Rotary furnace carbon-ceramic furnace tube for CVD carbon vapor deposition, rotary furnace and preparation method of carbon-ceramic furnace tube

A technology of chemical vapor deposition and rotary furnace, applied in the direction of gaseous chemical plating, coating, metal material coating process, etc., can solve the problems of easy hydrogen embrittlement, poor oxidation resistance, easy introduction of metal impurities, etc., and achieve the solution of hydrogen Effects of brittle reaction, low cost, and simple preparation method

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

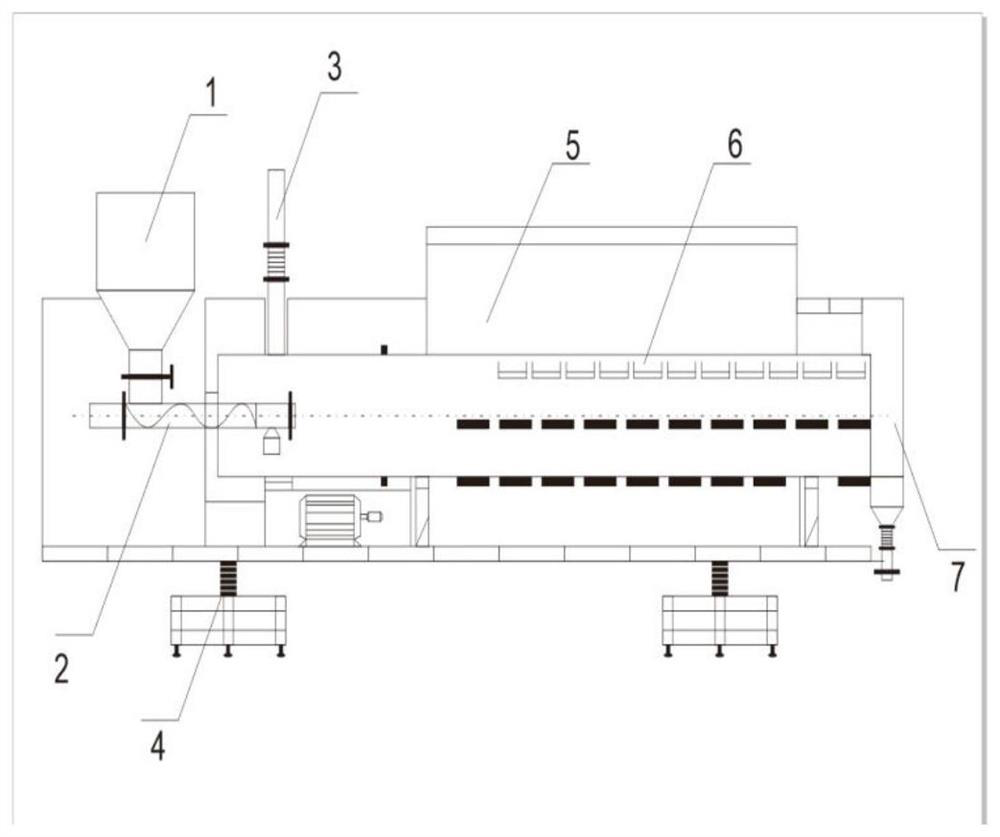

Method used

Image

Examples

Embodiment 1

[0041] 1) multi-layer fabric of carbon fiber fabric (no intersection sheeting) and fetal alternately laminated carbon fiber web, a foam using a cylindrical model, is less than the outer diameter of the cylindrical foam models carbon ceramic tube inner diameter 1cm, and a length greater than the carbon - ceramic tube length 4cm, carbon fiber preform body diameter greater than the tubular rotary kiln furnace carbon finished 1cm ceramic tube, excess length cut in a subsequent machining process. The network no sheeting and tire the model surface of the cylindrical foam are alternately circulated ply, layer 16 superposed layers. Are each needling superposed layers, the needle 30 to / cm 3 Needling density of the composite tubular structure constituted, after 300 ℃, 15h heat curing treatment to give 0.6g / cm 3 Carbon fiber preform.

[0042] 2) The carbon fiber preform by chemical vapor deposition, a chemical vapor deposition process comprises a pretreatment and a isothermal pressure ch...

Embodiment 2

[0047] 1) multi-layer fabric of carbon fiber fabric (no intersection sheeting) and fetal alternately laminated carbon fiber web, a foam using a cylindrical model, is less than the outer diameter of the cylindrical foam models carbon ceramic tube inner diameter 1cm, and a length greater than the carbon - ceramic tube length 4cm, carbon fiber preform body diameter greater than the tubular rotary kiln furnace carbon finished 1cm ceramic tube, excess length cut in a subsequent machining process. The network no sheeting and tire the model surface of the cylindrical foam are alternately circulated ply, layer 16 superposed layers. Are each needling superposed layers, the needle 30 to / cm 3 Needling density of the composite tubular structure constituted, after 300 ℃, 15h heat curing treatment to give 0.6g / cm 3 Carbon fiber preform.

[0048] 2) The carbon fiber preform by chemical vapor deposition, a chemical vapor deposition process comprises a pretreatment and a isothermal pressure ch...

Embodiment 3

[0053] 1) multi-layer fabric of carbon fiber fabric (no intersection sheeting) and fetal alternately laminated carbon fiber web, a foam using a cylindrical model, is less than the outer diameter of the cylindrical foam models carbon ceramic tube inner diameter 1cm, and a length greater than the carbon - ceramic tube length 4cm, carbon fiber preform body diameter greater than the tubular rotary kiln furnace carbon finished 1cm ceramic tube, excess length cut in a subsequent machining process. The network no sheeting and tire the model surface of the cylindrical foam are alternately circulated ply, layer 16 superposed layers. Are each needling superposed layers, the needle 30 to / cm 3 Needling density of the composite tubular structure constituted, after 300 ℃, 15h heat curing treatment to give 0.6g / cm 3 Carbon fiber preform.

[0054] 2) The carbon fiber preform by chemical vapor deposition, a chemical vapor deposition process comprises a pretreatment and a isothermal pressure ch...

PUM

| Property | Measurement | Unit |

|---|---|---|

| density | aaaaa | aaaaa |

| bending strength | aaaaa | aaaaa |

| bending strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com