Hydrogen energy power overhead line system maintenance operation vehicle for railway

A technology of hydrogen energy and catenary, applied in the field of rail engineering, can solve problems such as the inconvenient integration and application of hydrogen gas systems

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

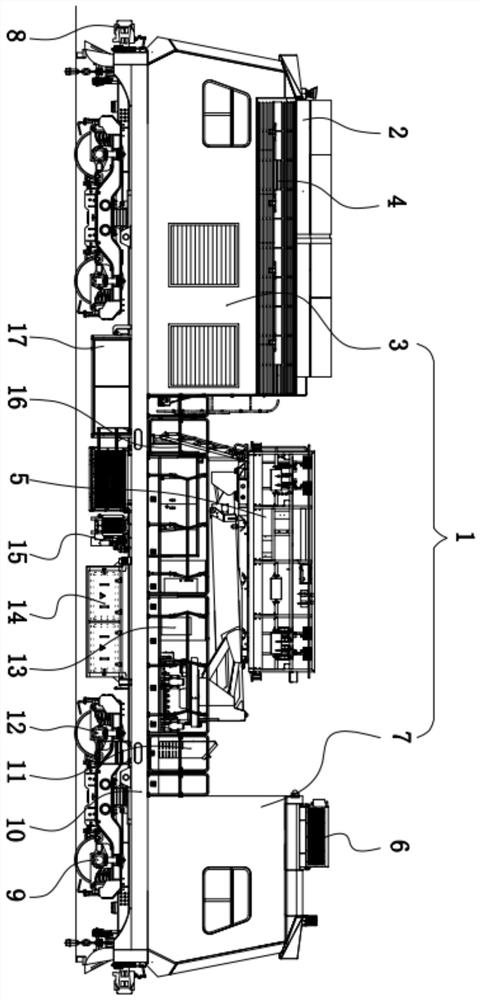

[0043] Provide a 300kW power level hydrogen energy power catenary maintenance work vehicle for railways:

[0044] The maximum operating speed is 120km / h, the weight of the whole vehicle is about 58 tons, the minimum curve radius can pass 100m, and the cruising range can reach more than 700km.

[0045] Operating equipment suitable for tunnel full-section and sound barrier maintenance;

[0046] Through the integration scheme of a high-power hydrogen fuel cell system on the car, the weight of the car is less than 58t, and the length of the car meets the curve radius of 100m. At the same time, the vehicle limit complies with GB146.1 "Standard Gauge Railway Limit Part 1 Locomotives According to the provisions of "Vehicle Limits", it has good stability, safety and good maintenance performance.

[0047] Ensure the safety of hydrogen energy-powered catenary maintenance vehicles.

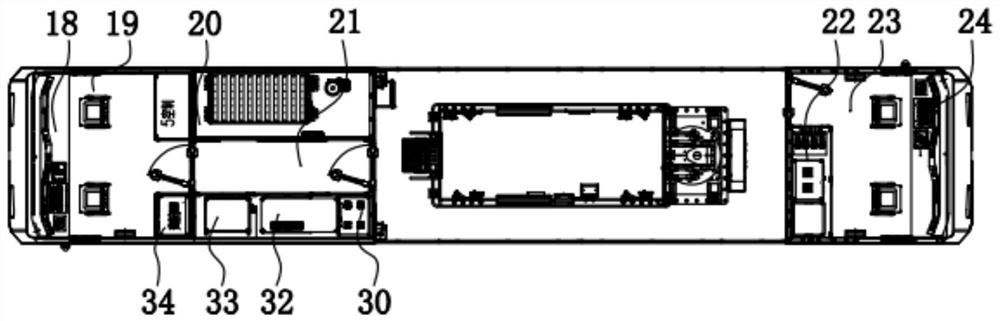

[0048] A hydrogen energy powered catenary maintenance vehicle for railways includes: a car shed 1 and a...

Embodiment 2

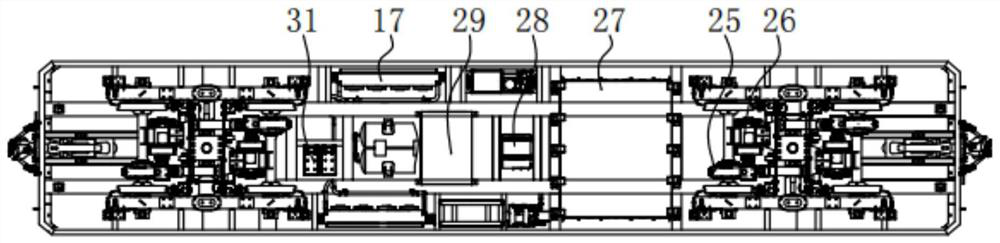

[0097] The bottom of the vehicle frame 10 is provided with a braking system 15, which is composed of a CAB-B braking system, a resistance braking system and a basic braking device, and can realize air-electric interlocking control.

[0098] When the electric brake is applied during normal driving, the CCU controls and drives the air-electric interlock valve to act, and the normal air brake of the gate is removed; when the emergency brake is applied through the gate, or the emergency brake button is pressed, or the emergency Stop button, or when the brake pressure of the small brake is greater than 90KPa, the system will automatically cut off the electric brake.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com