Narrow-gap laser-TIG electric arc composite welding device and welding method

A hybrid welding, narrow gap technology, applied in the field of welding manufacturing, can solve the problems of many welding passes, low TIG welding speed, low welding wire deposition efficiency, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0040]It should be noted that, in the case of no conflict, the embodiments of the present invention and the features in the embodiments can be combined with each other.

[0041] The present invention will be described in detail below with reference to the accompanying drawings and examples.

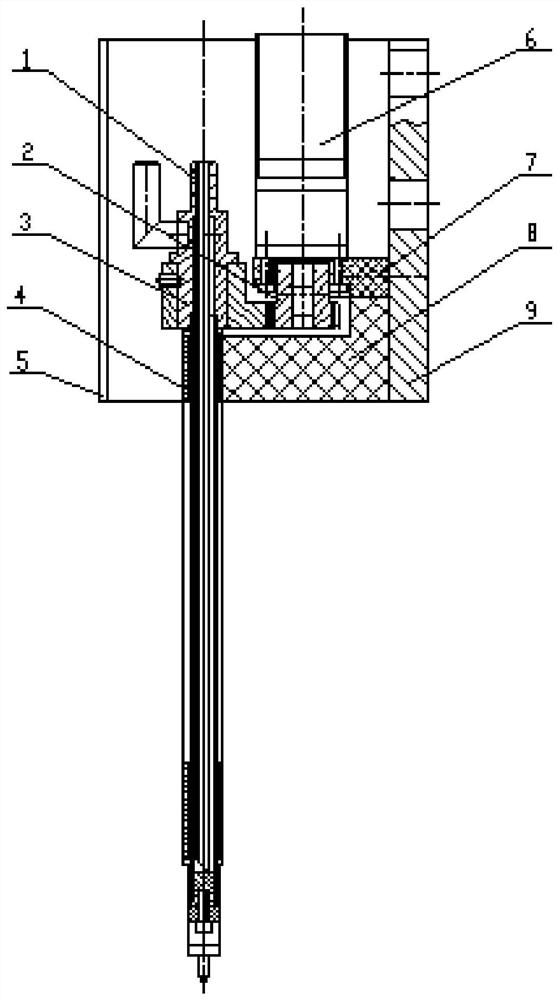

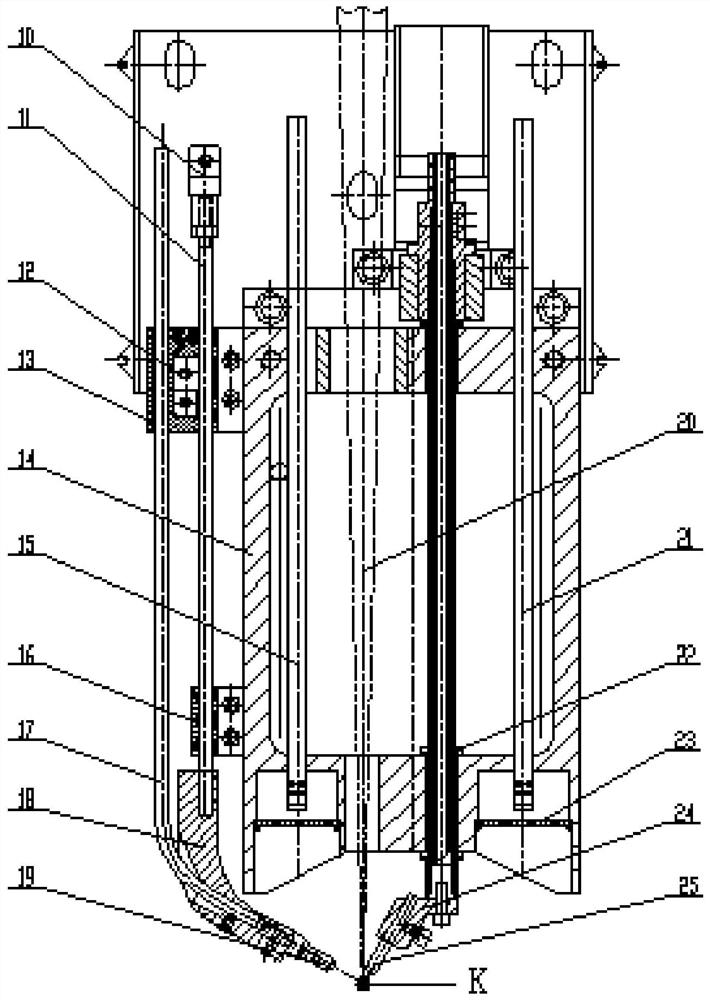

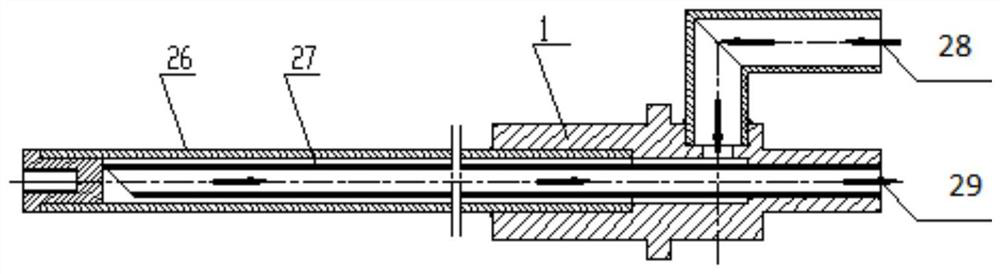

[0042] Such as Figure 1-Figure 3 As shown, a narrow gap laser-TIG arc hybrid welding device includes a welding torch body 14, a swing welding torch assembly A, a welding wire feeding heating assembly B and an air supply assembly, and the swing welding torch assembly includes a welding torch shaft 1, a stepping motor 6 , large gear 3, pinion 2, upper insulating sleeve 4, lower insulating sleeve 16, tungsten pole clip 24 and tungsten pole 25, the described stepper motor 6 is installed on the motor connecting seat 7, and the described pinion gear 2 is installed On the output shaft of the stepper motor 6, the large gear 3 is installed on the welding torch shaft 1, the pinion 2 and the large...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com