " and other problems, to achieve the effect of improving the suspension performance, shortening the dissolution time, and improving the dissolution performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

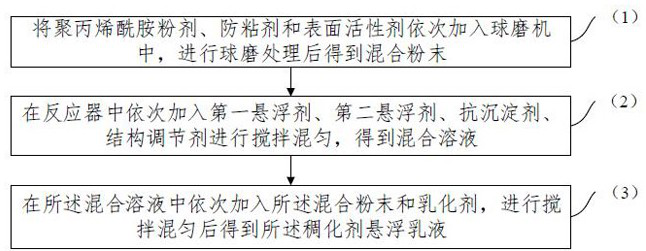

[0033] Such as figure 1 As shown, the invention provides a kind of preparation method of thickener suspoemulsion for fracturing fluid, and this preparation method comprises the steps:

[0034] (1) Add polyacrylamide powder, anti-adhesive agent and surfactant to the ball mill in sequence, and obtain mixed powder after ball milling;

[0035] (2) Add the first suspending agent, the second suspending agent, the anti-sedimentation agent, and the structure regulator into the reactor in sequence and stir to obtain a mixed solution;

[0036] (3) Add the mixed powder and emulsifier in sequence to the mixed solution and stir to obtain the thickener suspoemulsion.

[0037] It should be noted that the above steps (1) to (2) are all carried out at normal temperature (usually 25° C.), that is, without heating.

[0038] The solid content of polyacrylamide in the thickener suspoemulsion obtained by the present invention is higher, reaching 55%-60%. The time is shorter, so the amount of thi...

Embodiment 1

[0085] (1) Add 55 parts of polyacrylamide powder (particle size ≤ 125 μm) and 1 part of anti-sticking agent (calcium stearate, particle size ≤ 125 μm) into the tubular ball mill, turn on the ball mill for 30 minutes, and then add Surfactant 0.6 parts (sodium dodecylsulfonate), and continue ball milling for 30 minutes to obtain mixed powder;

[0086] (2) Add 35 parts of the first suspending agent (No. 5 white oil) and 8 parts of the second suspending agent (amyl alcohol) into the reactor (reactor), turn on the mixer of the reactor, stir at 50Hz for 30min to disperse and mix Finally, add 2 parts of anti-precipitation agent (organic bentonite), continue to stir at 50 Hz for 30 minutes to disperse and mix, then add 0.6 parts of structure regulator (diethylene glycol ether), and continue to stir at 50 Hz for 30 minutes to disperse and mix. to obtain a mixed solution;

[0087] (3) Add the mixed powder obtained in step (1) to the mixed solution in step (2), stir at 50 Hz for 60 minu...

Embodiment 2

[0089] (1) Add 58 parts of polyacrylamide powder (particle size ≤ 125 μm) and 1.2 parts of anti-sticking agent (magnesium stearate, particle size ≤ 125 μm) into the tubular ball mill, turn on the ball mill for 30 minutes, and then add Surfactant 0.8 part (sodium lauryl sulfate), and continue ball milling treatment for 30min to obtain mixed powder;

[0090] (2) Add 33 parts of the first suspending agent (No. 3 white oil) and 10 parts of the second suspending agent (hexanol) into the reactor (reactor), turn on the mixer of the reactor, stir at 50 Hz for 30 minutes to disperse and mix Finally, add 1.5 parts of anti-precipitation agent (polyamide modified hydrogenated castor oil), continue stirring at 50 Hz for 30 minutes to disperse and mix, then add 0.8 parts of structure regulator (diethylene glycol butyl ether), continue to stir at 50 Hz Stir for 30 minutes to disperse and mix to obtain a mixed solution;

[0091] (3) Add the mixed powder obtained in step (1) to the mixed solu...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| solid content | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com