A variable-wall-thickness sand mold structure design method for targeted control of casting microstructure and variable-wall-thickness sand mold structure

A technology of microstructure and structure design, applied in the field of sand casting, can solve the problems of shrinkage cavity casting microstructure, affecting the overall performance of castings, inconsistent heat dissipation, etc. Avoid the effects of manufacturing and machining processes

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

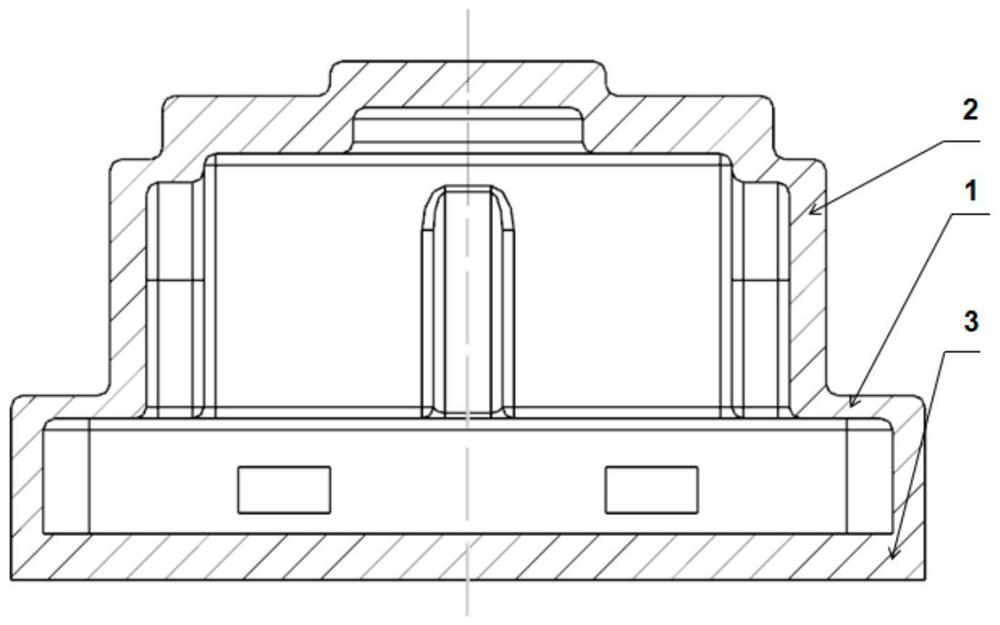

[0039] like figure 1 Shown is the variable thickness sand mold structure when casting the shell, including the inner working part 1 of the sand mold and the peripheral variable wall thickness part 2 of the sand mold; the inner working part 1 of the sand mold is a hollow shell, and the inner shape of the hollow shell is determined by the shell. The shape of the body part is determined; the peripheral variable wall thickness part 2 of the sand mold is determined by the heat dissipation of the part; the sand mold inner working part 1 is connected with the sand mold peripheral variable wall thickness part 2 as a whole.

[0040] The specific implementation process is: due to the uneven wall thickness of the casting and the uneven heat dissipation of each part, the exterior of the sand mold is designed as the peripheral variable wall thickness part 2 of the sand mold, such as figure 1 shown. In order to make the core meet the strength requirements during the casting process, the wa...

Embodiment 2

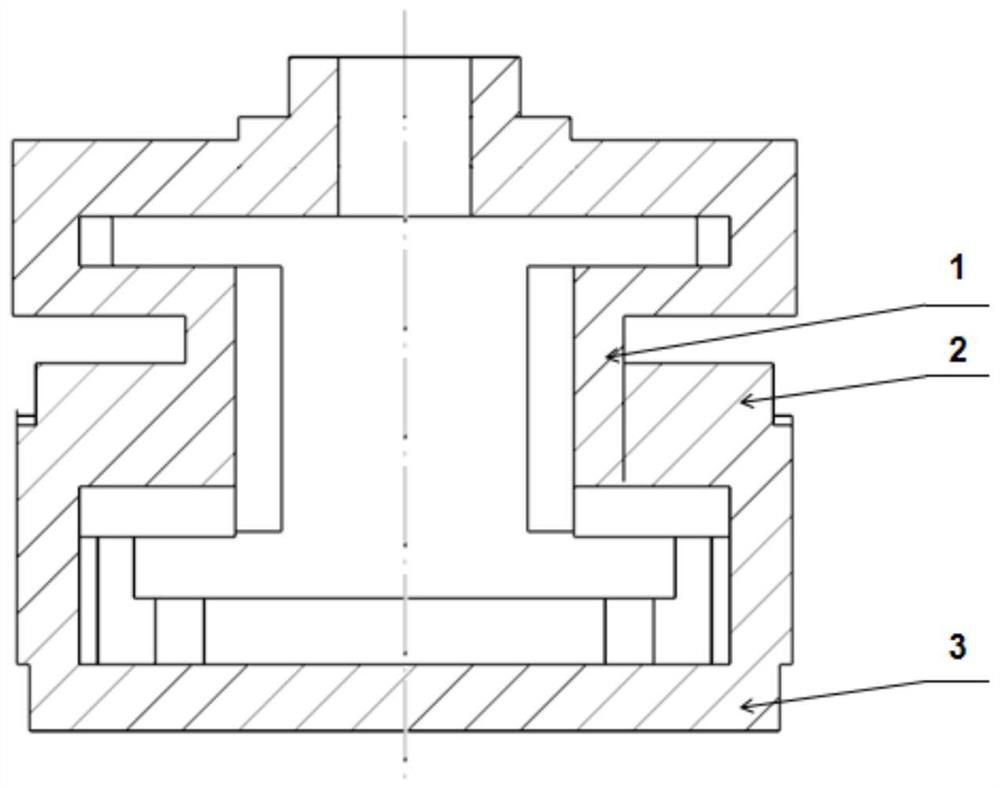

[0045] like figure 2 Shown is the variable-thickness sand mold structure when casting gearbox housing parts, including the inner working part 1 of the sand mold and the peripheral variable wall thickness part 2 of the sand mold; the inner working part 1 of the sand mold is a hollow shell; The internal shape is determined by the shape of the gearbox parts; the peripheral variable wall thickness part 2 of the sand mold is determined by the heat dissipation of the parts; the sand mold inner working part 1 and the sand mold peripheral variable wall thickness part 2 are connected as a whole.

[0046] The specific implementation process is that, in order to reduce the amount of sand used in making the sand mold, and at the same time to ensure that the parts dissipate evenly during the casting process, the exterior of the sand mold is designed as the outer part of the sand mold with variable wall thickness. figure 2 shown. In order to make the sand mold meet the strength requireme...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com