Transcritical carbon dioxide heat pump driven system for preparing ice slurry through rotary wheel dehumidification and evaporation

A carbon dioxide and rotary dehumidification technology, which is used in ice making, ice making, evaporator/condenser, etc. It can solve the problems of high concentration of dehumidification solution, ice blockage of evaporator pipes, and large mechanical power consumption.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

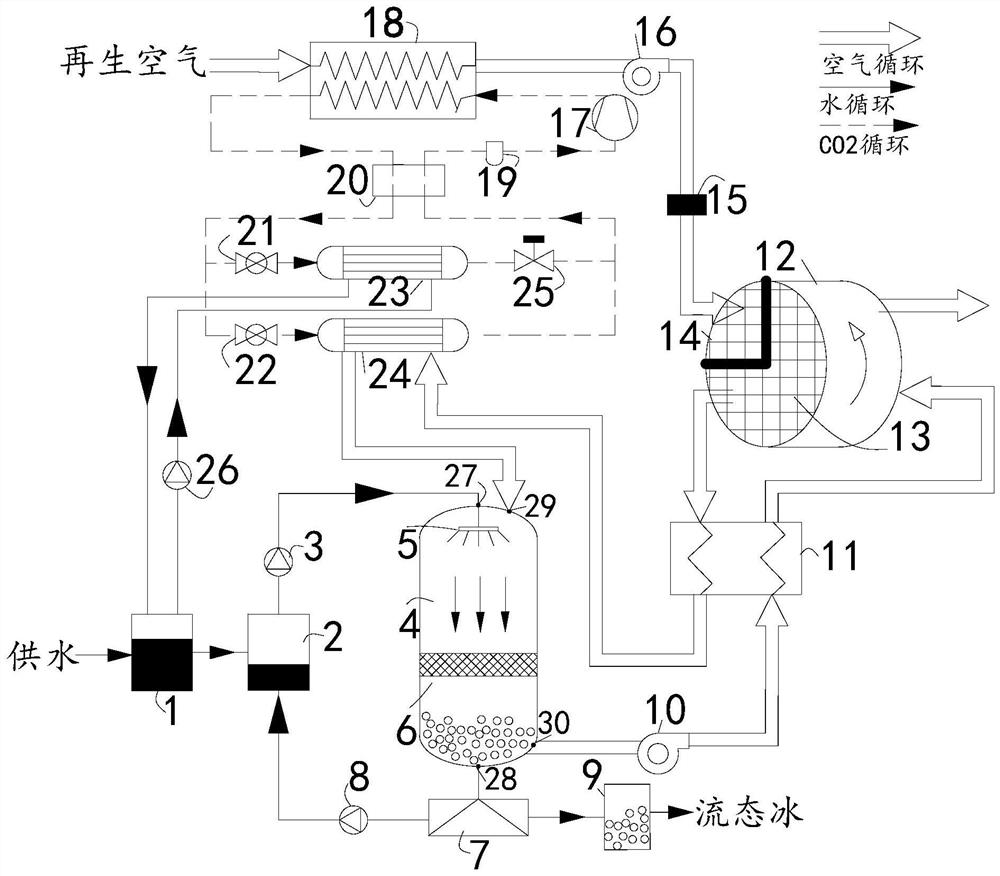

[0022] Such as figure 1 As shown, a system schematic diagram of a transcritical carbon dioxide heat pump-driven rotary dehumidification and evaporation system for producing liquid ice, in this embodiment, includes a heat pump precooling and heat recovery system, an evaporative ice making system, and a rotary dehumidification system ;

[0023]The heat pump pre-cooling and heat recovery system uses carbon dioxide as the circulating working medium. On the one hand, it pre-cools the circulating water and circulating air; on the other hand, it heats the regeneration air through heat recovery at a transcritical high temperature; The system includes a water storage tank 1, a compressor 17, a gas cooler 18, a gas-liquid separator 19, a regenerator 20, a first throttle valve 21, a second throttle valve 22, a water-cooled evaporator 23, an air-cooled evaporator 24, Pressure regulating valve 25 and circulating water pump 26. First, the refrigerant carbon dioxide is compressed by the co...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com