Asphalt road interlayer adhesive and preparation method thereof

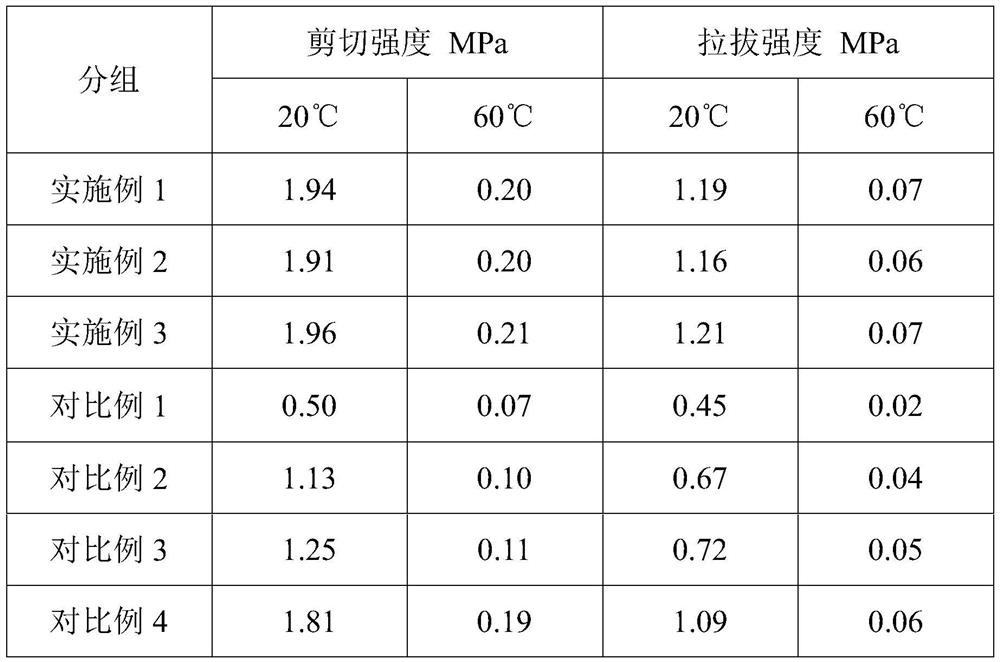

An adhesive and road technology, applied in the direction of adhesive types, polyurea/polyurethane adhesives, polymer adhesive additives, etc. Low stability and other problems, to achieve the effect of promoting repair, improving waterproof performance, improving shear strength and bond strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0028] A preparation method for an asphalt road interlayer adhesive, comprising the steps of:

[0029] Cyclodextrin polyrotaxanes were prepared with reference to the method in the literature Liu Y, Yang Y W, Chen Y, Zou HX.Polyrotaxane with Cyclodextrinsas Stoppers and Its Assembly Behavior[J].Macromolecules,2005,38(13):5838-5840;

[0030] Add oil-based asphalt repair agent to styrene maleic anhydride (surfactant) aqueous solution, disperse and emulsify at a high speed for 10 minutes and mix to obtain an emulsion; slowly add methyl etherified hexamethylolmelamine prepolymer solution dropwise to the emulsion to Stir and mix at a speed of 500r / min. After the dropwise addition, raise the temperature to 65°C, then adjust the pH to 5 with acetic acid aqueous solution, then raise the temperature to 80°C, keep stirring and react for 2 hours, cool to room temperature, filter, wash, and dry to obtain self-healing Microcapsules, wherein the weight ratio of the methylated hexamethylolmel...

Embodiment 2

[0033] A preparation method for an asphalt road interlayer adhesive, comprising the steps of:

[0034] Cyclodextrin polyrotaxanes were prepared with reference to the method in the literature Liu Y, Yang Y W, Chen Y, Zou HX.Polyrotaxane with Cyclodextrinsas Stoppers and Its Assembly Behavior[J].Macromolecules,2005,38(13):5838-5840;

[0035] Add oil-based asphalt repair agent to styrene maleic anhydride (surfactant) aqueous solution, disperse and emulsify at a high speed for 10 minutes and mix to obtain an emulsion; slowly add methyl etherified hexamethylolmelamine prepolymer solution dropwise to the emulsion to Stir and mix at a speed of 500r / min. After the dropwise addition, raise the temperature to 65°C, then adjust the pH to 5 with acetic acid aqueous solution, then raise the temperature to 80°C, keep stirring and react for 2 hours, cool to room temperature, filter, wash, and dry to obtain self-healing Microcapsules, wherein the weight ratio of the methylated hexamethylolmel...

Embodiment 3

[0038] A preparation method for an asphalt road interlayer adhesive, comprising the steps of:

[0039]The cyclodextrin polyrotaxane was obtained by referring to the method in the literature Liu Y, Yang Y W, Chen Y, Zou HX.Polyrotaxane with Cyclodextrinsas Stoppers and Its Assembly Behavior[J].Macromolecules,2005,38(13):5838-5840;

[0040] Add oil-based asphalt repair agent to styrene maleic anhydride (surfactant) aqueous solution, disperse and emulsify at a high speed and mix for 10 minutes to obtain an emulsion; slowly add methyl etherified hexamethylolmelamine prepolymer solution dropwise to the emulsion to Stir and mix at a speed of 500r / min. After the dropwise addition, raise the temperature to 65°C, then adjust the pH to 5 with acetic acid aqueous solution, then raise the temperature to 80°C, keep stirring and react for 2 hours, cool to room temperature, filter, wash, and dry to obtain self-healing Microcapsules, wherein the weight ratio of the methylated hexamethylolmela...

PUM

| Property | Measurement | Unit |

|---|---|---|

| viscosity | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

| shear strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com