Method for removing parylene film layer on surface of PCBA

A technology of parylene and film layer, which is applied in the field of removal of parylene film layer on the surface of PCBA board, can solve the problems of damaged PCBA board, expensive laser equipment, high cost of film removal, etc., achieves low cost, simple method and reduced production cost effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0057] The method for removing the parylene film on the surface of the PCBA board of the present embodiment is as follows:

[0058] (1) PCBA board is provided. The surface of the PCBA board is provided with a parylene N-type film layer. The parylene film layer has a preset area to be removed, and the thickness of the parylene film layer in the area to be removed is 8 μm

[0059] (2) Cover the PCBA board with a shielding cover, the material of the shielding cover is Teflon, and the shielding cover is provided with a through hole, and the position of the through hole corresponds to the position of the area to be removed.

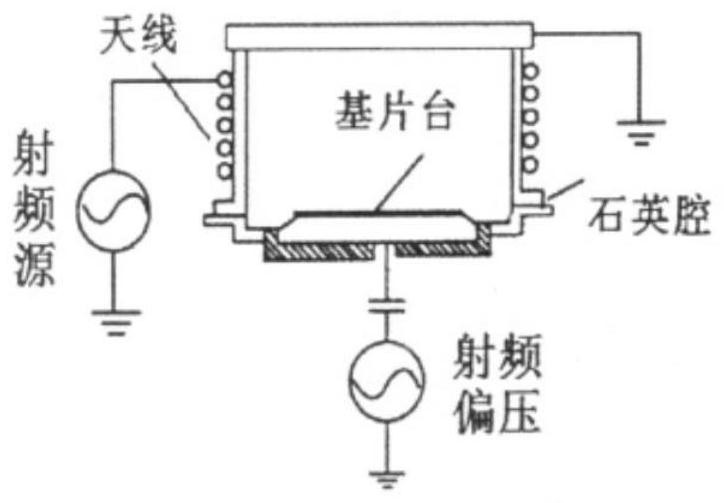

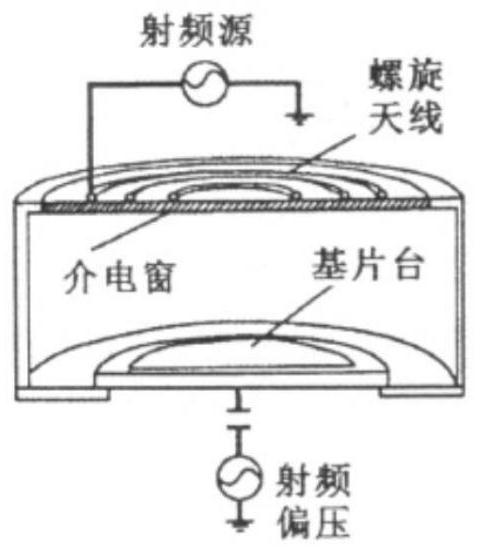

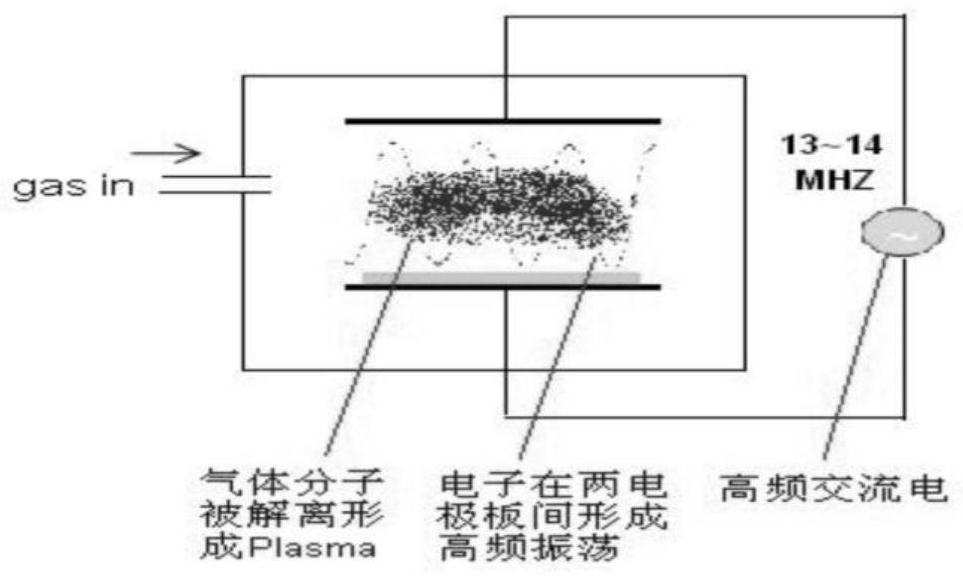

[0060] (3) Perform plasma etching on the above-mentioned PCBA board in the flat PECVD system, under the protection of the mask, only the parylene film layer at the corresponding position of the through hole is etched. During the etching process, no bias power supply and inductor are added, the oxygen flow rate is 250sccm, and the fluorine-containing gas CF 4 ...

Embodiment 2

[0063] The method for removing the parylene film on the surface of the PCBA board of the present embodiment is as follows:

[0064] (1) A PCBA board is provided, and the surface of the PCBA board is provided with a parylene N-type film layer. The parylene film layer has a preset area to be removed, and the thickness of the parylene film layer in the area to be removed is 8 μm.

[0065] (2) Cover the PCBA board with a shielding cover, the material of the shielding cover is TPU, and the shielding cover is provided with a through hole, and the position of the through hole corresponds to the position of the area to be removed.

[0066] (3) In the flat PECVD system, the above-mentioned PCBA board is plasma etched. During the etching process, no bias power supply and inductor are added, the oxygen flow rate is 250 sccm, and the fluorine-containing gas CF 4 The flow rate is 40sccm, the flow rate of argon gas is 0, the radio frequency power is 450W, and the working pressure is 32Pa. ...

Embodiment 3

[0069] The method for removing the parylene film on the surface of the PCBA board of the present embodiment is as follows:

[0070] (1) A PCBA board is provided, and the surface of the PCBA board is provided with a parylene N-type film layer. The parylene film layer has a preset area to be removed, and the thickness of the parylene film layer in the area to be removed is 8 μm.

[0071] (2) Cover the PCBA board with a shielding cover, the material of the shielding cover is Teflon, and the shielding cover is provided with a through hole, and the position of the through hole corresponds to the position of the area to be removed.

[0072](3) Perform plasma etching on the above-mentioned PCBA board in a flat PECVD system. During the etching process, no bias power supply and inductor are added, the oxygen flow rate is 250 sccm, and the fluorine-containing gas SF 6 The flow rate is 63sccm, the flow rate of argon gas is 0, the radio frequency power is 450W, and the working pressure is...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com