Catalyst for electrocatalytic carbon dioxide reduction reaction as well as preparation method and application of catalyst

A carbon dioxide, electrocatalysis technology, applied in electrodes, electrolysis process, electrolysis components, etc., can solve the problems of serious side reactions, insufficient catalytic performance, low product selectivity, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0036]The present invention also provides a method for preparing a catalyst for the electrocatalytic carbon dioxide reduction reaction described in the above technical solution, comprising the following steps:

[0037] mixing sodium chloride, glucose, nickel acetate tetrahydrate, boric acid and water, and freeze-drying to obtain a precursor;

[0038] The precursor is carbonized and calcined in sequence to obtain the catalyst for the electrocatalytic carbon dioxide reduction reaction.

[0039] In the present invention, unless otherwise specified, the raw materials used in the present invention are preferably commercially available products.

[0040] In the invention, sodium chloride, glucose, nickel acetate tetrahydrate, boric acid and water are mixed and freeze-dried to obtain a precursor.

[0041] In the present invention, the mass ratio of the sodium chloride, glucose, nickel acetate tetrahydrate and boric acid is preferably 10000:750:12:(20-40), more preferably 10000:750:1...

Embodiment 1

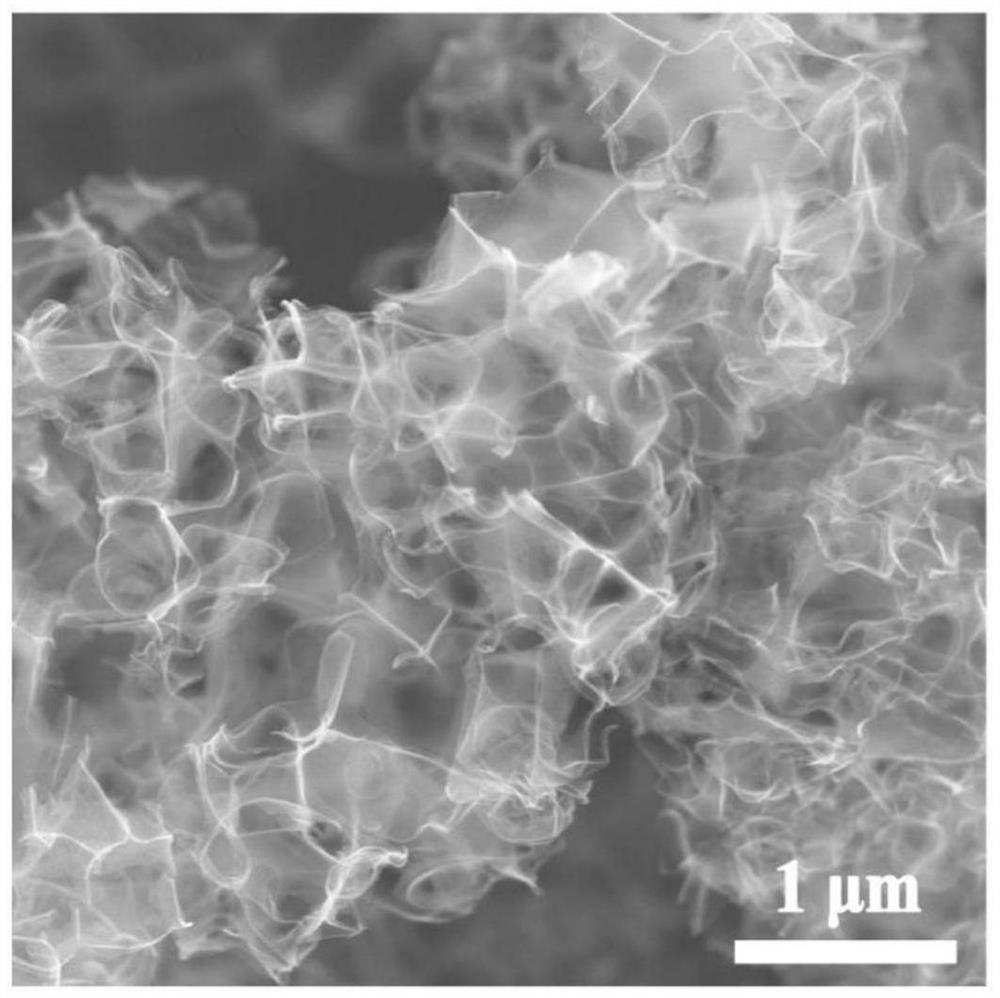

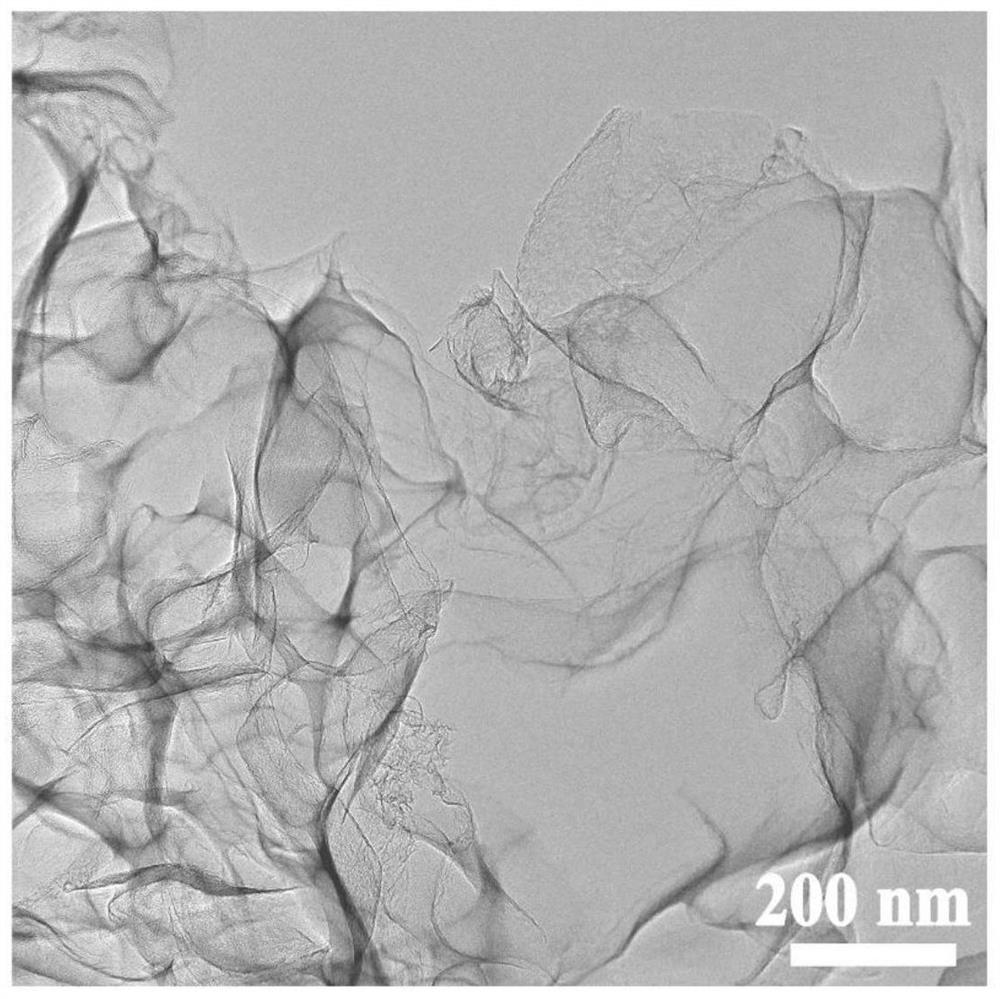

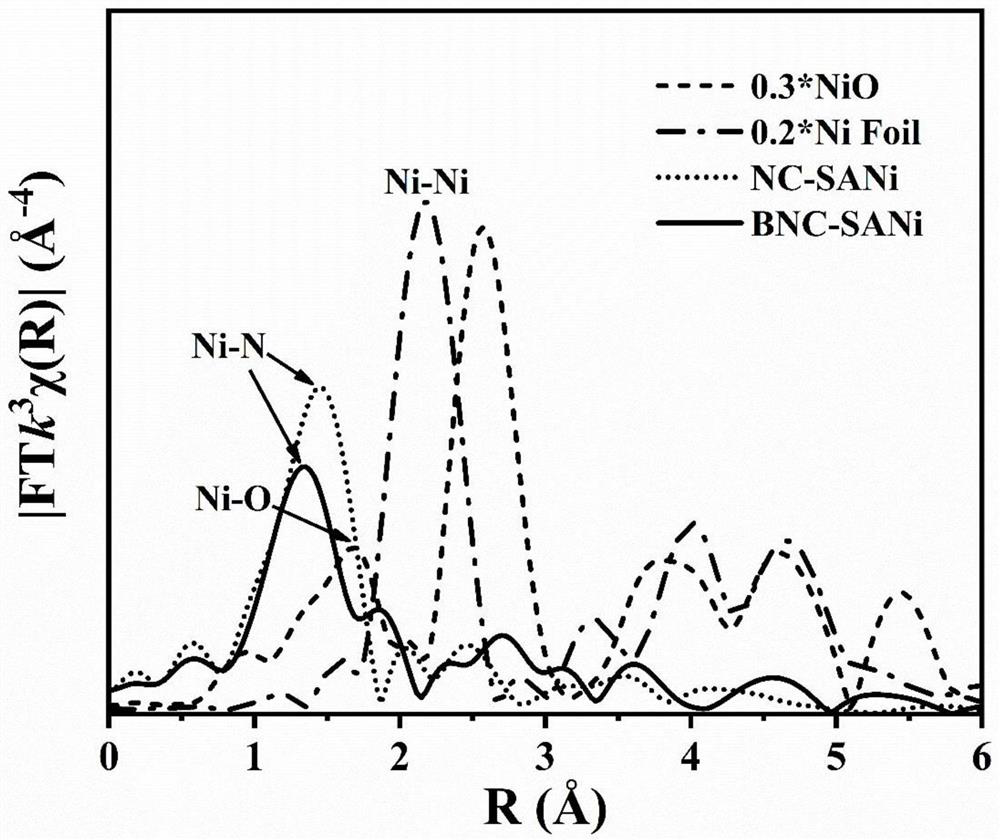

[0059] Dissolve sodium chloride (10 g), glucose (0.75 g), boric acid (30 mg) and nickel acetate tetrahydrate (12 mg) in 80 mL of deionized water, and freeze at -50 °C for 12 h; The material was dried at -50°C and 1Pa for 48 hours to sublimate the ice to obtain the precursor. Afterwards, the above-mentioned precursor was placed in a high-temperature tube furnace, and the temperature was raised to 240 °C at 10 °C / min in an atmosphere of argon, and then continued to be heated at 10 °C in a mixed atmosphere of ammonia and argon at a volume ratio of 1:4. °C / min to 400 °C; then continue to heat up to 700 °C at 10 °C / min under an atmosphere of argon, and then keep warm for 30 min in a mixed atmosphere of ammonia and argon with a volume ratio of 1:4, then in argon The atmosphere was kept for 1.5h; then the temperature was raised to 1000°C at 20°C / min under the atmosphere of argon, and the temperature was kept for 1h to obtain the catalyst, which was named as BNC-SANi.

[0060] As mea...

Embodiment 2

[0088] The difference with Example 1 is: the quality of boric acid is 40mg. As measured by XPS, the mass of nickel single atom in the obtained catalyst is 2.40% of the mass of the carbon skeleton, the mass of the nitrogen atom is 13.49% of the mass of the carbon skeleton; the mass of the boron element is 8.61% of the mass of the carbon skeleton.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com