Bacillus polymyxa high-yield exopolysaccharide culture medium and application method thereof

A technology of Bacillus polymyxa and exopolysaccharide, which is applied in the field of microorganisms to achieve the effects of promoting secretion, shortening the period of fermentation, and improving the efficiency of exopolysaccharide

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0028] Medium sample 1: including seed medium and fermentation medium;

[0029] Seed medium (according to mass concentration): yeast powder 30g / L, glucose 25g / L, peptone 13g / L, potassium dihydrogen phosphate 4g / L, ammonium nitrate 1g / L, sodium chloride 0.08g / L, heptahydrate Magnesium sulfate 15g / L, ferric chloride 0.07g / L, the rest is water;

[0030] Fermentation medium (by mass concentration): sucrose 60g / L, fermentation regulator 0.55g / L, peptone 35g / L, yeast powder 40g / L, potassium dihydrogen phosphate 4g / L, magnesium sulfate heptahydrate 15g / L, Ammonium nitrate 1g / L, sodium chloride 0.08g / L, ammonium nitrate 1g / L, ferric chloride 0.07g / L, the rest is water;

[0031] The fermentation regulator is formed by mixing two components, A and B, wherein the component is palmitoyl tripeptide-1, component B is asiaticoside, and the mass ratio of components A and B is 3:2.

[0032] Comparative medium 1-1: the difference from medium sample 1 is that there is no fermentation regulator...

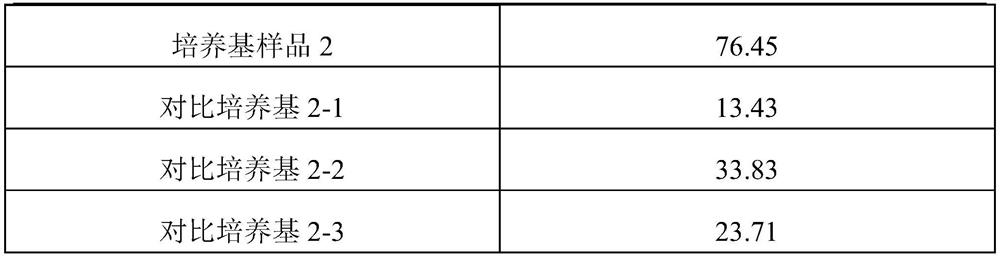

Embodiment 2

[0043] Medium sample 2: including seed medium and fermentation medium;

[0044] Seed medium (according to mass concentration): yeast powder 20g / L, glucose 30g / L, peptone 10g / L, potassium dihydrogen phosphate 0.1g / L, ammonium nitrate 0.2g / L, sodium chloride 0.05g / L, Magnesium sulfate heptahydrate 5g / L, ferric chloride 0.05g / L, the rest is water;

[0045] Fermentation medium (according to mass concentration): sucrose 50g / L, fermentation regulator 0.5g / L, peptone 20g / L, yeast powder 35g / L, potassium dihydrogen phosphate 0.5g / L, magnesium sulfate heptahydrate 5g / L , ammonium nitrate 0.2g / L, sodium chloride 0.05g / L, ammonium nitrate 0.2g / L, ferric chloride 0.05g / L, and the rest is water;

[0046] The fermentation regulator is formed by mixing two components, A and B, wherein component A is palmitoyl tripeptide-7, component B is selected from asiaticoside, and the mass ratio of components A and B is 4:1.

[0047] Comparative culture medium 2-1: different from culture medium sample...

Embodiment 3

[0059] Medium sample 3: including seed medium and fermentation medium;

[0060] Seed medium (according to mass concentration): yeast powder 40g / L, glucose 40g / L, peptone 15g / L, potassium dihydrogen phosphate 8g / L, ammonium nitrate 2g / L, sodium chloride 0.1g / L, heptahydrate Magnesium sulfate 10g / L, ferric chloride 0.1g / L, the rest is water;

[0061] Fermentation medium (by mass concentration): sucrose 80g / L, fermentation regulator 0.6g / L, peptone 45g / L, yeast powder 45g / L, potassium dihydrogen phosphate 10g / L, magnesium sulfate heptahydrate 10g / L, Ammonium nitrate 2g / L, sodium chloride 0.1g / L, ammonium nitrate 2g / L, ferric chloride 0.1g / L, the rest is water;

[0062] The fermentation regulator is a mixture of two components A and B, wherein component A is a mixture of palmitoyl tripeptide-1 and palmitoyl tripeptide-7, wherein palmitoyl tripeptide-1 and palmitoyl tripeptide- 7 The mass ratio is 1:1, component B is madecassoside, and the mass ratio of components A and B is 1:2....

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com