Method for preparing CO through CO2 catalytic hydrogenation with cobalt-based catalyst

A technology of cobalt-based catalysts and oxidants, which is applied in the direction of catalysts, molecular sieve catalysts, carbon compound catalysts, etc., and can solve problems such as low activity, migration, and loss

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

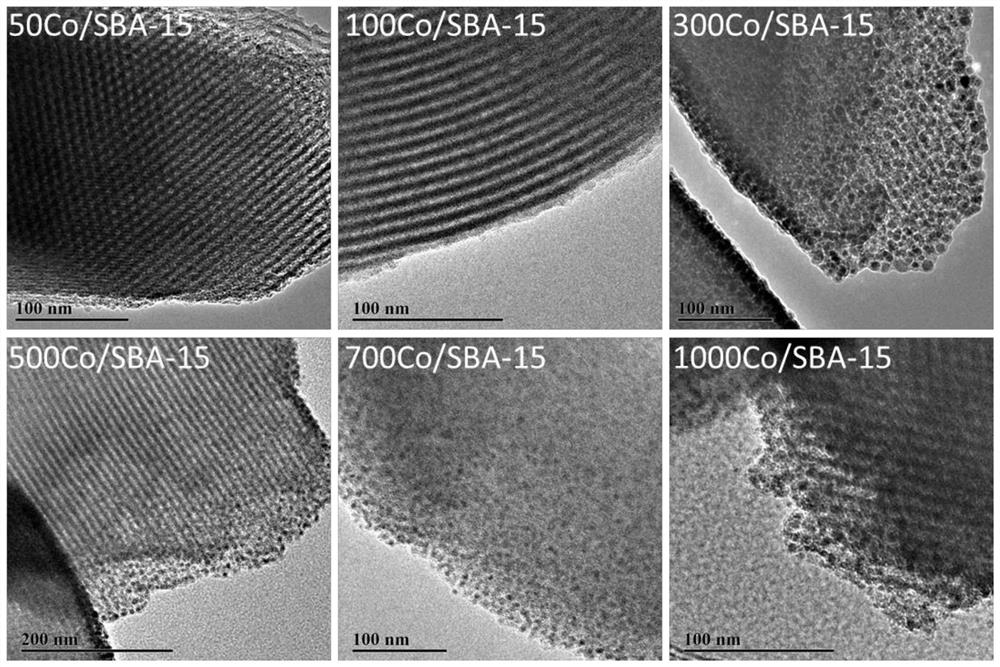

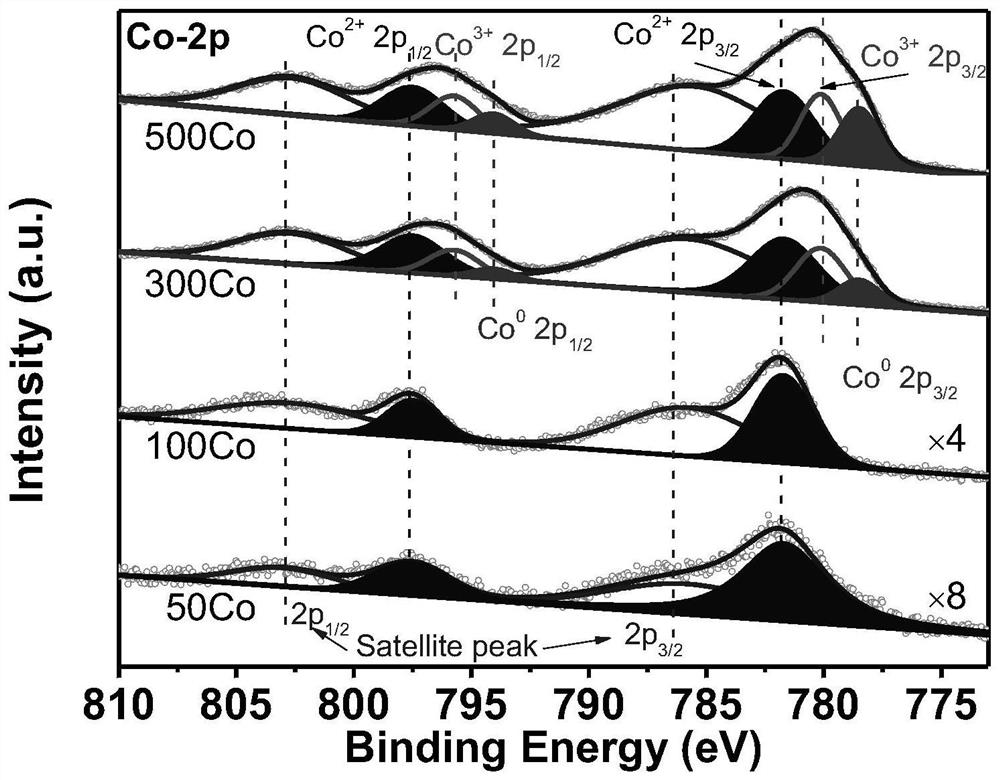

[0033] The mass percentage of Co element in the cobalt-based catalyst of this embodiment is 2.6%, which is composed of SBA-15 substrate and cobalt active center supported on the surface of SBA substrate, wherein the cobalt active center is cobalt in divalent state.

[0034] The preparation method of the cobalt-based catalyst of the present embodiment comprises the following steps:

[0035] (1) Evenly disperse the SBA-15 matrix in the ethanol solution to obtain a suspension with a concentration of 0.01g / mL; evenly coat the suspension on the surface of the glass sheet, and after drying, put the glass sheet into the atomic deposition vacuum reaction In the chamber, the temperature of the reaction chamber is 250°C, the pressure is 90Pa, and the volume ratio of the carrier gas to the vacuum reaction chamber is 1 / 6min -1 Filled with carrier gas, the flow rate of carrier gas is fixed during the deposition process;

[0036] (2) First pulse the Co precursor dicobalt on the surface of th...

Embodiment 2

[0041] The mass percentage of Co element in the cobalt-based catalyst of this embodiment is 5.4%, which is composed of SBA-15 substrate and cobalt active center supported on the surface of SBA substrate, wherein the cobalt active center is cobalt in divalent state. The preparation method of the cobalt-based catalyst of this example is basically the same as that of Example 1, the only difference being that the number of repetitions of step (4) in Example 2 is 100 times.

Embodiment 3

[0043] The mass percentage of Co element in the cobalt-based catalysts in Examples 3-5 is 5.4%, which is composed of SBA-15 substrate and cobalt active center supported on the surface of SBA substrate, wherein the cobalt active center is cobalt in divalent state. The preparation method of the cobalt-based catalyst of Examples 3-5 is basically the same as that of Example 2, the only difference being that the temperature during reduction in step (5) in Example 3 is 150°C; The temperature at the time was 250° C.; the temperature at the time of reduction in step (5) in Example 5 was 350° C.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com