Enameled wire for an oil-cooled motor of new energy automobile and production and processing technology thereof

A new energy vehicle and processing technology, applied in the field of enameled wire, can solve problems such as complex processing deformation, loss of insulation, and hindering the development of new energy vehicles

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

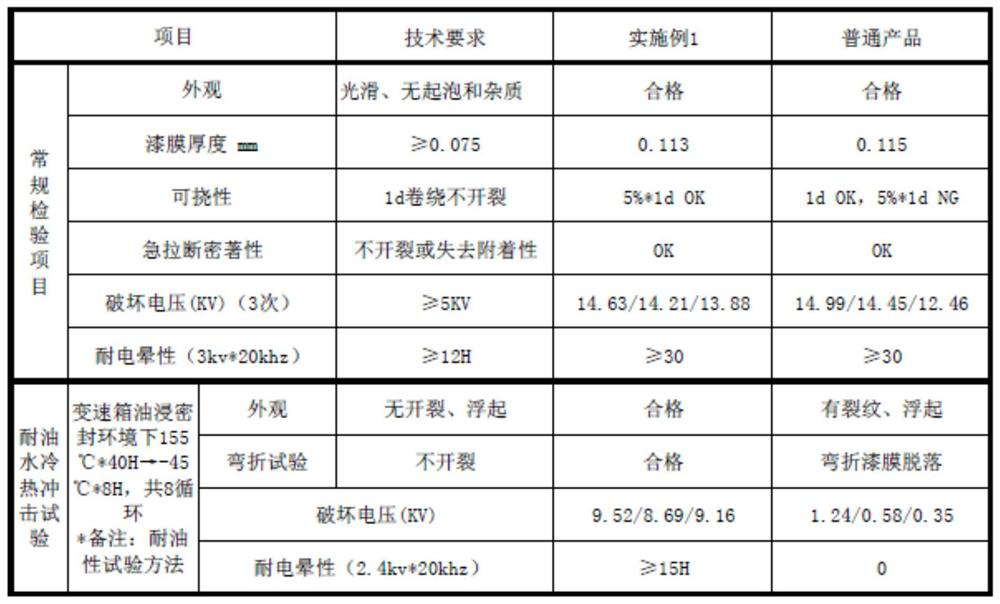

Embodiment 1

[0035] An enameled wire for an oil-cooled motor of a new energy vehicle, including a copper conductor, a primer layer, an intermediate paint layer and a top coat layer, the primer layer is made of high-adhesion polyamide-imide paint, and the middle paint layer is made of corona-resistant polyamide Imine paint, oil-resistant and hydrolysis-resistant polyamide-imide paint is used for the top coat layer, the paint film thickness of the primer layer accounts for 10% of the total paint film thickness, the intermediate layer accounts for 70% of the total paint film thickness, and the top coat Layers account for 20% of the total paint film thickness;

[0036] The total paint film thickness refers to the sum of the paint film thickness of the primer layer, intermediate paint layer and top coat layer;

[0037] The components of the high-adhesion polyamide-imide paint are as follows by weight percentage: polyamide-imide resin 28%, N-methylpyrrolidone 54%, N, N-dimethylformamide 18%;

...

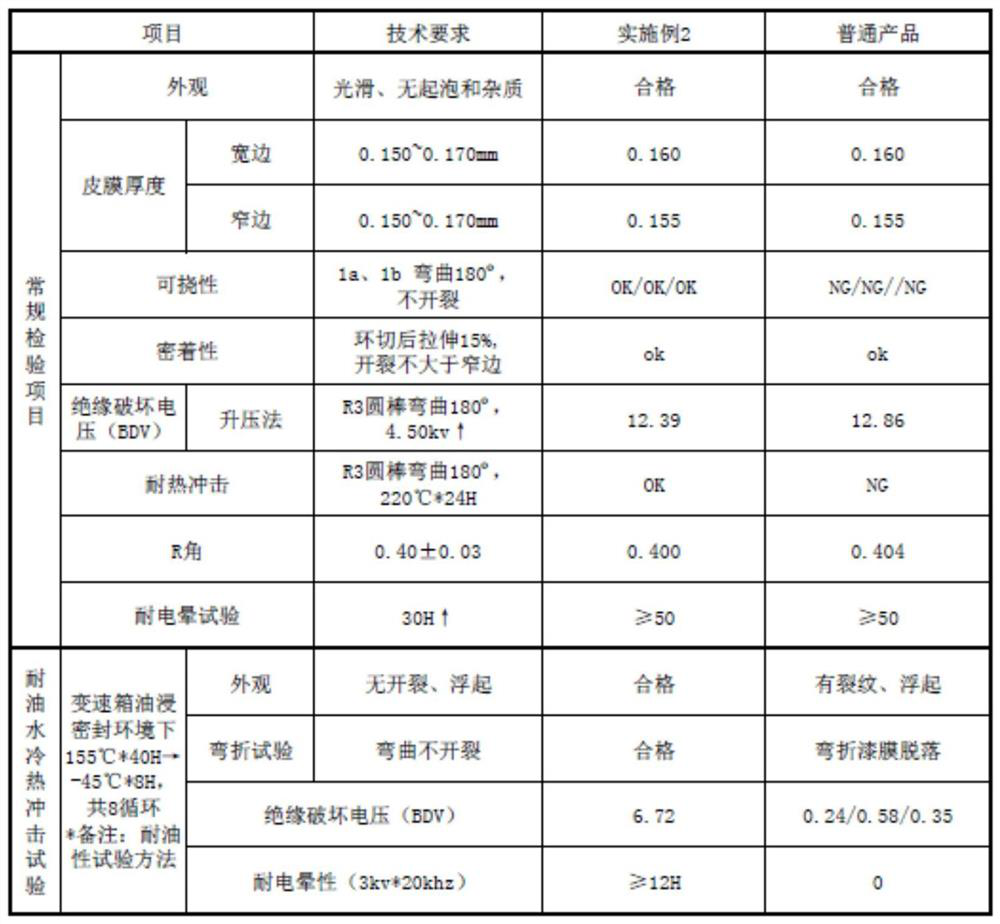

Embodiment 2

[0051] An enameled wire for an oil-cooled motor of a new energy vehicle, including a copper conductor, a primer layer, an intermediate paint layer and a top coat layer, the primer layer is made of high-adhesion polyamide-imide paint, and the middle paint layer is made of corona-resistant polyamide Imine paint, oil-resistant and hydrolysis-resistant polyamide-imide paint is used for the top coat layer, the paint film thickness of the primer layer accounts for 10% of the total paint film thickness, the intermediate layer accounts for 70% of the total paint film thickness, and the top coat Layers account for 20% of the total paint film thickness;

[0052] The total paint film thickness refers to the sum of the paint film thickness of the primer, intermediate paint and top coat;

[0053] The components of the high-adhesion polyamide-imide paint are as follows by weight percentage: polyamide-imide resin 25%, N-methylpyrrolidone 54%, N, N-dimethylformamide 21%;

[0054] The compone...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Oxygen content | aaaaa | aaaaa |

| Oxygen content | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com