Fluoride-free water-repellent softening agent as well as preparation method and application thereof

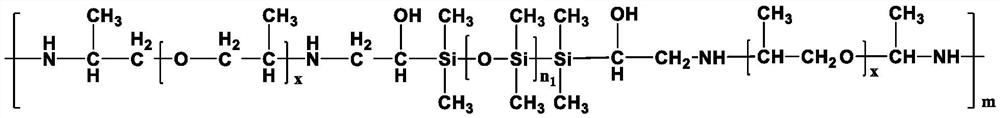

A fluorine-free water-repellent and softener technology, which is applied in the direction of improved hand-feeling fibers, textiles and papermaking, fiber treatment, etc., and can solve the problems of insufficient softness and smoothness of fabric touch

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

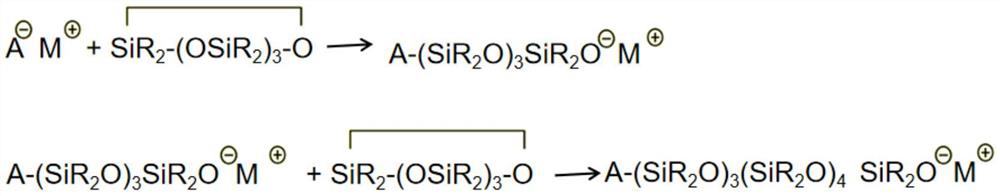

[0027] The application provides a method for preparing a fluorine-free water-repellent softener, comprising the following steps:

[0028] S1, mixing the silicone monomer, emulsifier and water to prepare the first emulsion;

[0029] S2, adding a catalyst to the first emulsion for reaction to obtain a first product, the first product includes polysiloxane whose terminal group is a hydroxyl group;

[0030] S3, remove the low boiler in the first product, obtain the second product, in the second product, octamethylcyclotetrasiloxane (D4), decamethylcyclopentasiloxane (D5), dodecamethylcyclopentasiloxane The content of hexasiloxane (D6) is lower than 1000ppm;

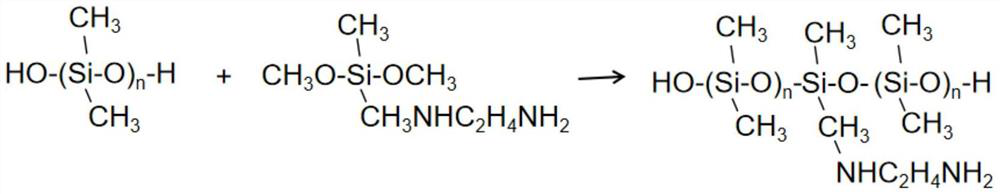

[0031] S4, adding an aminosilane coupling agent to the second product for reaction to obtain a third product, the third product includes polysiloxane whose end group is hydroxyl and whose chain segment contains amino groups.

[0032] Those skilled in the art can understand that the low boilers in the first product mainly re...

Embodiment 1

[0057] Step 1: Put 9g of fatty alcohol polyoxyethylene ether and 28g of silicone monomer (DMC) into the mixer, start stirring to mix evenly;

[0058] Step 2: Put the uniformly mixed material in step 1 into a high-pressure homogenizer, add 60g of water, and homogenize until the liquid turns bluish. After the particle size of the emulsion is tested to be less than 100nm, stop the homogenization;

[0059] Step 3: Put the homogenized liquid into a clean reactor, raise the temperature to 70°C, add 0.01g of sodium hydroxide, raise the temperature to 80°C, and keep it warm for 7 hours;

[0060] Step 4: Raise the temperature to 130°C, keep the vacuum at -0.1MPa for 10 hours, until the gas chromatography detects that the low ring body content is lower than 800ppm, and stop the vacuum;

[0061] Step 5: Add 2.5 g of γ-aminopropyltriethoxysilane and keep warm for 5 hours;

[0062] Step 6: Cool down to 45°C, add 0.5g of pH adjuster, stir evenly, and discharge.

Embodiment 2

[0064] Step 1: Put 8g of fatty alcohol polyoxyethylene ether and 29g of silicone monomer (DMC) into the mixer, start stirring to mix evenly;

[0065] Step 2: Put the uniformly mixed material in step 1 into a high-pressure homogenizer, add 59g of water, and homogenize until the liquid turns bluish. After the particle size of the emulsion is tested to be less than 100nm, stop the homogenization;

[0066] Step 3: Put the homogenized liquid into a clean reactor, raise the temperature to 70°C, add 0.01g of sodium hydroxide, raise the temperature to 90°C, and keep it warm for 8 hours;

[0067] Step 4: Raise the temperature to 150°C, keep the vacuum at -0.08MPa for 12 hours, until the gas chromatography detects that the low ring body content is lower than 800ppm, and stop the vacuum;

[0068] Step 5: Add 3 g of γ-aminopropyltrimethoxysilane and keep warm for 5-6 hours;

[0069] Step 6: Cool down to 45°C, add 0.5g of pH adjuster, stir evenly, and discharge.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com