Bimetal fluoride, preparation method thereof and application of bimetal fluoride in lithium-free positive electrode

A fluoride and bimetal technology, applied in the field of metal fluoride preparation, can solve the problems of cumbersome reaction steps and the like

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0039] The invention provides a method for preparing a double metal fluoride, which adopts a precursor reaction product fluorination process, comprising the following steps:

[0040] S1, placing the transition metal-based organometallic framework material and the transition metal nitrate in a molar ratio of (1-4):1 in a hydrothermal kettle, the hydrothermal solvent being water, and performing the first hydrothermal synthesis reaction;

[0041] S2, after the first hydrothermal synthesis reaction, cooling and taking out the reaction product, after centrifugal drying, dissolving the reaction product in aqueous hydrofluoric acid solution, stirring and heating to prepare a bimetallic fluoride;

[0042] The transition metal species in the transition metal-based organometallic framework material is different from the transition metal species in the transition metal nitrate.

[0043] Further, in the first hydrothermal synthesis reaction described in step S1, the hydrothermal temperatu...

Embodiment 1

[0058] Embodiment 1 provides a kind of preparation method of cobalt-nickel double metal fluoride, adopts precursor reaction product fluorination process, comprises the following steps:

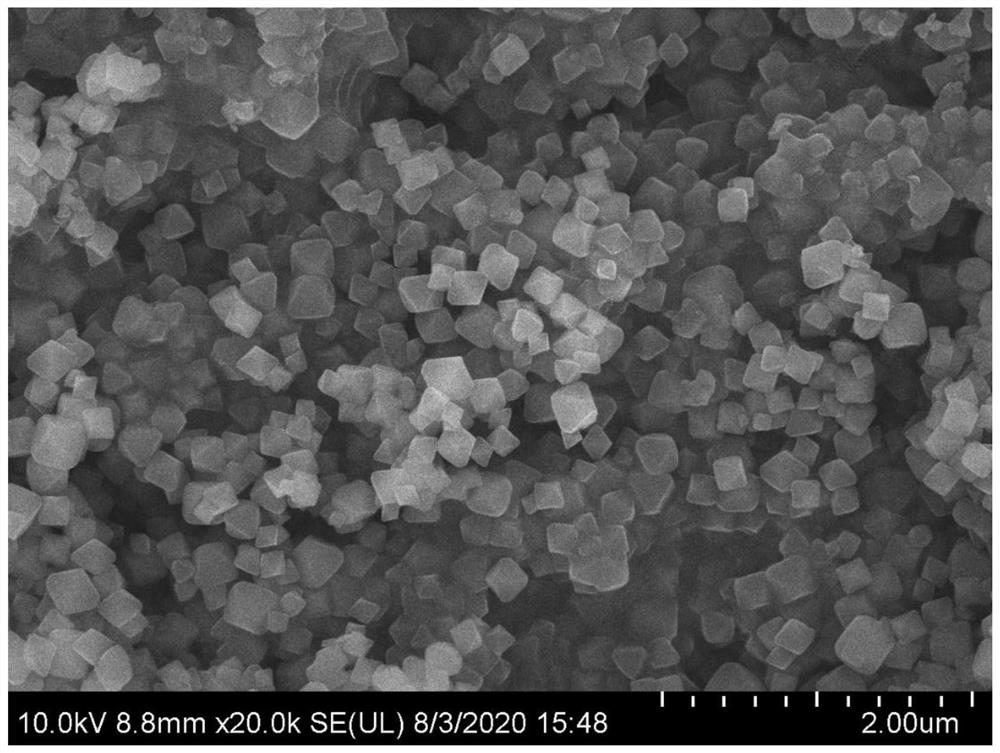

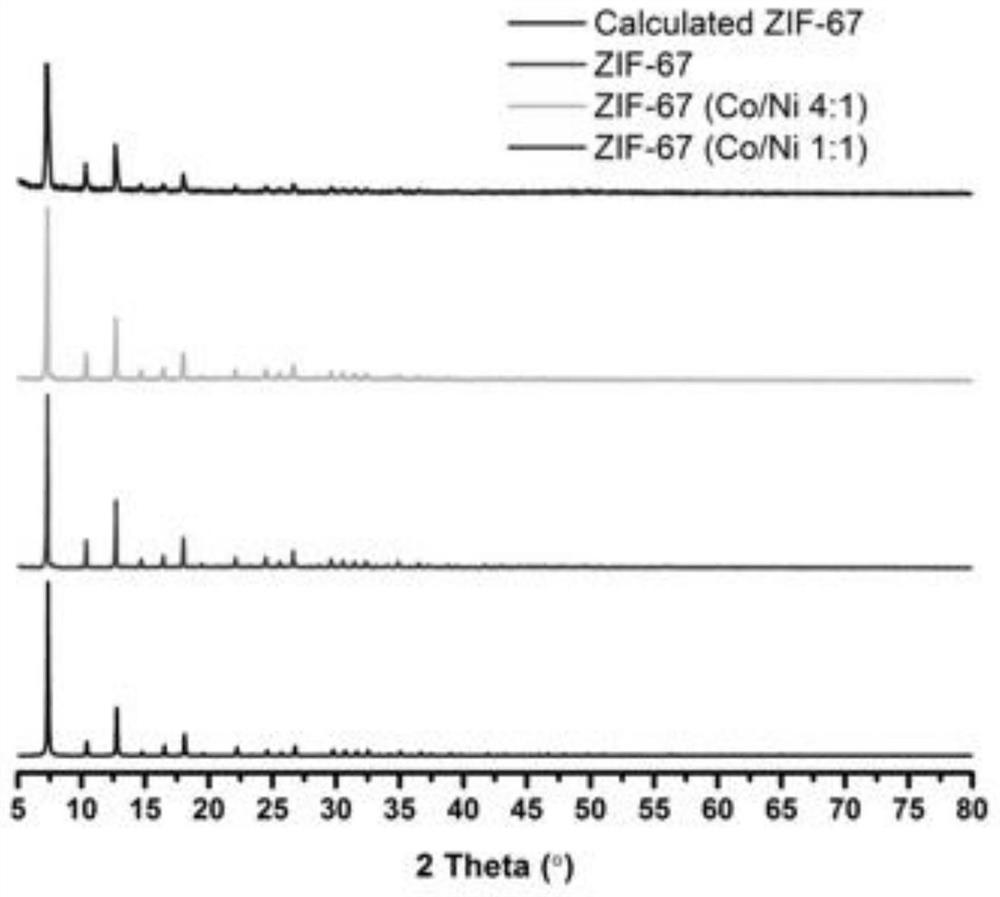

[0059] S1, the transition metal-based organometallic framework material ZIF-67 (such as figure 1 Shown) and transition metal nitrate-nickel nitrate are placed in a 200mL hydrothermal kettle at a molar ratio of 4:1, the hydrothermal solvent is water, the hydrothermal temperature is 180°C, and the time is 4h, the first hydrothermal synthesis reaction;

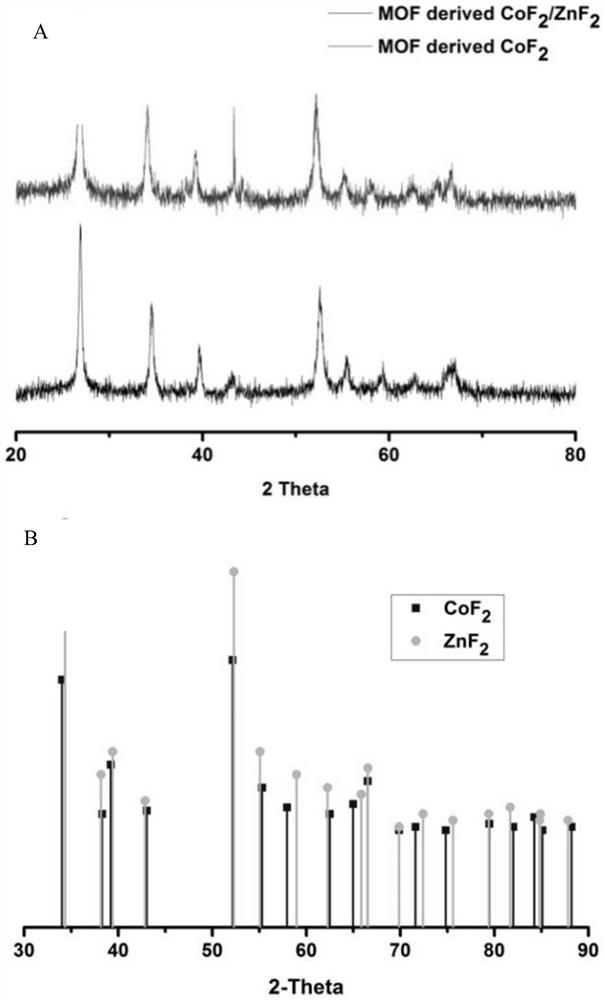

[0060] S2, after the first hydrothermal synthesis reaction is finished, cool down and take out the reaction product, after centrifugal drying, dissolve the reaction product in an aqueous solution of hydrofluoric acid (in the aqueous solution of hydrofluoric acid, the volume ratio of hydrofluoric acid to water is 1 : 8), heat treatment with stirring, the temperature of stirring and heating is 160° C., and the time of stirring and heating is 4 hou...

Embodiment 2

[0062] Embodiment 2 provides a kind of preparation method of cobalt-nickel double metal fluoride, adopts precursor reaction product fluorination process, comprises the following steps:

[0063] S1, put transition metal-based organometallic framework material ZIF-67 and transition metal nitrate-nickel nitrate in a molar ratio of 1:1 in a 200mL hydrothermal kettle, the hydrothermal solvent is water, and the hydrothermal temperature is 180°C , the time is 4h, carry out the first hydrothermal synthesis reaction;

[0064] S2, after the first hydrothermal synthesis reaction is finished, cool down and take out the reaction product, after centrifugal drying, dissolve the reaction product in an aqueous solution of hydrofluoric acid (in the aqueous solution of hydrofluoric acid, the volume ratio of hydrofluoric acid to water is 1 : 8), stirring and heating treatment, the stirring and heating temperature is 160 ° C, the stirring and heating time is 4h, and the cobalt-nickel bimetallic fl...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com