Preparation method of sheet-shaped rubber antiskid belt for tire

An anti-skid belt and rubber technology, which is applied in the field of tire products, can solve the problems of plastic anti-skid belts being brittle and hard, the contact area of the anti-skid belt is small, and the anti-skid effect is not good. Embrittlement temperature, good anti-skid effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

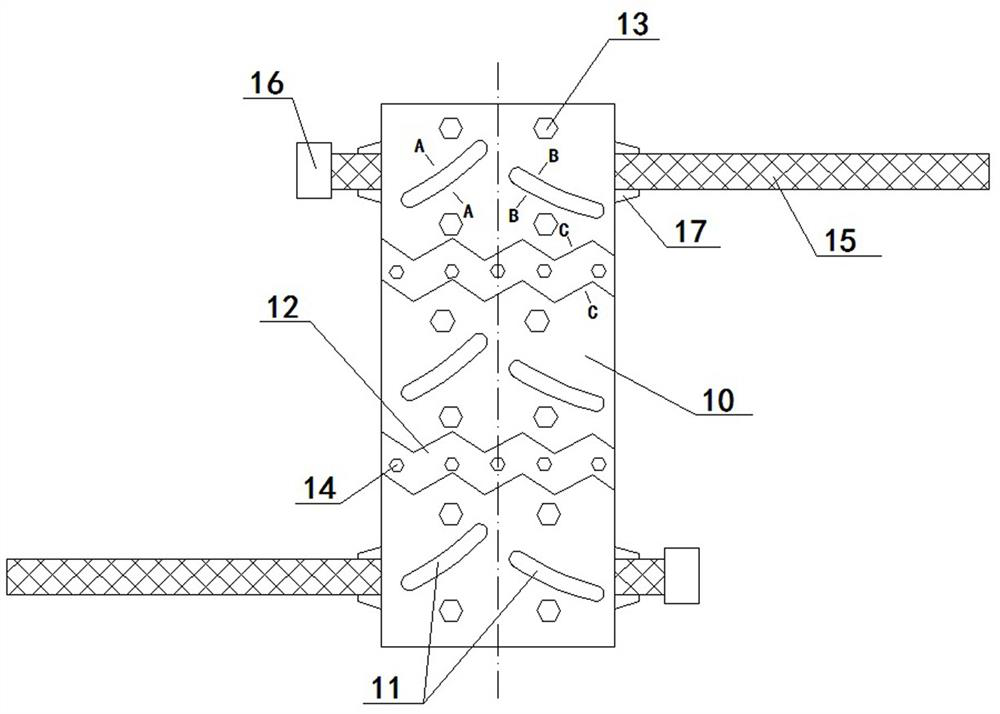

Image

Examples

Embodiment 2

[0053] 40 parts of natural rubber / butadiene rubber blend, 25 parts of solution polystyrene butadiene rubber, 5 parts of methylphenyl vinyl silicone rubber (7-10%), 30 parts of brominated isobutylene-p-methylstyrene rubber, 55 parts of carbon black; 20 parts of fumed white carbon black; 0.3 part of sulfur, 3.5 parts of accelerator; 5.0 parts of total consumption of antioxidant 3100, antioxidant TMQ and antioxidant 2246, 0.8 part of dicumyl peroxide; 1.0 parts of oxide co-crosslinking agent high vinyl 1,2 polybutadiene resin (liquid), 10 parts of zinc oxide; 3 parts of stearic acid, 1.5 parts of softening plasticizer and anti-scorch agent in total. The first-stage vulcanization is vulcanized by injection press, the vulcanization temperature is 160, the pressure of the injection press is 120MPa, and the vulcanization time is determined according to the thickness of the sheet rubber anti-skid belt; the second-stage vulcanization is vulcanized by oven, the temperature is 155°C, and ...

Embodiment 3

[0055] 50 parts of natural rubber / butadiene rubber blend, 20 parts of solution-polymerized styrene-butadiene rubber, 5 parts of methylphenyl vinyl silicone rubber (7-10%), 25 parts of brominated isobutylene-p-methylstyrene rubber, 60 parts of carbon black; 30 parts of fumed white carbon black; 0.5 part of sulfur, 4.0 parts of accelerator; 5.0 parts of the total consumption of anti-aging agent 3100, anti-aging agent TMQ and anti-aging agent 2246, 1.0 part of dicumyl peroxide; 1.1 parts of oxide co-crosslinking agent high vinyl 1,2 polybutadiene resin (liquid), 12 parts of zinc oxide; 4 parts of stearic acid, 1.5 parts of softening plasticizer and anti-scorch agent. The first-stage vulcanization is vulcanized by injection press, the vulcanization temperature is 162°C, the pressure of the injection press is 135MPa, and the vulcanization time depends on the thickness of the sheet rubber anti-skid belt; the second-stage vulcanization is mainly peroxide vulcanization, and the tempera...

Embodiment 4

[0057] 50 parts of natural rubber / butadiene rubber blend, 15 parts of solution-polymerized styrene-butadiene rubber, 7 parts of methylphenyl vinyl silicone rubber (7-10%), 28 parts of brominated isobutylene-p-methylstyrene rubber, 65 parts of carbon black; 40 parts of fumed white carbon black; 0.6 parts of sulfur, 5.5 parts of various accelerators; 5.0 parts of anti-aging agent 3100, anti-aging agent TMQ and anti-aging agent 2246, 1.2 parts of dicumyl peroxide 1.2 parts peroxide co-crosslinking agent high vinyl 1,2 polybutadiene resin (liquid), 15 parts zinc oxide; 5 parts stearic acid, the total amount of softening plasticizer and anti-scorch agent 1.5 share. The first-stage vulcanization is vulcanized by injection press, the vulcanization temperature is 165°C, the pressure of the injection press is 150MPa, and the vulcanization time depends on the thickness of the sheet rubber anti-skid belt; the second-stage vulcanization is mainly peroxide vulcanization, and the temperatur...

PUM

| Property | Measurement | Unit |

|---|---|---|

| depth | aaaaa | aaaaa |

| depth | aaaaa | aaaaa |

| depth | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com