Method for efficiently preparing melanin under photo-induction

A melanin, light-induced technology, applied in chemical instruments and methods, azo dyes, organic dyes, etc., can solve the problems of difficult purification, cumbersome and time-consuming melanin production process, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

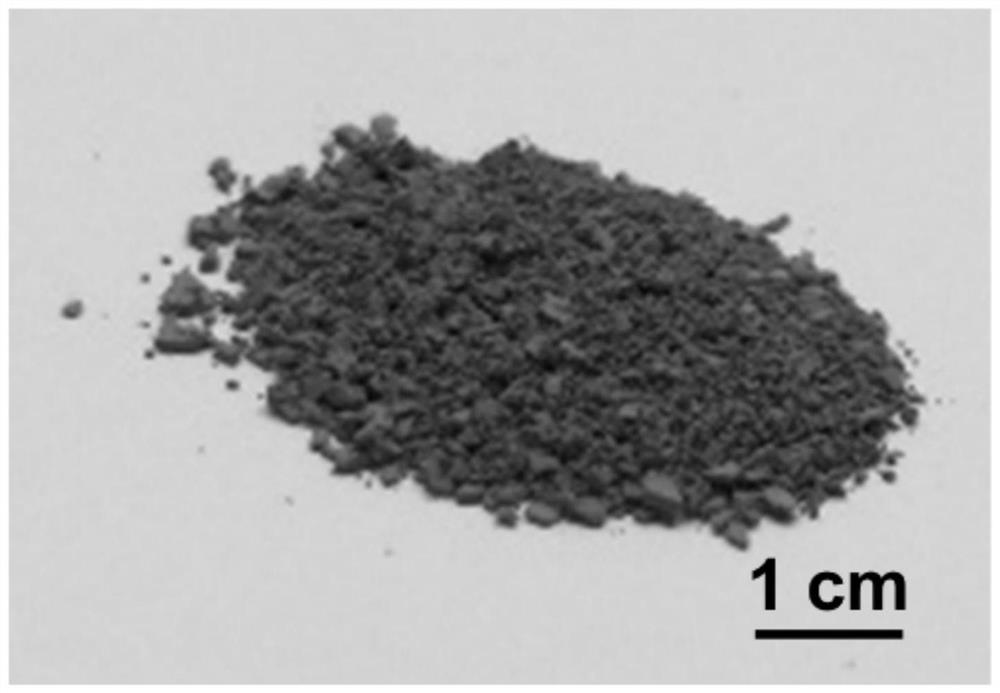

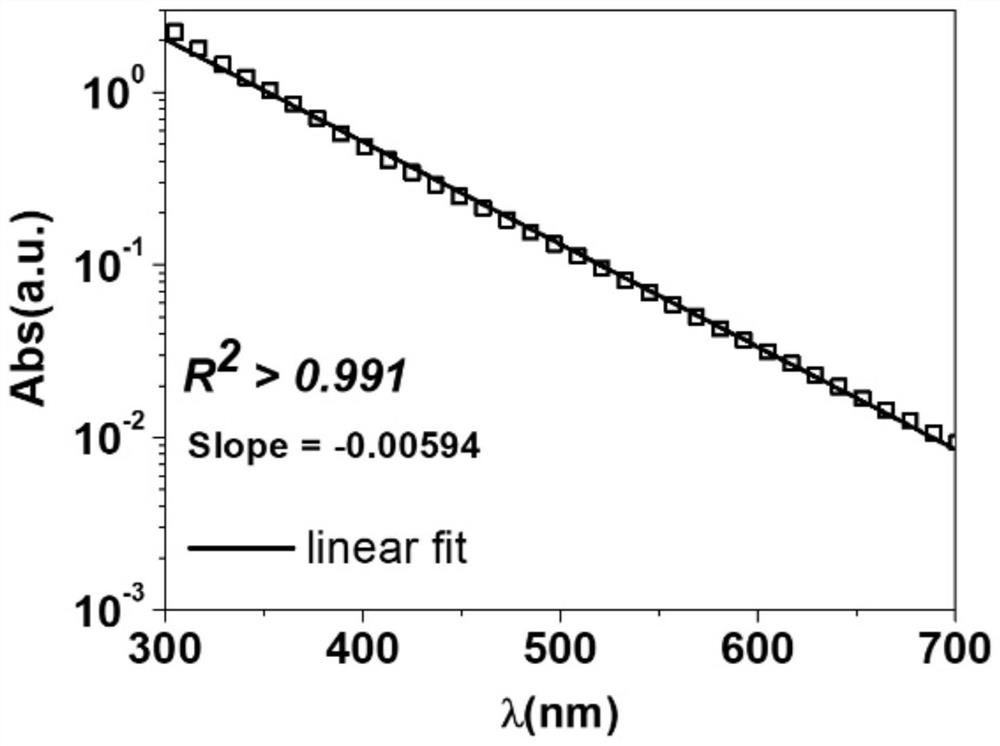

Image

Examples

Embodiment 1

[0031] (1) Take 0.05g L-tyrosine as raw material;

[0032] (2) Using 0.005g terpyridyl ruthenium chloride (Ru(II)) and 0.005g potassium persulfate (KPS) as the photoinitiating system;

[0033] (3) Dissolve the photoinitiating system and L-tyrosine in 100mL deionized water sequentially, sonicate until clear and transparent, and then irradiate with a 50W 465nm blue LED for 10min to obtain a reaction mixture;

[0034] (4) Centrifuge the above reaction mixture at a temperature of 20° C., a rotation speed of 10,000 r / min, and a time of 20 minutes. Remove the centrifuged supernatant, and wash and filter the centrifuged solid precipitate 3 times with absolute ethanol. The filtered product was dried at 60°C to finally obtain melanin with a yield of 50.3%.

Embodiment 2

[0036] (1) Take 2.0g L-phenylalanine and 1.0g L-tryptophan as raw materials;

[0037] (2) With 0.001g (2,2'-bipyridyl)bis[2-(2,4-difluorophenyl)pyridine]iridium(III) hexafluorophosphate (Ir(III)) and 0.01g persulfuric acid Ammonium (APS) is the photoinitiating system;

[0038] (3) Dissolve the photoinitiating system, L-phenylalanine and L-tryptophan in 100mL of deionized water in turn, sonicate until clear and transparent, and irradiate under a 100W 350-800nm xenon lamp (with filter) 10min obtains reaction mixture;

[0039] (4) Centrifuge the above reaction product at a temperature of 20° C., a rotation speed of 10,000 r / min, and a time of 20 minutes. The centrifugation supernatant was removed, and the centrifuged solid precipitate was filtered three times with deionized water. The filtered product was dried at 60°C to finally obtain melanin with a yield of 70.7%.

Embodiment 3

[0041] (1) Take 2.0g L-tryptophan, 0.1g L-tyrosine and 20.0g L-alanine as raw materials;

[0042] (2) With 0.0005g camphorquinone (CQ) and 0.05g 4-dimethylamino-ethyl benzoate (EDMAB) as photoinitiating system;

[0043] (3) Dissolve the photoinitiating system and each amino acid in 200mL of deionized water in turn, after ultrasonication until clear and transparent, irradiate for 10 minutes under a 100W 395nm ultraviolet LED to obtain a reaction mixture;

[0044] (4) Centrifuge the above reaction product at a temperature of 20° C., a rotation speed of 10,000 r / min, and a time of 20 minutes. The centrifugation supernatant was removed, and the centrifuged solid precipitate was filtered three times with deionized water. The filtered product was dried at 60°C to finally obtain melanin with a yield of 73.3%.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com