Method for wet recovery of lithium elements from scrapped lithium iron phosphate batteries

A lithium iron phosphate battery, lithium iron phosphate technology, applied in battery recycling, waste collector recycling, non-metallic elements and other directions, can solve the problems of complex process, low lithium recovery rate and high recovery cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

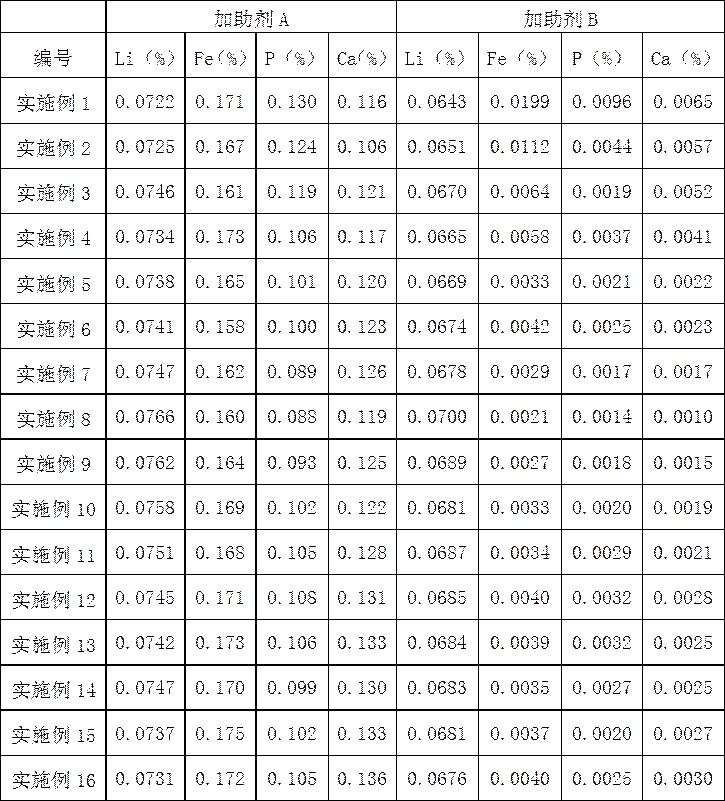

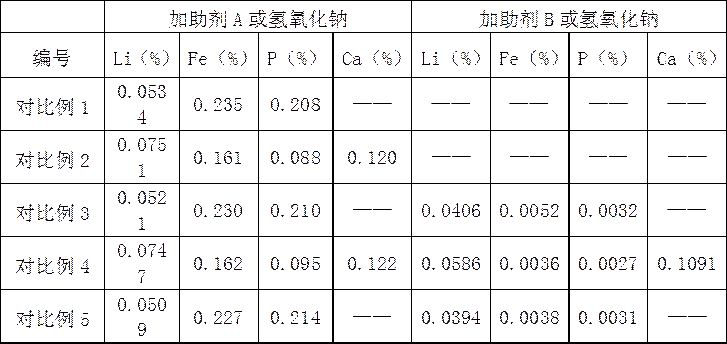

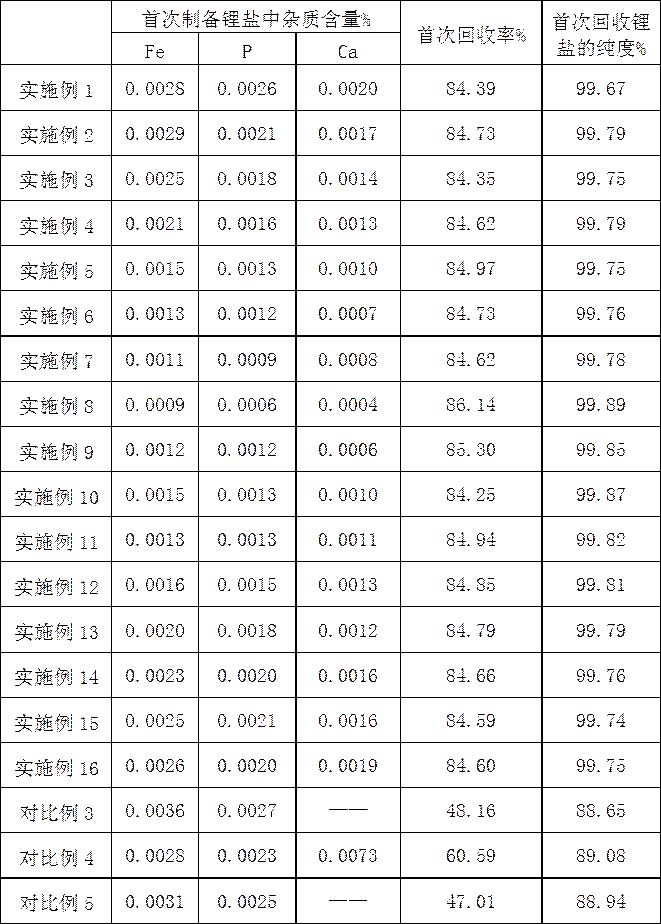

Examples

Embodiment 1

[0023] 1) Take ethylene carbonate (CE) 10%, bentonite 1%, calcium hydroxide (Ca(OH) 2 ) 87.7%, ethylenediaminetetraacetic acid (EDTA) 1%, dispersant CNF0.1% (purchased from Guangzhou Lihongji Chemical Co., Ltd.), AGITAN P803 0.1% (purchased from Nanjing Yuelai New Material Technology Co., Ltd.), fatty acid Polyoxyethylene ester 0.1%, mix the raw materials taken evenly, and ball mill at 250r / min for 1h to obtain 20g of additive A;

[0024] 2) Take ethylene carbonate (CE) 0.1%, ethylenediaminetetraacetic acid (EDTA) 1%, sodium hydroxide (NaOH) 97.6%, ammonium bicarbonate (NH 4 HCO 3 ) 1%, polyacrylamide ((C 3 h 5 NO)n) 0.1%, sodium dodecylbenzenesulfonate 0.1%, organopolysiloxane 0.1%, mix the raw materials evenly, and ball mill at 250r / min for 1h to obtain 20g of additive B;

[0025] 3) Take 15.7760g of lithium iron phosphate positive electrode active material and use sulfuric acid with a mass concentration of 2% for acid leaching. The molar mass ratio of lithium iron phosp...

Embodiment 2

[0031] 1) Take ethylene carbonate (CE) 10%, bentonite 1%, calcium hydroxide (Ca(OH) 2 ) 87.7%, ethylenediaminetetraacetic acid (EDTA) 1%, dispersant CNF0.1%, AGITAN P803 0.1%, fatty acid polyoxyethylene ester 0.1%, the raw materials were mixed evenly, 300r / min ball milled for 1h, and the auxiliary Agent A20g;

[0032] 2) Take ethylene carbonate (CE) 0.1%, ethylenediaminetetraacetic acid (EDTA) 1%, sodium hydroxide (NaOH) 97.6%, ammonium bicarbonate (NH 4 HCO 3 ) 1%, polyacrylamide ((C 3 h 5 NO)n) 0.1%, sodium dodecylbenzenesulfonate 0.1%, organopolysiloxane 0.1%, mix the raw materials evenly, and ball mill at 300r / min for 1h to obtain additive B20g

[0033] 3) Take 15.7760g of lithium iron phosphate positive electrode active material and use sulfuric acid with a mass concentration of 2% for acid leaching. The molar mass ratio of lithium iron phosphate to sulfuric acid is 1:2, the reaction time is 1h, the reaction temperature is 45°C, and the reaction ends After filtering,...

Embodiment 3

[0039] 1) Take ethylene carbonate (CE) 10%, bentonite 1%, calcium hydroxide (Ca(OH) 2 ) 87.7%, ethylenediaminetetraacetic acid (EDTA) 1%, dispersant CNF0.1%, AGITAN P803 0.1%, fatty acid polyoxyethylene ester 0.1%, the raw materials were mixed evenly, 350r / min ball milled for 1h, and the auxiliary Agent A20g;

[0040] 2) Take ethylene carbonate (CE) 0.1%, ethylenediaminetetraacetic acid (EDTA) 1%, sodium hydroxide (NaOH) 97.6%, ammonium bicarbonate (NH 4 HCO 3 ) 1%, polyacrylamide ((C 3 h 5 NO)n) 0.1%, sodium dodecylbenzenesulfonate 0.1%, organopolysiloxane 0.1%, mix the raw materials evenly, and ball mill at 350r / min for 1h to obtain 20g of additive B;

[0041] 3) Take 15.7760g of lithium iron phosphate positive electrode active material and use sulfuric acid with a mass concentration of 2% for acid leaching. The molar mass ratio of lithium iron phosphate to sulfuric acid is 1:2, the reaction time is 1h, the reaction temperature is 45°C, and the reaction ends After filte...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com