Anchor rod recycling device

A recovery device and anchor rod technology, which is applied in the installation of anchor rods, mining equipment, earthwork drilling, etc., can solve the problems of tearing the belt conveyor belt, damage to the cutter of the coal cutter, and difficult removal of the anchor rod, so as to achieve convenient drilling Anchor, extended service life, labor-intensive effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0026] like Figure 1-4 As shown, a bolt recovery device includes a bolt recovery device body 1, a coring drill 2 is provided on one end of the anchor recovery device body 1, and a large-diameter thin-walled surface is provided on one side of the coring drill 2. The drill auger 3 is provided with a core claw 4 on one side of the outer surface of the large-diameter thin-walled auger 3 , and a joint 5 is provided on the outer surface of the other end of the bolt recovery device body 1 .

Embodiment 2

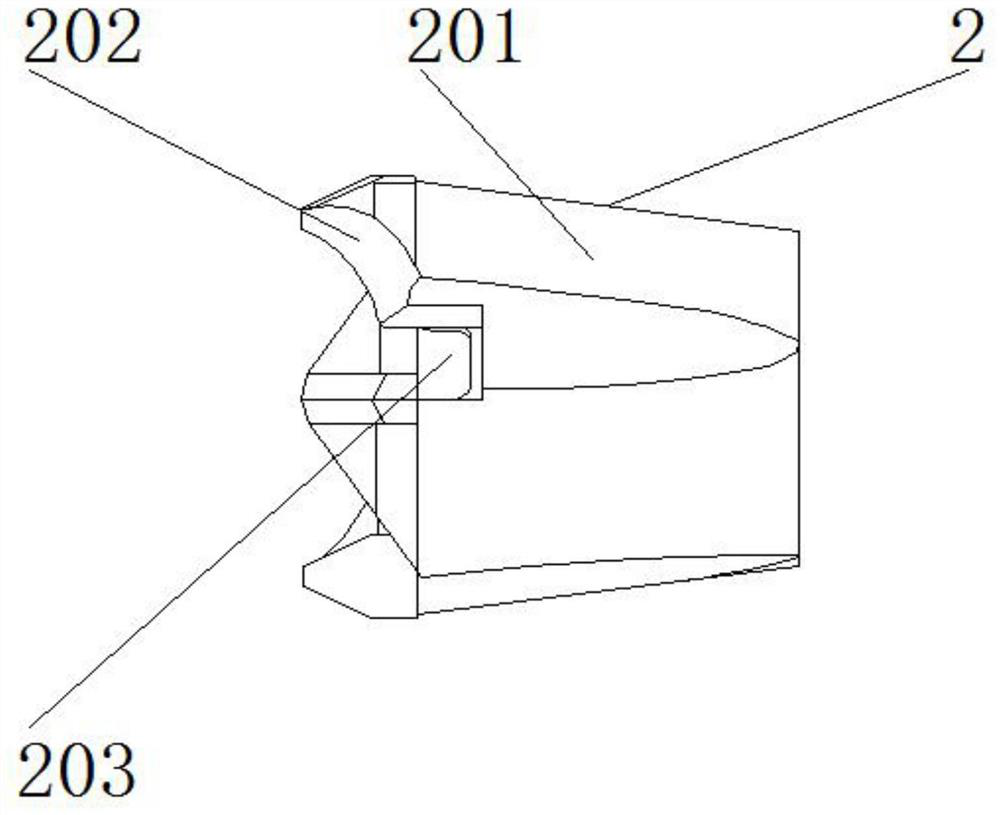

[0028] On the basis of Embodiment 1, such as figure 2 As shown, a fixing assembly is arranged between the drill body 201 and the cemented carbide cutter head 202, and the outer surface of one end of the drill body 201 is fixedly connected with the outer surface of one end of the cemented carbide cutter head 202 through the fixing assembly, and the drill body 201 and the wear-resistant The ring 203 is fixedly connected, and the wear-resistant ring 203 does not damage the original section and strength of the rod body, and the reuse rate is high.

Embodiment 3

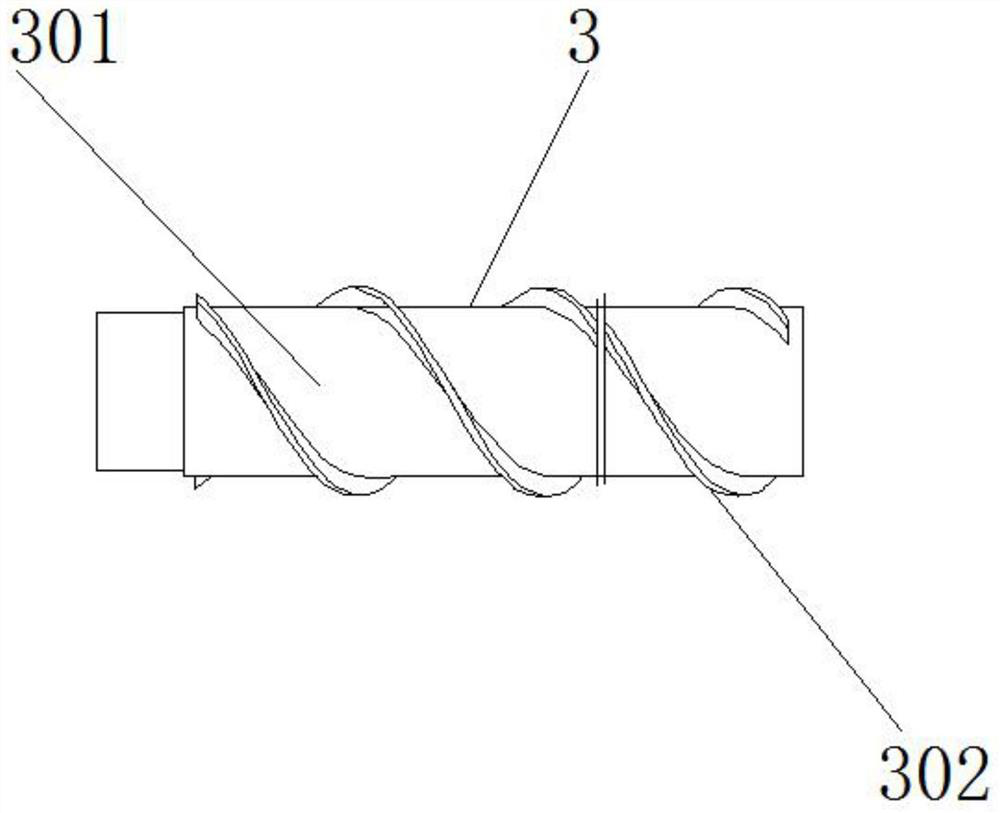

[0030] On the basis of embodiment one and embodiment two, as image 3 As shown, the wear-resistant spiral strip steel 302 is processed on the outer wall of the high-strength geological pipe alloy pipe 301 by mechanical equipment, and the high-strength geological pipe alloy pipe 301 can improve the service life of the overall structure.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com