Biological humic acid fertilizer and preparation method thereof

A technology of biological humic acid and humic acid, applied in the direction of ammonium orthophosphate fertilizer, alkaline orthophosphate fertilizer, organic fertilizer, etc., can solve the problems of insignificant application effect, short fertilizer effect time, and unstable fertilizer effect.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

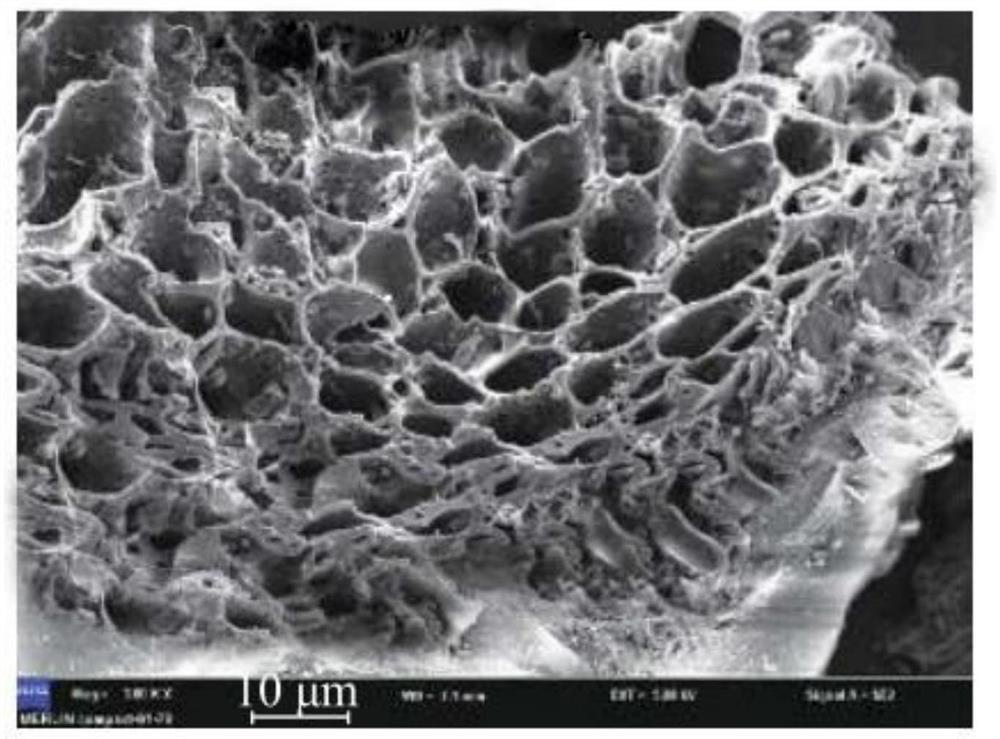

Image

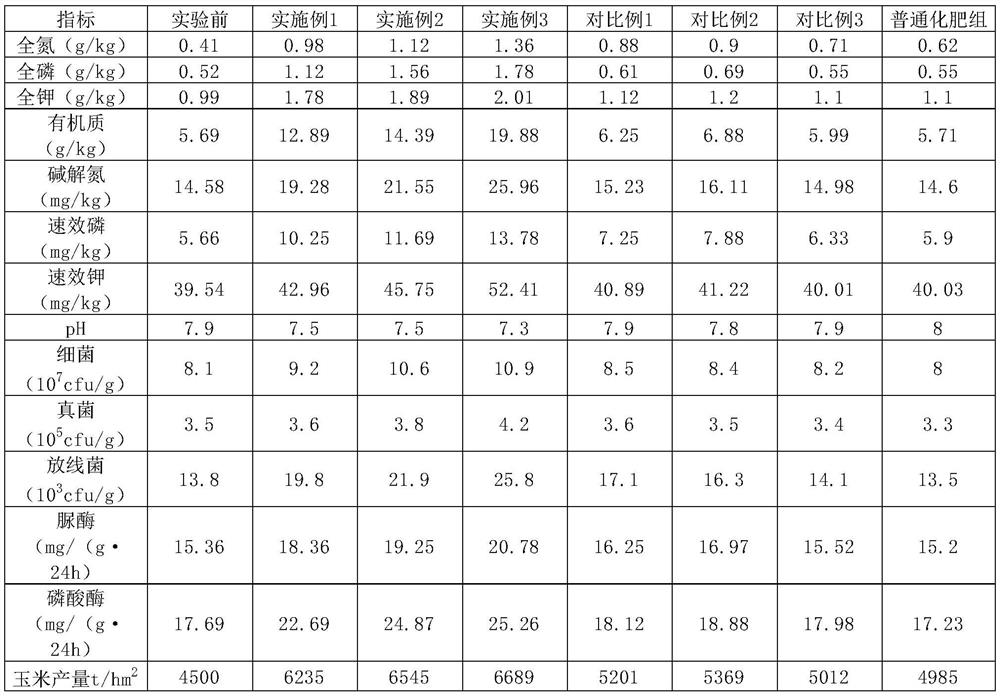

Examples

Embodiment 1

[0035] A biological humic acid fertilizer, prepared from the following raw materials in parts by weight: 200 parts of straw fermented humic acid, 50 parts of urea, 40 parts of monoammonium phosphate, 50 parts of potassium sulfate, 50 parts of bentonite, 20 parts of medium elements, trace elements 10 parts of elements, 10 parts of biological agents, 5 parts of polyglutamic acid.

[0036]The preparation method of the stalk fermented humic acid is as follows: dry the corn stalks and pulverize them, add 0.1wt% Trichoderma viride and 0.1wt% Bacillus thuringiensis, adjust the water content to 50%, aerobically or Facultatively ferment for 8 days, and dry the water to obtain straw fermented humic acid.

[0037] The Trichoderma viride and Bacillus thuringiensis can be commercially available bacteria powder.

[0038] The bentonite is pretreated bentonite, and the pretreatment method is as follows: put the bentonite in a heating furnace, calcinate for 9 minutes at 500° C. under anaerobi...

Embodiment 2

[0049] A biological humic acid fertilizer, prepared from the following raw materials in parts by weight: 250 parts of straw fermented humic acid, 70 parts of urea, 50 parts of monoammonium phosphate, 80 parts of potassium sulfate, 60 parts of bentonite, 25 parts of medium elements, trace elements 15 parts of elements, 15 parts of biological agents, and 8 parts of polyglutamic acid.

[0050] The preparation method of the stalk fermented humic acid is as follows: dry the corn stalks and pulverize them, add 0.2wt% Trichoderma viride and 0.3wt% Bacillus thuringiensis, adjust the water content to 70%, and aerobically or Facultatively ferment for 14 days, dry the moisture to obtain straw fermented humic acid.

[0051] The Trichoderma viride and Bacillus thuringiensis can be commercially available bacteria powder.

[0052] The bentonite is pretreated bentonite, and the pretreatment method is as follows: put the bentonite in a heating furnace, calcinate for 9 minutes at 500° C. under...

Embodiment 3

[0063] A biological humic acid fertilizer, prepared from the following raw materials in parts by weight: 300 parts of straw fermented humic acid, 80 parts of urea, 60 parts of monoammonium phosphate, 100 parts of potassium sulfate, 70 parts of bentonite, 30 parts of medium elements, trace elements 20 parts of elements, 20 parts of biological agents, and 10 parts of polyglutamic acid.

[0064] The preparation method of the stalk fermented humic acid is as follows: dry the corn stalks and pulverize them, add 0.2wt% Trichoderma viride and 0.3wt% Bacillus thuringiensis, adjust the water content to 70%, and aerobically or Facultatively ferment for 14 days, dry the moisture to obtain straw fermented humic acid.

[0065] The Trichoderma viride and Bacillus thuringiensis can be commercially available bacteria powder.

[0066] The bentonite is pretreated bentonite, and the pretreatment method is as follows: put the bentonite in a heating furnace, calcinate for 9 minutes at 500° C. und...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com