Device and process for preparing silicon carbide by PVT method

A technology of silicon carbide and carbide, which is applied in the field of PVT preparation of silicon carbide device and preparation process, can solve the problems of micropipes, carbon-wrapped growth defects, etching, etc., to ensure doping stability and resistivity distribution uniformity , reduce cost and prolong service life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

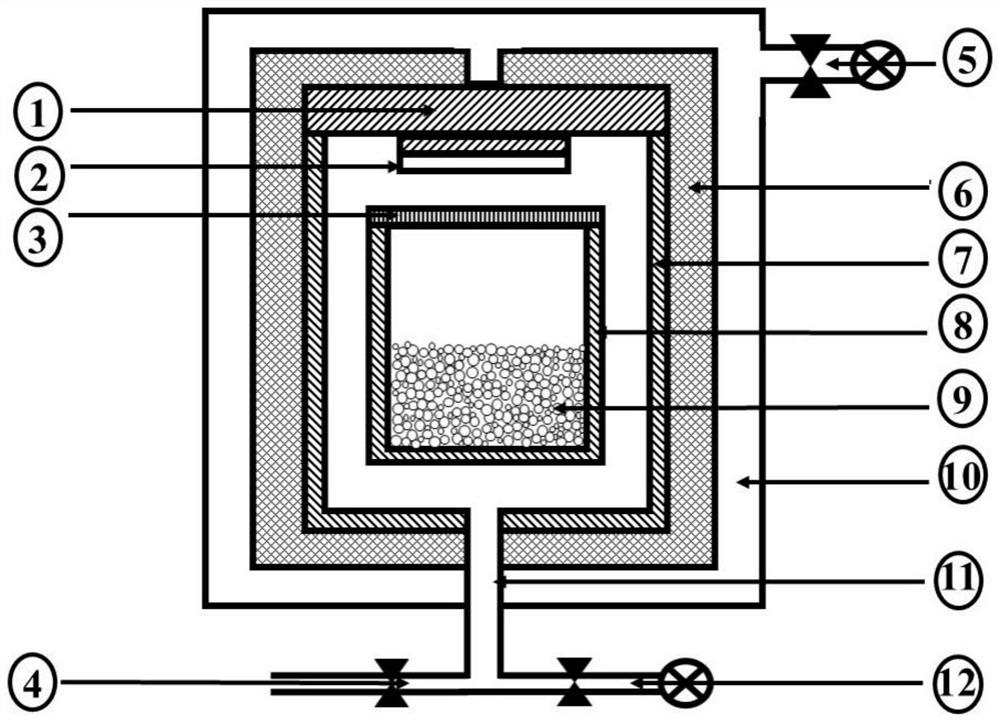

[0035] like figure 1 As shown, the present embodiment provides a device for preparing silicon carbide by PVT method, which includes a furnace body 10, an insulating layer, a growth crucible 7, a raw material crucible 8 and a porous gas permeable layer 3; the furnace body 10 is provided with an insulating layer, and the insulating layer is provided with There is a growth crucible 7, the raw material crucible 8 is located in the growth crucible 7, the porous gas permeable layer 3 is arranged at the top opening of the raw material crucible 8; the furnace body 10 is communicated with a vacuum system 5 of a furnace body 10, and the bottom of the growth crucible 7 is connected with a crucible The vacuum system 12 is in communication. The silicon carbide seed crystal 2 is grown on the bottom of the growth crucible cover 1 on the top of the growth crucible 7 .

[0036] In this embodiment, the furnace body 10 includes an upper furnace cover, a main furnace body 10 and a lower furnace ...

Embodiment 2

[0057] Using the device in the first embodiment to prepare a semi-insulating silicon carbide crystal, the steps are as follows:

[0058] 1. Add the self-made high-purity silicon carbide powder 9 into the raw material crucible 8. The particle size of the silicon carbide powder 9 ranges from 5 to 200 mesh, the purity is greater than 99.9999%, and the bulk density is 1.2 g / cm 3 . After charging, a graphite sheet with a thickness of 2 mm and a tantalum carbide coating was placed on top of the powder.

[0059] 2. Put the raw material crucible 8 in the growth crucible 7, and the growth crucible 7 is sealed with bolts and glue;

[0060] 3. Put the thermal field composed of the growth crucible 7 and the heat insulating material 6 into the furnace body 10, and the bottom of the growth crucible 7 is connected and sealed with the gas inlet and outlet pipes, and the sealing method is graphite paper with bolt pads.

[0061] 4. Close the upper and lower furnace covers and seal them throug...

PUM

| Property | Measurement | Unit |

|---|---|---|

| density | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com