Bionic collagen membrane coated sheet and preparation method thereof

A biomimetic glue, membrane-encapsulated technology, applied in the field of cell or tissue culture materials, can solve the problems of complicated operation, low collagen coating rate, and high collagen concentration requirements, and achieve the effects of good activity, good cell affinity, and easy operation.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

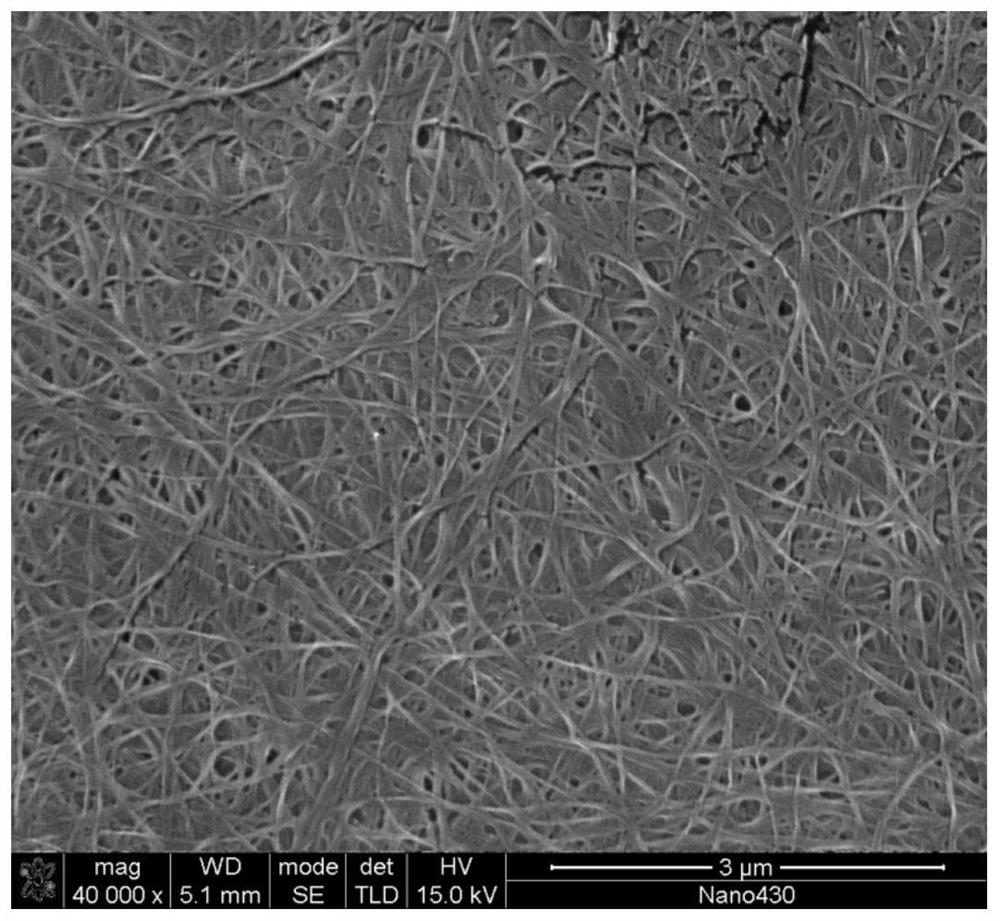

[0046] A method for bionic collagen film coating sheet, the steps are as follows:

[0047] (1) Type I collagen was added into 0.02M acetic acid solution to prepare a collagen acetic acid solution with a type I collagen concentration of 0.2 mg / ml.

[0048] (2) preparation of collagen reconstitution buffer; this buffer contains 270mM NaCl, 60mM HEPES, 60mM Na 2 HPO 4 .

[0049](3) Mix the collagen acetic acid solution described in step (1) and the collagen recombination buffer solution described in step (2) in a ratio of 1:1 to obtain a mixed solution, and use 1M NaOH to adjust the pH of the mixed solution to be neutral, Take 1ml of the pH-adjusted mixed solution and add it to a 12-well plate, vertically erect a polystyrene sheet in the well plate, cover the lid, and keep warm in an oven at 30 degrees Celsius for 1 hour.

[0050] (4) Open the lid of the 12-well plate containing recombinant collagen obtained in step (3), and bake in an oven at 30 degrees Celsius for 2 hours to...

Embodiment 2

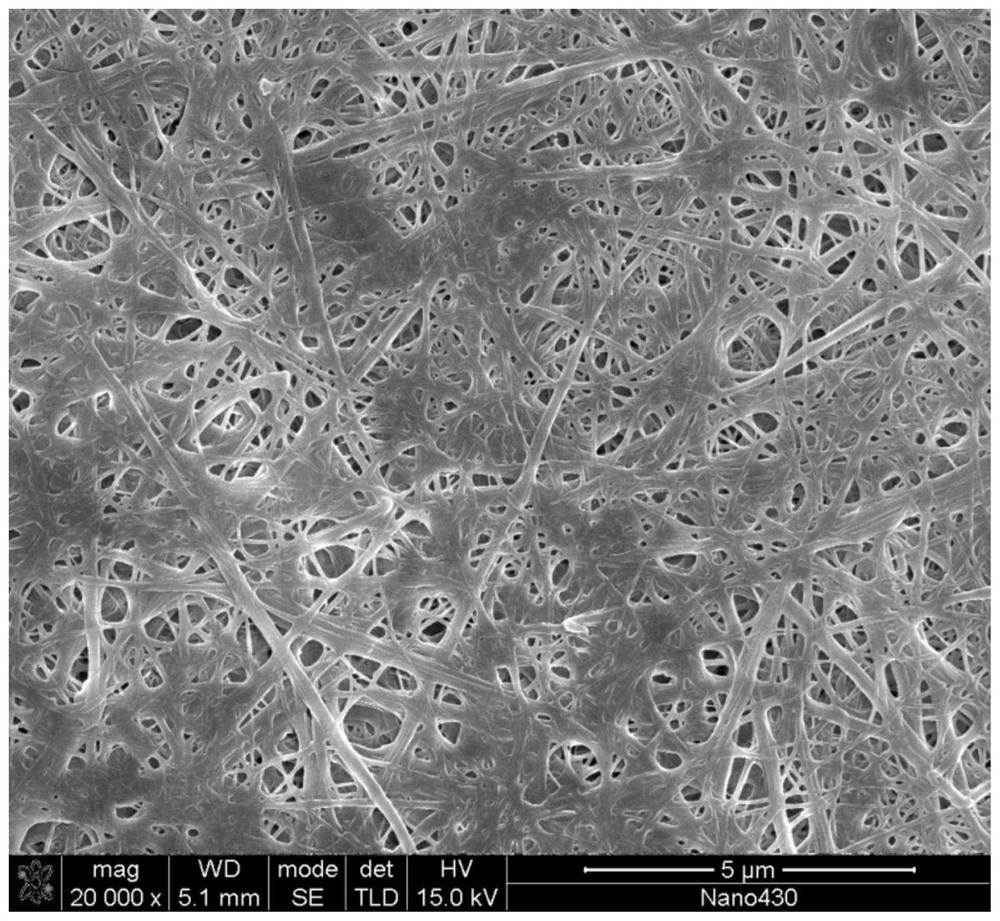

[0055] A method for bionic collagen film coating sheet, the steps are as follows:

[0056] (1) Type I collagen was added into 0.005M acetic acid solution to prepare a collagen acetic acid solution with a type I collagen concentration of 0.05 mg / ml.

[0057] (2) preparation of collagen reconstitution buffer; this buffer contains 270mM NaCl, 60mM HEPES, 60mM Na 2 HPO 4 .

[0058] (3) Mix the collagen acetic acid solution described in step (1) and the buffer solution described in step (2) in a ratio of 1:1 to obtain a mixed solution, use 1M NaOH to adjust the pH of the mixed solution to be neutral, take 1ml The pH-adjusted mixed solution was added to a 12-well plate, and a polyethylene sheet was vertically erected in the well plate, covered with a lid, and kept in an oven at 30 degrees Celsius for 2 hours.

[0059] (4) Open the lid of the 12-well plate containing recombinant collagen obtained in step (3), and bake in an oven at 30 degrees Celsius for 12 hours to obtain a biomi...

Embodiment 3

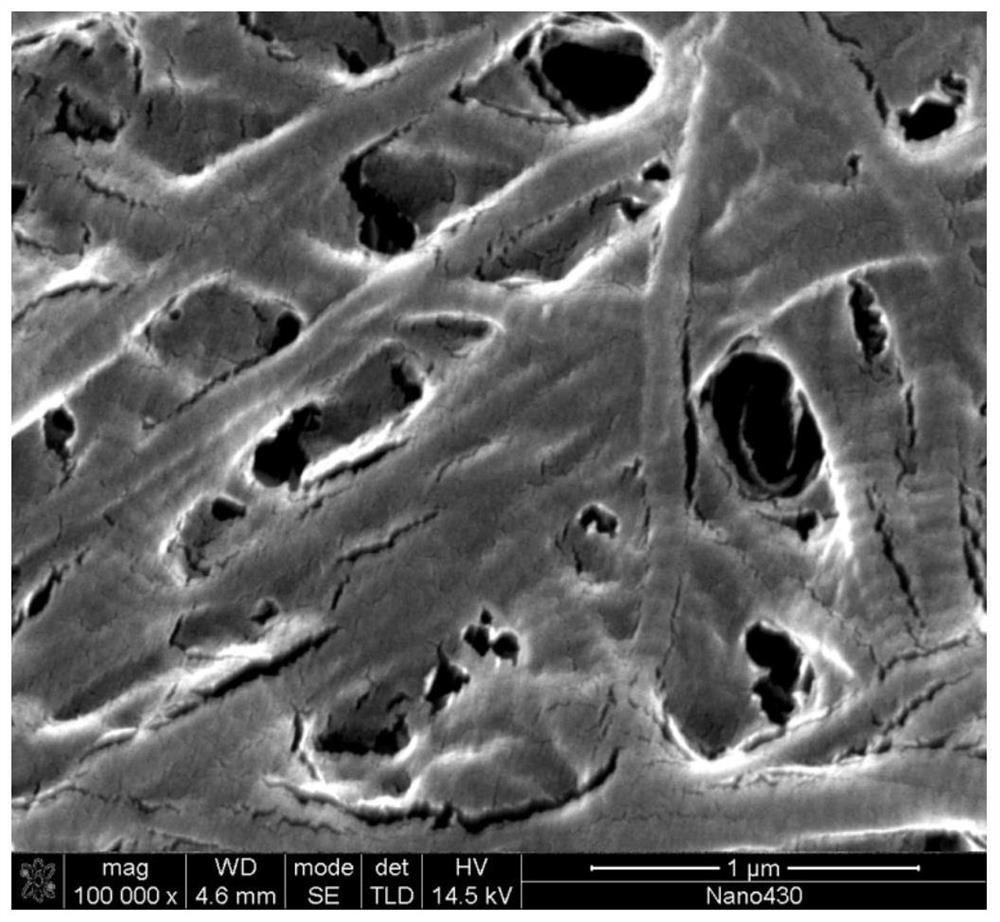

[0063] A method for bionic collagen film coating sheet, the steps are as follows:

[0064] (1) Type I collagen was added into 0.05M acetic acid solution to prepare a collagen acetic acid solution with a type I collagen concentration of 0.5 mg / ml.

[0065] (2) preparation of collagen recombination buffer; this buffer contains 540mM NaCl, 120mM HEPES, 120mM Na 2 HPO 4 .

[0066] (3) Mix the collagen acetic acid solution described in step (1) and the buffer solution described in step (2) uniformly in a ratio of 3:1 to obtain a mixed solution, use 1MNaOH to adjust the pH of the mixed solution to be neutral, take Add 1ml of the pH-adjusted mixed solution into a 12-well plate, place the silicon wafer vertically in the well plate, cover the lid, and keep the temperature in an oven at 30 degrees Celsius for 5 hours.

[0067] (4) Open the lid of the 12-well plate containing recombinant collagen obtained in step (3), and dry it in an oven at 35 degrees Celsius for 48 hours until the ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| concentration | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| depth | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com