Process and equipment for preparing bromoethane

A technology of bromoethane and equipment is applied in the field of technology and equipment for preparing bromoethane, and can solve the problems of single mixing structure and inability to combine gas mixing structures and the like

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

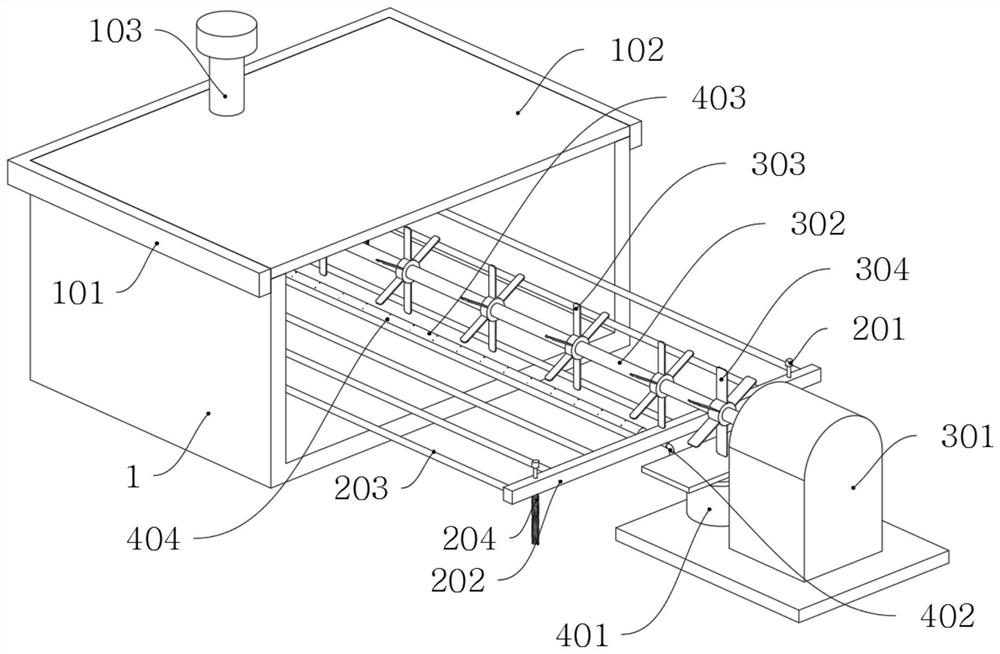

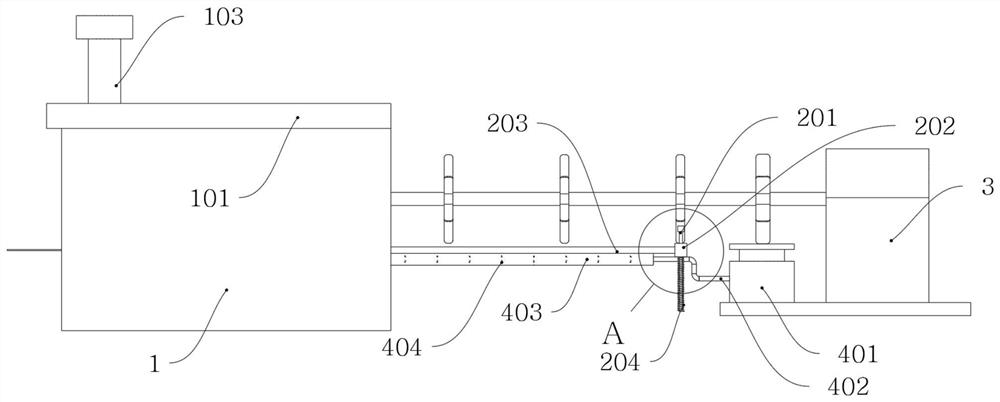

[0058] as attached figure 1 to attach Figure 8 Shown:

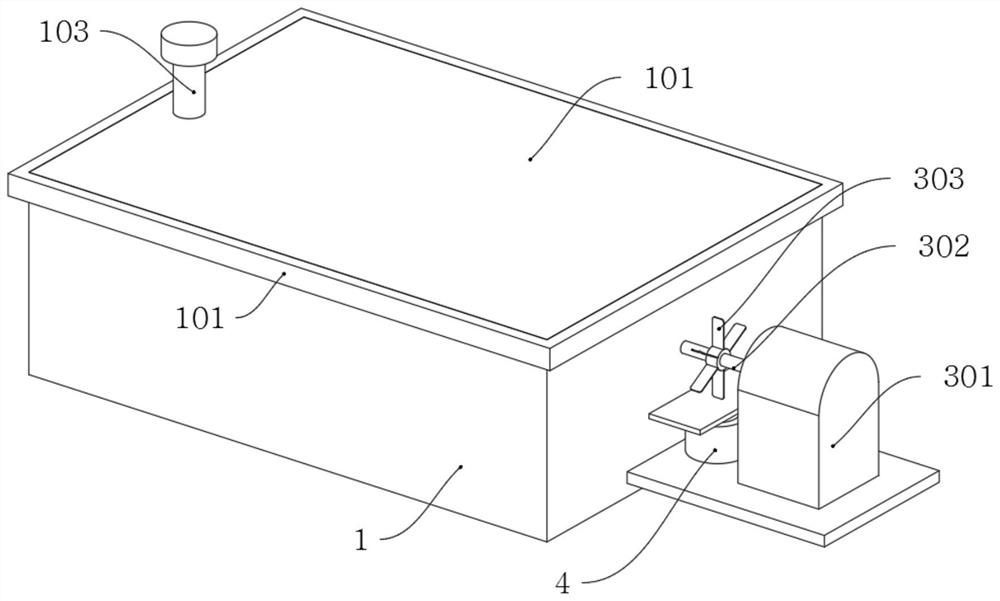

[0059] The invention provides a process and equipment for preparing bromoethane, including a box body 1;

[0060] The box body 1 is a rectangular box-like structure;

[0061] The heating structure 2, the heating structure 2 is installed in the box body 1;

[0062] The driving structure 3 is installed on the box body 1 .

[0063] Reference as figure 2 , box 1 includes:

[0064] The cover plate 102, the cover plate 102 is a rectangular plate structure, and the cover plate 102 is fixedly connected to the box body 1 by bolts;

[0065] The protective seat 101, the protective seat 101 is welded on the box body 1, and the protective seat 101 is a back-shaped structure, and the inner wall of the protective seat 101 is in contact with the front end face, the rear end face, the left end face and the right end face of the cover plate 102, so that the cover can be improved. The sealing performance between the plate 102 and t...

Embodiment 2

[0093] A kind of technique for preparing bromoethane, comprises the following steps:

[0094] 01. Feeding: pump ethanol and hydrobromic acid from the storage tank area into the closed intermediate tank of the workshop, and pump them into the tank 1 by metering;

[0095] 02. Reaction and primary distillation: pump quantitative 95% ethanol and quantitative 40% hydrobromic acid into box 1 respectively, stir for 0.5 hours, pump into the preheater, preheat to the set temperature, and enter the reactive distillation The tower reacts. The reactive distillation column is heated to 40°C for one rectification, the temperature of the tower bottom is 60°C, the temperature of the tower top is 40°C, and the reflux temperature is 15°C. The excess hydrobromic acid solution is pumped into the acid recovery tower to distill and recover hydrobromic acid, and the distillation waste liquid from the acid recovery tower is pumped into the waste liquid neutralization tank, and after adding metered l...

Embodiment 3

[0100] A kind of technique for preparing bromoethane, comprises the following steps:

[0101] 01. Feeding: pump ethanol and hydrobromic acid from the storage tank area into the closed intermediate tank of the workshop, and pump them into the tank 1 by metering;

[0102] 02. Reaction and primary distillation: pump quantitative 95% ethanol and quantitative 40% hydrobromic acid into box 1 respectively, stir for 0.5 hours, pump into the preheater, preheat to the set temperature, and enter the reactive distillation The tower reacts. The reactive distillation column is heated to 40°C for a rectification, the temperature of the tower bottom is 70°C, the temperature of the tower top is 45°C, and the reflux temperature is 15°C. The excess hydrobromic acid solution is pumped into the acid recovery tower to distill and recover hydrobromic acid, and the distillation waste liquid from the acid recovery tower is pumped into the waste liquid neutralization tank, and after adding metered liq...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com