Tin-manganese stannate-nitrogen carbon composite material with hollow cubic structure as well as preparation method and application thereof

A technology of composite materials and cubes, applied in nanotechnology, structural parts, active material electrodes, etc. for materials and surface science, can solve poor performance and unstudied electrochemical performance of tin-carbon composite nanoparticles sodium-ion battery anode materials And other issues

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

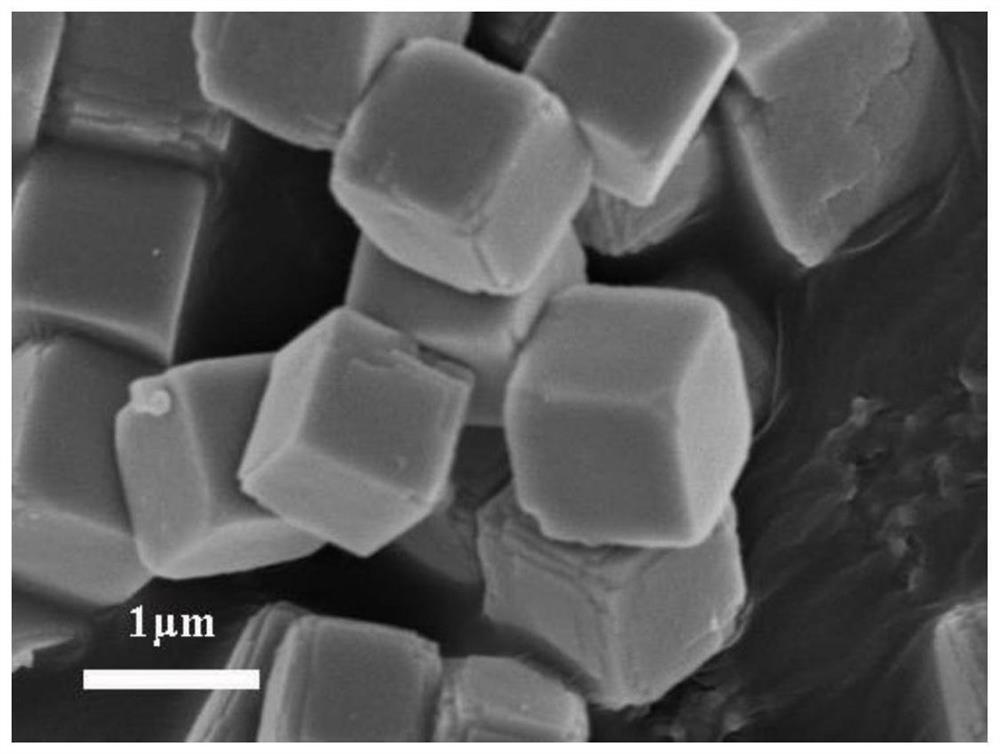

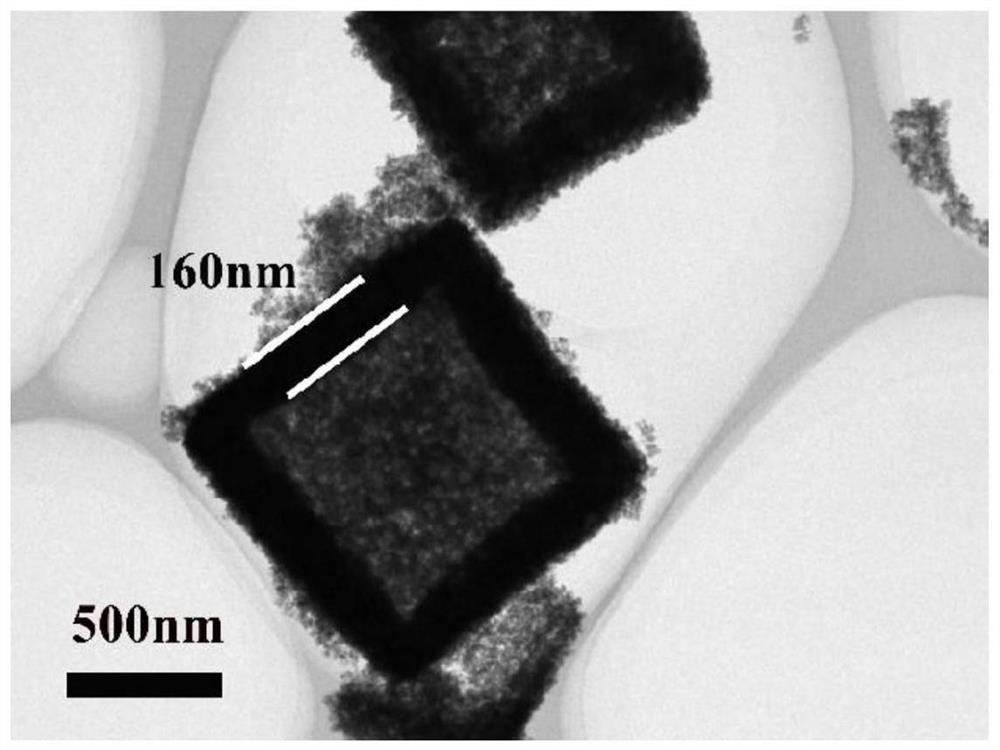

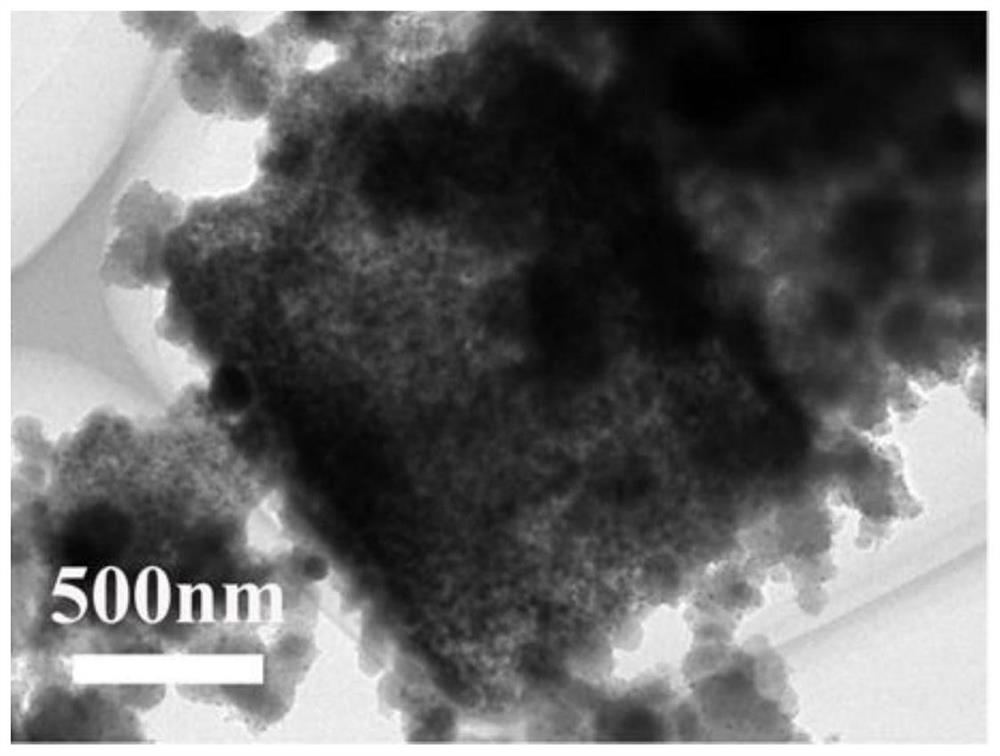

[0042] A hollow cubic structure of Sn@Mn 2 SnO 4 -The preparation method of NC composite material specifically comprises the following steps:

[0043] S1. Add 10ml of 0.2M SnCl 4 ·5H 2 O solution and 80ml containing 0.025M ZnCl 2 Mix with a solution of 0.025M citric acid, and after stirring evenly, add 40ml of 0.5M NaOH solution to the above solution, and after centrifugation, washing and drying, ZnSn(OH) 6 white solid precipitate;

[0044] S2. The obtained ZnSn(OH) 6 Oxidation at 600°C in air yields SnO 2 @Zn 2 SnO 4 ; 464 mg SnO 2 @Zn 2 SnO 4 Disperse in 50ml of water, add 1.315g of EDTA, transfer to a reaction kettle and heat to 220°C for 12h, after washing and drying, SnO 2 ;

[0045] S3. 100mg SnO 2 with 200mg K 2 MnO 4 After mixing evenly, add 100 microliters of 37% HCl solution and heat to 110°C for 6 hours. After washing and drying, SnO 2 @MnO 2 ;

[0046] S4. Add 100mg of SnO 2 @MnO 2 Ultrasonic dispersion in 100mL Tris buffer, after 10 minutes of...

Embodiment 2

[0050] A hollow cubic structure of Sn@Mn 2 SnO 4 -The preparation method of NC composite material specifically comprises the following steps:

[0051] S1. Add 10ml of 0.2M SnCl 4 ·5H 2 O solution and 80ml containing 0.05M ZnCl 2 Mix with 0.05M citric acid solution, stir evenly, then add 40ml 1M NaOH solution to the above solution, after centrifugation, washing and drying, ZnSn(OH) 6 white solid precipitate;

[0052] S2. The obtained ZnSn(OH) 6 The product is oxidized at 300°C in air to obtain SnO 2 @Zn 2 SnO 4 ; 464mg SnO 2 @Zn 2 SnO 4 Disperse in 50ml of water, add 1.753g of EDTA, transfer to a reaction kettle and heat to 200°C for 12h, after washing and drying, SnO 2 ;

[0053] S3. 100mg SnO 2 with 200mg K 2 MnO 4 After mixing evenly, add 80 microliters of 37% HCl solution and heat to 120°C for 6 hours. After washing and drying, SnO 2 @MnO 2 ;

[0054] S4. Add 100mg of SnO 2 @MnO 2 Ultrasonic dispersion in 100mL Tris buffer, after ultrasonication for 10 ...

Embodiment 3

[0057] A hollow cubic structure of Sn@Mn 2 SnO 4 -The preparation method of NC composite material specifically comprises the following steps:

[0058] S1. Add 10ml of 0.2M SnCl 4 ·5H 2 O solution and 80ml containing 0.025M ZnCl 2 Mix with 0.1M citric acid solution, stir evenly, then add 30ml 2M NaOH solution to the above solution, after centrifugation, washing and drying, ZnSn(OH) 6 white solid precipitate;

[0059] S2. The obtained ZnSn(OH) 6 The product is oxidized at 800°C in air to obtain SnO 2 @Zn 2 SnO 4 ; 464mg SnO 2 @Zn 2 SnO 4Disperse in 50ml of water, add 1.753g of EDTA, transfer to a reaction kettle and heat to 220°C for 12h, after washing and drying, SnO 2 ;

[0060] S3. 100mg SnO 2 with 200mg K 2 MnO 4 After mixing evenly, add 80 microliters of 37% HCl solution and heat to 160°C for 6 hours. After washing and drying, SnO 2 @MnO 2 ;

[0061] S4. Add 100mg of SnO 2 @MnO 2 Ultrasonic dispersion in 100mL Tris buffer, after 10 minutes of ultrasonic...

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com