Method for detecting residual content of ethylenediamine tetraacetic acid disodium salt in hyaluronic acid

A technology of sodium hyaluronate and hyaluronic acid, applied in measuring devices, instruments, scientific instruments, etc., can solve problems such as lack of detection

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

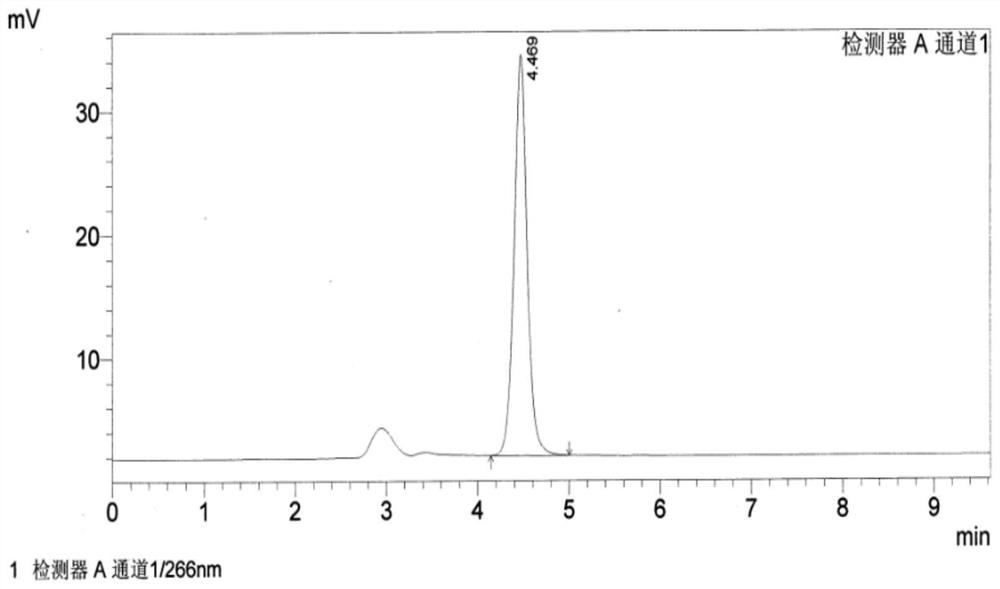

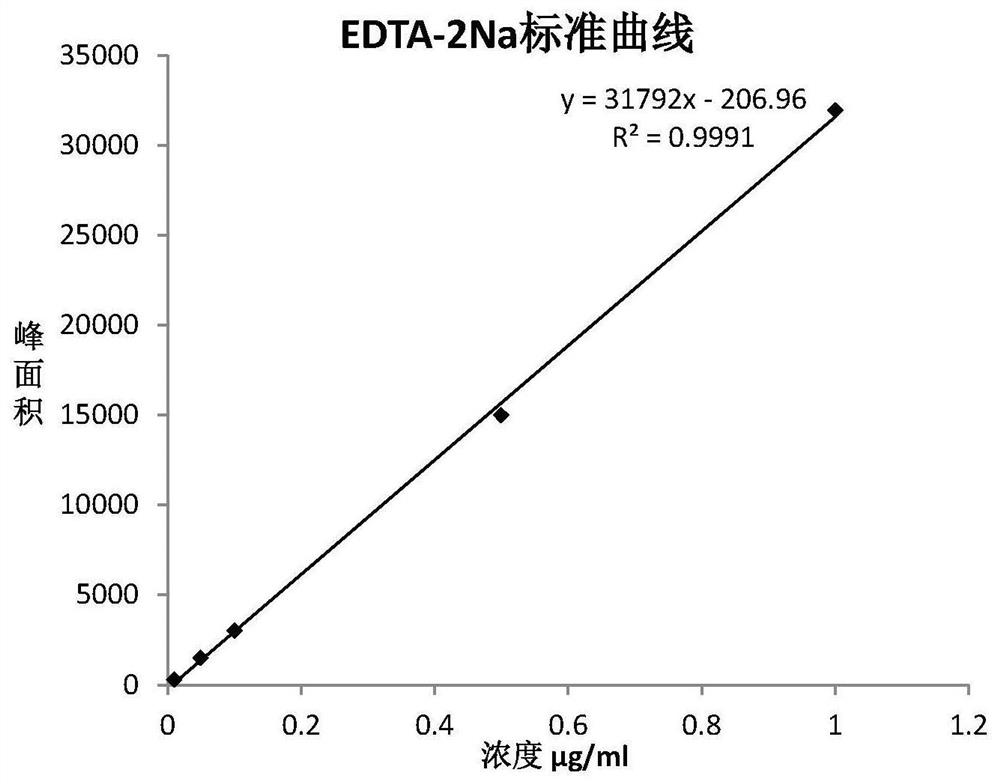

[0029] Example 1 Content detection of EDTA-2Na in sodium hyaluronate samples

[0030] (1) EDTA-2Na stock solution: Accurately weigh C 10 h 14 N 2 Na 2 o 8 2H 2 O 110.8 mg, put in a 100.0mL volumetric flask, dissolve in water and set the volume to the mark to obtain 1.0mg / mL EDTA-2Na standard stock solution;

[0031] (2) Hyaluronidase solution derived from bovine testis: According to the potency marked in the enzyme manual, weigh an appropriate amount of enzyme, add water to dissolve, and prepare a 100IU / mL hyaluronidase solution.

[0032] (2) Ferric chloride solution: Weigh 1.35 g of ferric chloride, add 30.0 mL of glacial acetic acid to dissolve, and dilute to 100 mL with water to obtain a 0.05 mol / L ferric chloride solution;

[0033] (3) Test solution: Accurately weigh 0.25 g of sodium hyaluronate (average molecular weight 1510 KDa, purity 99.2%), put it in a 150 mL iodine bottle, add 50.0 mL of hyaluronidase solution from bovine testis (enzyme effect price 5000IU), p...

Embodiment 2

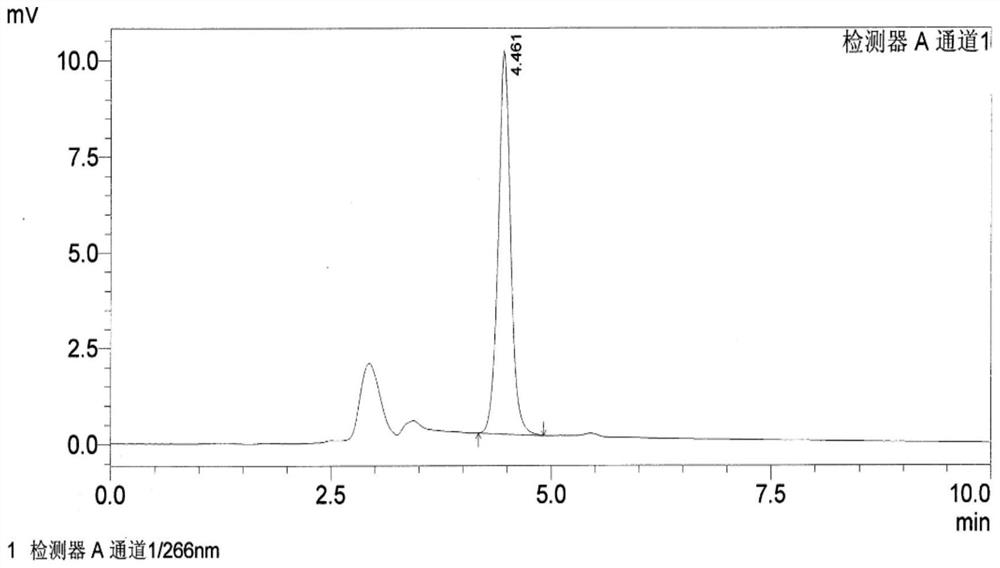

[0051] Example 2 Content detection of EDTA-2Na in sodium hyaluronate samples

[0052] (1) EDTA-2Na stock solution: Accurately weigh C 10 h 14 N 2 Na 2 o 8 2H 2 O 110.8 mg, put in a 100.0mL volumetric flask, dissolve in water and set the volume to the mark to obtain 1mg / mL EDTA-2Na standard stock solution;

[0053] (2) Recombinant leech hyaluronidase solution: According to the potency marked in the instructions, weigh an appropriate amount of enzyme, add water to dissolve, and prepare a 200IU / mL hyaluronidase solution.

[0054] (3) Ferric chloride solution: Weigh 1.35 g of ferric chloride, add 30 mL of glacial acetic acid to dissolve, and dilute to 100 mL with water to obtain 0.05 mol / L ferric chloride solution;

[0055] (4) Test solution: Accurately weigh 0.25g of sodium hyaluronate (average molecular weight 2005KDa, purity 101.9%) for test, put it in a 150mL iodine bottle, add 50mL of recombinant leech hyaluronidase solution (enzyme titer 10000IU) , adjust the pH of th...

PUM

| Property | Measurement | Unit |

|---|---|---|

| molecular weight | aaaaa | aaaaa |

| wavelength | aaaaa | aaaaa |

| molecular weight | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com