3D printing bio-ink capable of constructing multi-level bionic pore structure, preparation method of 3D printing bio-ink and printing method

A 3D printing and bio-ink technology, applied in tissue regeneration, prosthesis, additive processing, etc., can solve the problems of limiting cell proliferation and stretching, achieve good bone repair effect, promote bone repair and reconstruction, and promote bone repair and reconstruction effects Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0043] (1) Bone defect modeling

[0044] Taking the 1cm-long segmental defect of the right femur in rabbits as an example, CT scans were performed on the full length of both femurs, and the obtained data were imported into Mimics software, a new Mask was created, and the threshold range was set to 150-1000HU to obtain bone models on both sides Data; subtract the bone defect site from the contralateral healthy bone corresponding to the bone defect site by Boolean operations to obtain the data of the bone defect site, and calculate the porosity and nutrients in the compact bone area, cancellous bone area, and cancellous bone Pore area distribution; model based on the above information to obtain the model data of the target bone defect, add support structure data and adjust and determine the amount of each component in the 3D printing ink based on the data; finally export the required target bone defect in an STL format file 3D digital model of the bracket.

[0045] (2) 3D pri...

Embodiment 2

[0055] Bone defect modeling, preparation of methacrylic anhydride gelatin solid, and post-printing treatment are the same as in Example 1. The difference is that different bio-ink configuration methods and printing parameters are used.

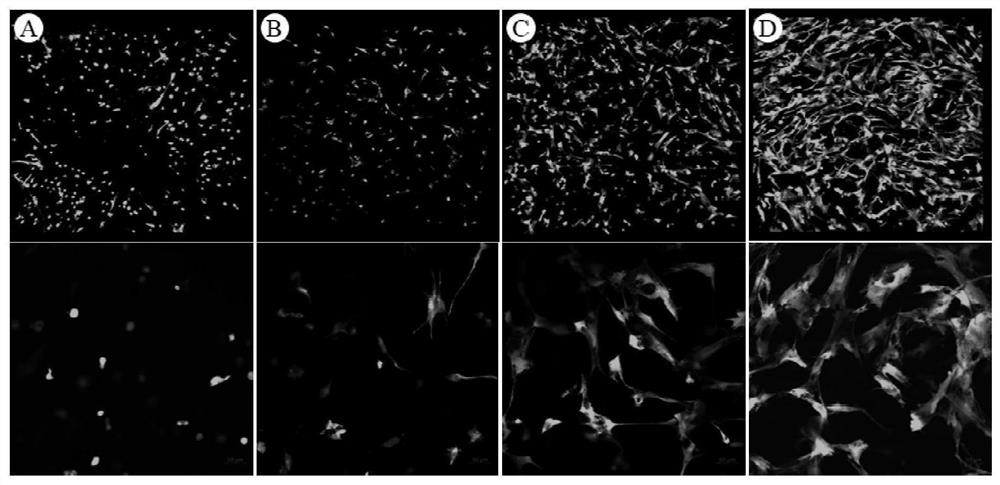

[0056] The bio-ink configuration is specifically to digest the bone marrow mesenchymal stem cells into a suspension and count them, take 1 million bone marrow mesenchymal stem cells and centrifuge them, blow and beat the centrifuged cells with 0.5ml of sterilized hydrogel solution, and resuspend them It is a cell suspension to obtain a cell-loaded hydrogel solution; then take 0.015g tricalcium phosphate and add it to the cell-loaded hydrogel solution and mix evenly to obtain a cell-loaded and 1.5wt% inorganic osteogenic active ingredient (inorganic growth factor) 0.5ml sterilized polyethylene oxide solution was added to the hydrogel solution containing cells and inorganic growth factors and mixed evenly to obtain a 3D printing bioink with a vo...

Embodiment 3

[0060] Bone defect modeling, preparation of methacrylic anhydride gelatin solid, and post-printing treatment are the same as in Example 1. The difference is that different bio-ink configuration methods and printing parameters are used.

[0061] The bio-ink configuration is specifically to digest the bone marrow mesenchymal stem cells into a suspension and count them, take 10 million bone marrow mesenchymal stem cells and centrifuge them, blow and beat the centrifuged cells with 0.75ml of sterilized hydrogel solution, and resuspend them It is a cell suspension to obtain a cell-loaded hydrogel solution; then take 0.005g tetracalcium phosphate and add the cell-loaded hydrogel solution and mix evenly to obtain a cell-loaded and 0.5wt% inorganic growth factor hydrogel solution; Add 0.25ml of sterilized polyethylene oxide solution to the hydrogel solution loaded with cells and inorganic growth factors and mix evenly to obtain a 3D printed bio-ink with a volume ratio of 3:1; immediat...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Wire diameter | aaaaa | aaaaa |

| Diameter | aaaaa | aaaaa |

| Wire diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com