System for treating and recycling composite material

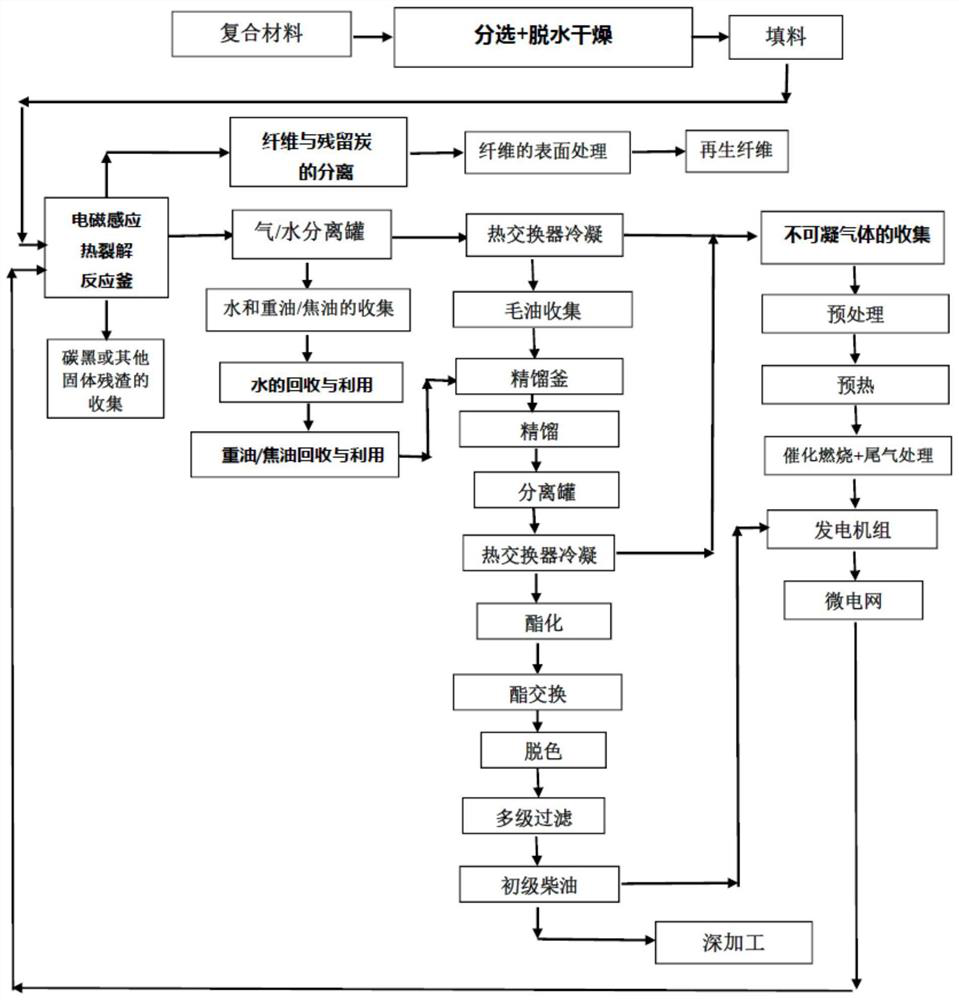

A technology of composite materials and material tanks, applied in the field of energy and chemical industry, can solve the problems of no industrial application, etc., and achieve the effect of high energy utilization rate and environmental protection of process flow

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

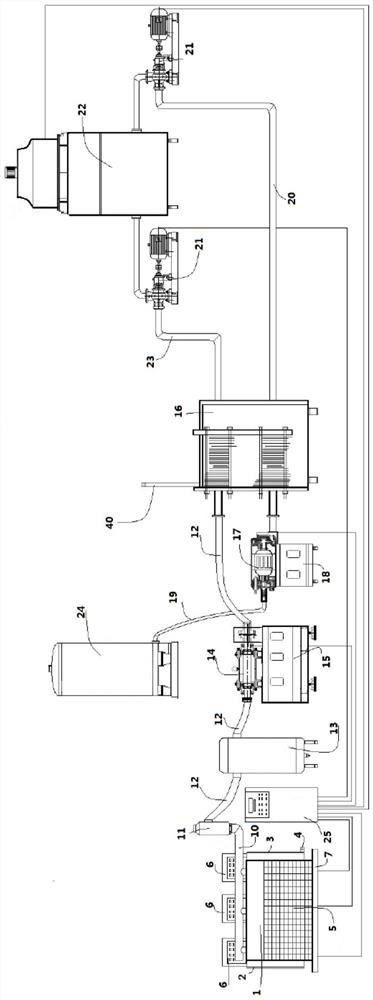

Embodiment 1

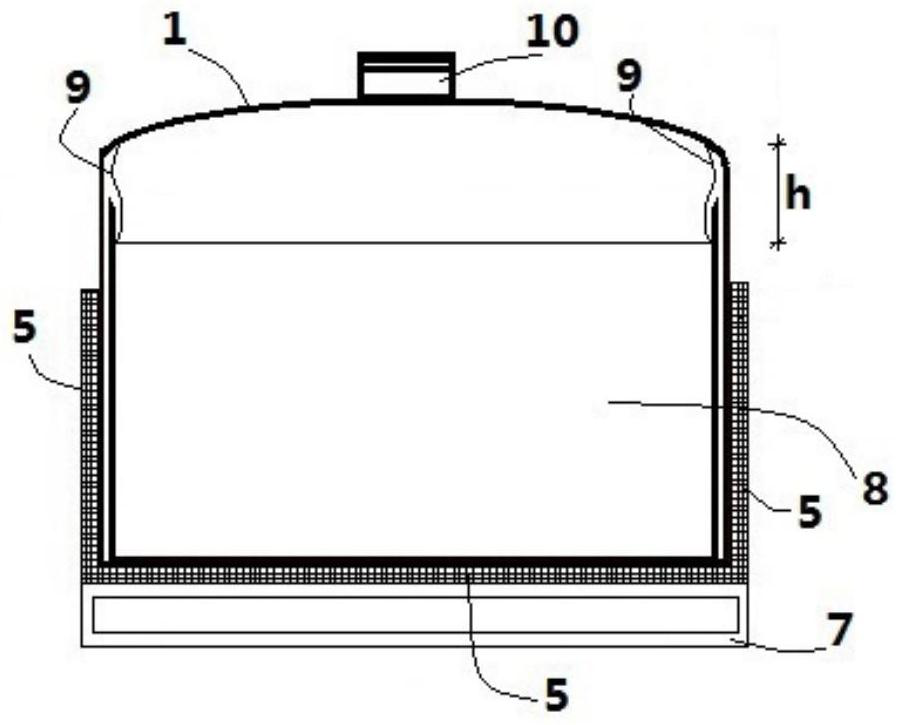

[0095] First, various composite fiber raw materials matching the length of the material trough 8 are sorted out. The composite fiber raw material is dehydrated and dried in advance. Then the raw materials are loaded into the material tank 8 and sent into the body of the thermal cracking reactor 1, and the feed door 2 of the thermal cracking reactor can be opened at 180°. The main part of the reactor body of the thermal cracking reactor 1 is a cuboid for carrying the material tank 8 . The top of the still body of the pyrolysis reactor 1 is an elliptical vault top, and its cross section is as follows: image 3 shown. Now open the high temperature resistant centrifugal induced draft fan 14 to extract the air in the still body, so that the pressure value in the still body reaches the low vacuum pressure range. Then use the flat-plate electromagnetic induction heating jacket 5 to heat the composite fiber raw material in the still body of the pyrolysis reactor 1 to 400°C-450°C in...

Embodiment 2

[0102] Because thermal cracking crude oil is a mixture of aliphatic, aromatic and polar compounds with a boiling point between about 70°C and 400°C, it is dark brown in color and strongly irritating. Therefore, it is difficult to find wider applications without purification. Firstly, the crude oil stored in the crude oil storage tank 24 is pumped into the still body of the crude oil rectification kettle 26 from the crude oil feed port 28 by an oil pump. The kettle body of the crude oil rectifying kettle 26 is a horizontal cylinder, and a radar level gauge 33 is installed on the top of the kettle. The rectification needs to gradually increase the temperature of the crude oil from normal temperature to 200°C-350°C. In this embodiment, the temperature of 290°C-300°C is used for rectification. The temperature rise of the crude oil rectification kettle 26 is provided by a high-power semi-circular electromagnetic heating jacket 31, and the temperature, time and power required for h...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com