Lithium carbonate-halloysite nanotube as well as preparation method and application thereof

A technology of halloysite nanotubes and lithium carbonate, which is applied in the field of concrete mineral admixtures to achieve the effects of reducing damage, easy handling, and improving strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

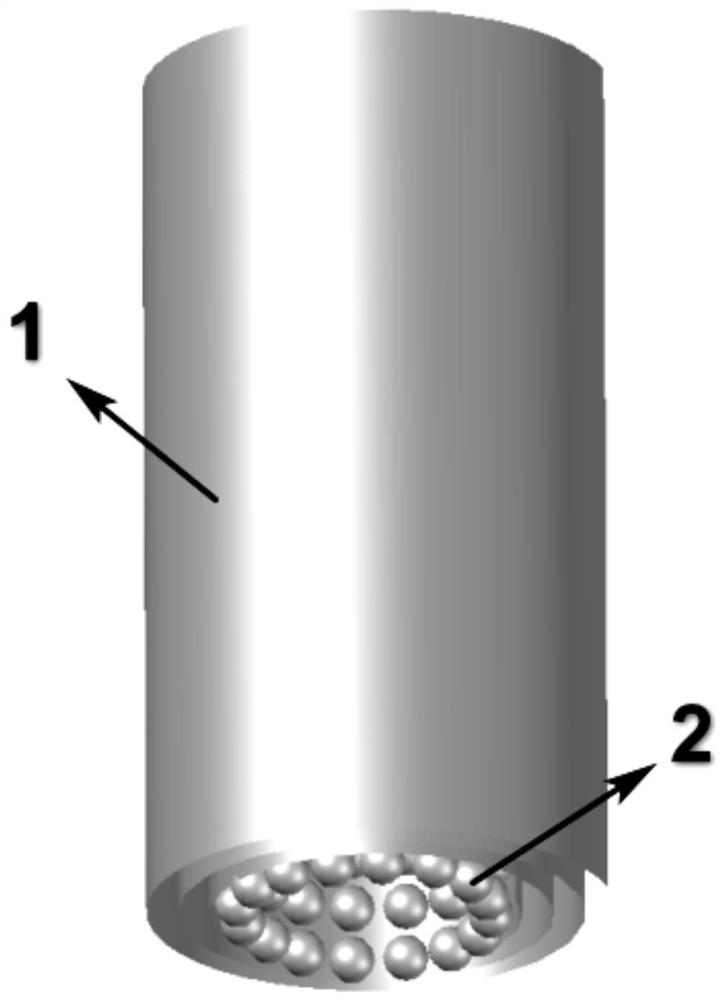

Image

Examples

Embodiment 1

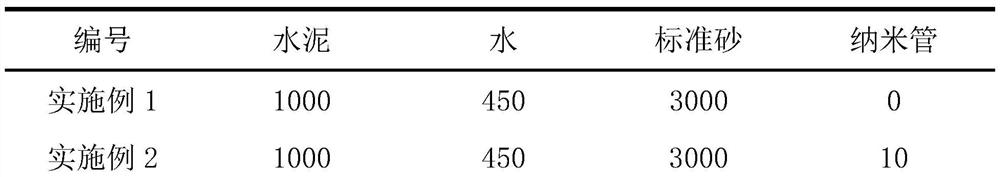

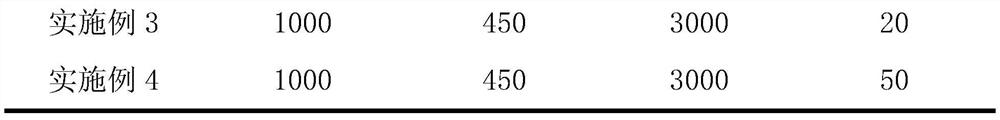

[0053] With a water-cement ratio of 0.45, a mass ratio of cement to standard sand (mortar ratio) of 1:3, and no addition of lithium carbonate-halloysite nanotubes, cement mortar was prepared, and the ingredients were shown in Table 1; this was used as a control group. Refer to the concrete crack resistance test (circle method) to test the crack resistance of the cement mortar specimens. After the mortar is poured, the time is recorded, and the test records the cracking time of the first specimen and the average cracking of the first 5 specimens. The time and test results are shown in Table 2; with this as the control group, the mechanical performance test was carried out on the cement mortar specimen with reference to the standard GB / T50081-2016 for the test method of mechanical properties of ordinary concrete. The test ages were 3d, 7d, and 28d. The test results See Table 3.

Embodiment 2

[0055] With a water-cement ratio of 0.45 and a mass ratio of cement to standard sand (mortar-sand ratio) of 1:3, lithium carbonate-halloysite nanotubes accounting for 1% of the concrete mass percentage were mixed in to prepare cement mortar. The ingredients are listed in Table 1. Show; With reference to the concrete crack resistance test (circle method), the cement mortar specimen is tested for crack resistance, and the time is recorded after the mortar is poured, and the test records the cracking time of the first specimen and the cracking time of the first 5 specimens. The average cracking time, the test results are shown in Table 2; referring to the standard GB / T50081-2016 for the test method of mechanical properties of ordinary concrete, the mechanical properties of the cement mortar specimens were tested, and the test ages were 3d, 7d, and 28d. The test results are shown in Table 3.

Embodiment 3

[0057] With a water-cement ratio of 0.45 and a mass ratio of cement to standard sand (mortar-sand ratio) of 1:3, lithium carbonate-halloysite nanotubes accounting for 2% of the concrete mass percentage were mixed to prepare cement mortar. The ingredients are listed in Table 1. Show; With reference to the concrete crack resistance test (circle method), the cement mortar specimen is tested for crack resistance, and the time is recorded after the mortar is poured, and the test records the cracking time of the first specimen and the cracking time of the first 5 specimens. The average cracking time, the test results are shown in Table 2; referring to the standard GB / T50081-2016 for the test method of mechanical properties of ordinary concrete, the mechanical properties of the cement mortar specimens were tested, and the test ages were 3d, 7d, and 28d. The test results are shown in Table 3.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com