Multiphase-composition tantalum/niobate composite ceramic and preparation method thereof

A technology of composite ceramics and multi-phase composition, applied in the field of materials science and engineering, can solve the problems of inability to prepare composite ceramics, poor mechanical properties of single-phase tantalum/niobate ceramics, etc., to achieve excessive growth of grains and excellent mechanical properties Performance, effect of preventing crack growth

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

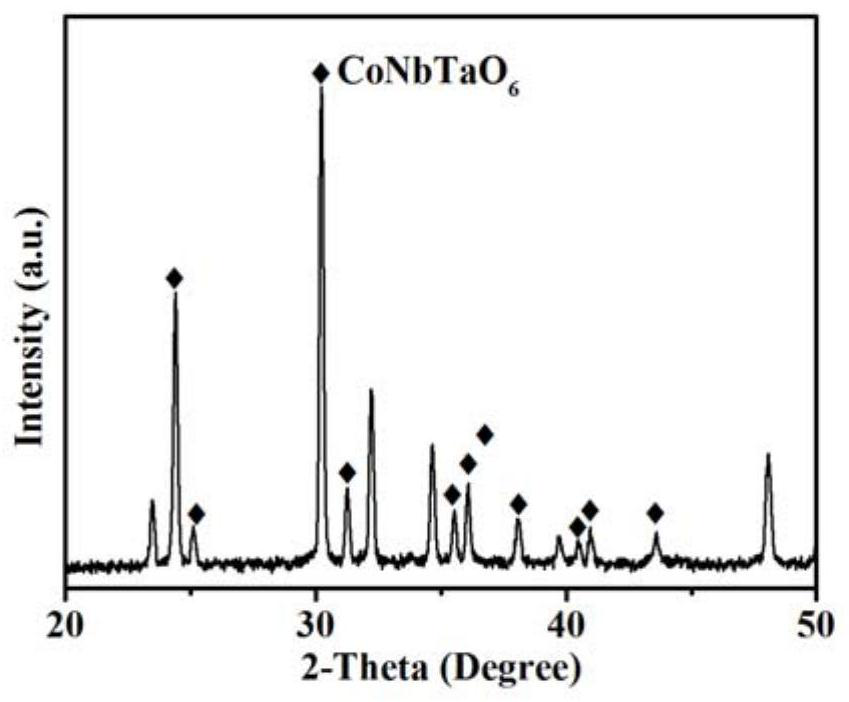

[0030] (1) Co(OH) 2, niobium oxalate and tantalum oxalate are placed in an alumina crucible and then calcined and decomposed in a medium temperature furnace. Co(OH) 2 The calcination temperature is 460°C, and the holding time is 1 hour; the calcination temperature of niobium oxalate and tantalum oxalate is 820°C, and the holding time is 2 hours; corresponding oxide powders are obtained respectively.

[0031] (2) According to (Co 4 NbTaO 9 ) 0.4 (CoNbTaO 6 ) 0.6 Weigh the oxide powder at the molar ratio, add absolute ethanol and place it in a grinder for ball milling and mixing while refining the powder particle size, the speed is 2400 rpm, the grinding and mixing time is 10 hours, and the temperature is kept at 100°C Powder D was obtained after drying for 6 hours.

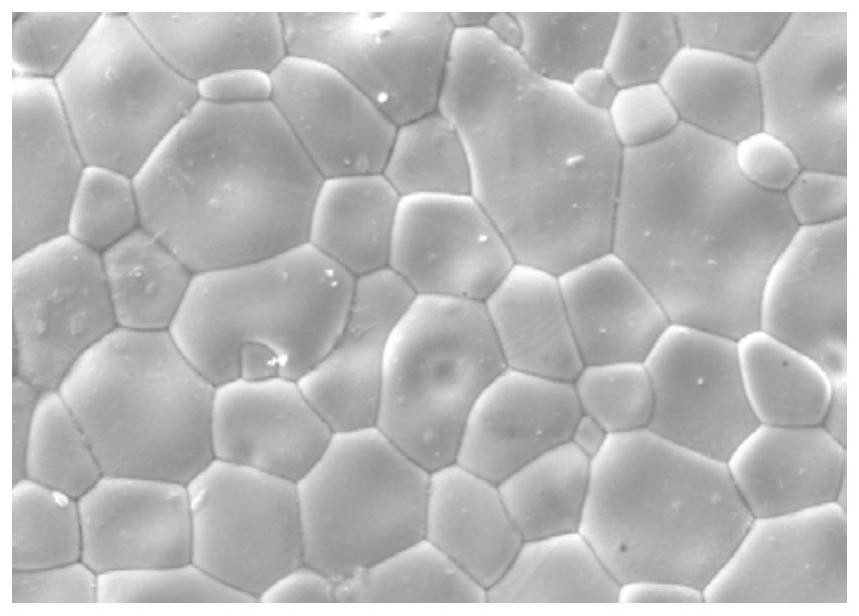

[0032] (3) Weigh 3g of powder D and place it in a cold isostatic press for compression molding, the pressure is 300MPa, the holding time is 2 minutes, and then sintered at 1000°C for 2 hours to finally obtain...

Embodiment 2

[0038] (1) Mg(OH) 2 and niobium oxalate are placed in an alumina crucible and then calcined and decomposed in a medium temperature furnace, Mg(OH) 2 The calcination temperature is 460°C and the holding time is 1 hour; the calcination temperature of niobium oxalate is 820°C and the holding time is 2 hours; corresponding oxide powders are obtained respectively.

[0039] (2) According to (Mg 5 Nb 4 o 15 ) 0.4 (Mg 4 Nb 2 o 9 ) 0.1 (MgNb 2 o 6 ) 0.5 Weigh the oxide powder at the molar ratio, add absolute ethanol and place it in a grinder for ball milling and mixing while refining the powder particle size, the speed is 2000 rpm, the grinding and mixing time is 12 hours, and the temperature is kept at 90°C Powder D was obtained after drying for 6 hours.

[0040] (3) Weigh 2.5g of powder D and place it in a cold isostatic press for compression molding, the pressure is 350MPa, the holding time is 2 minutes, and then sintered at 930°C for 2 hours to obtain a dense (Mg 5 Nb ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com