Triarylamine derivative and organic electroluminescent device thereof

A derivative, triarylamine technology, applied in the field of triarylamine derivatives and their organic electroluminescent devices, can solve the problems of poor film formation, low hole mobility, low luminous efficiency and low service life of light-emitting devices, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

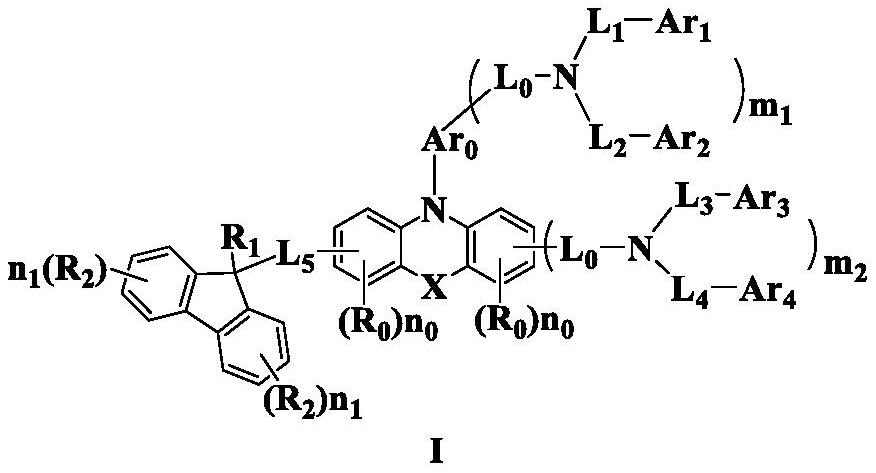

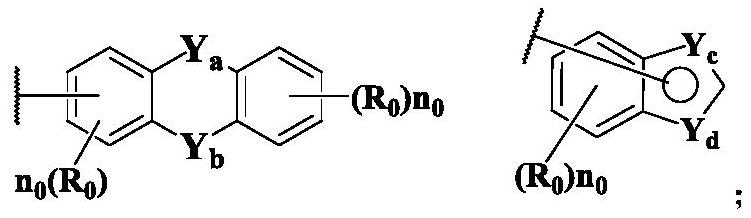

Method used

Image

Examples

preparation example Construction

[0151] Preparation and characterization of compounds

[0152] Description of raw materials, reagents, and characterization equipment:

Embodiment 48

[0249] [Example 48] Measurement of glass transition temperature

[0250] Test samples: Compound 1, Compound 3, Compound 14, Compound 16, Compound 17, Compound 28, Compound 39, Compound 48, Compound 59, Compound 64, Compound 72, Compound 78, Compound 90, Compound 103, Compound 115, Compound 137 , Compound 139, Compound 141, Compound 146, Compound 153, Compound 155, Compound 161, Compound 198, Compound 170, Compound 219, Compound 235, Compound 240, Compound 301, Compound 308, Compound 312, Compound 330, Compound 340, Compound 354, compound 361, compound 374, compound 386, compound 393, compound 399, compound 408, compound 415 and comparative compounds 1-2 were tested individually, and the mass of each sample was 5 mg.

[0251] Test instrument: DSC 25 Differential Scanning Calorimeter (TA Company, USA);

[0252] Test conditions: the test atmosphere is nitrogen, the flow rate of nitrogen is 50mL / min; the heating rate is 10°C / min, and the temperature range is 50-350°C. The glass ...

Embodiment 49

[0257] [Example 49] Test of material film-forming property:

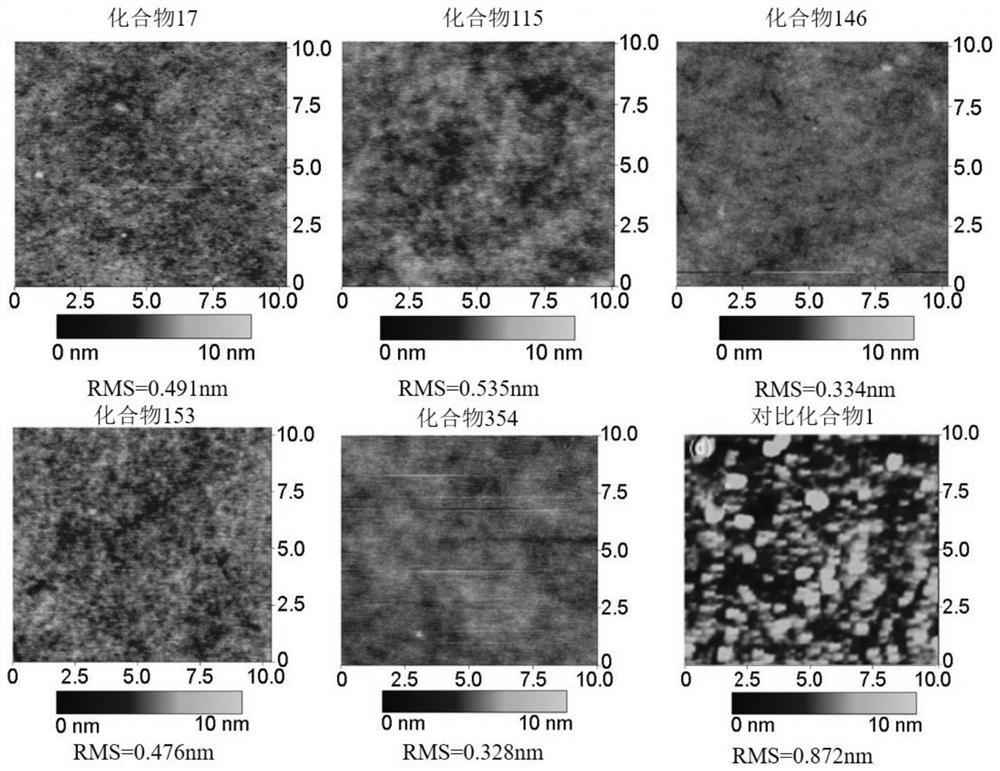

[0258] Compound 17 of the present invention, compound 115, compound 146, compound 153, compound 354 and comparative compound 1 were vapor-deposited on ITO glass substrates to prepare samples with a thickness of 10 nm. The compounds of the present invention 17 and 115 were characterized by atomic force microscopy. , compound 146, compound 153, compound 354 and the thin film morphology of compound 1. The film morphology of each sample is as follows: figure 1 The obtained surface roughness values are shown in Table 3:

[0259] Table 3: Surface Roughness (RMS) of Compounds

[0260] sample Surface Roughness (RMS) Compound 17 0.491 Compound 115 0.535 Compound 146 0.344 Compound 153 0.476 Compound 354 0.328 Comparative Compound 1 0.872

[0261] According to the results in Table 3, it can be seen that the compounds of the present invention have steric properties, the ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com