Ethylene low-temperature purification device

An ethylene and low-temperature technology, applied in the field of low-temperature purification devices for ethylene, can solve the problems of aggravating the global warming effect and economic losses, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

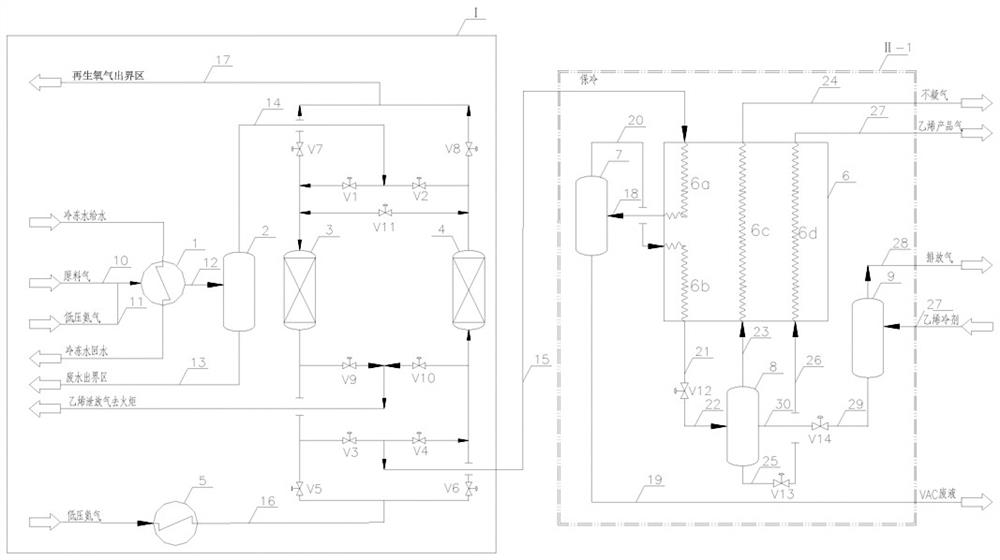

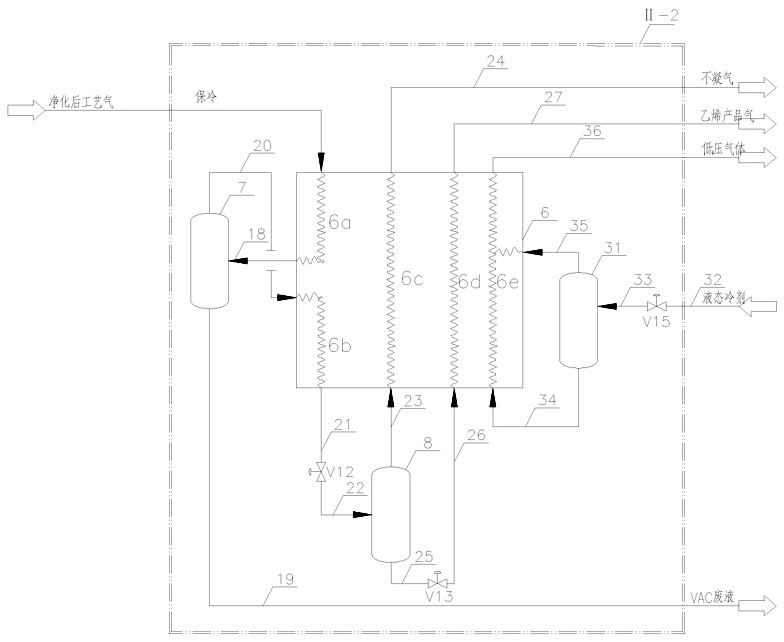

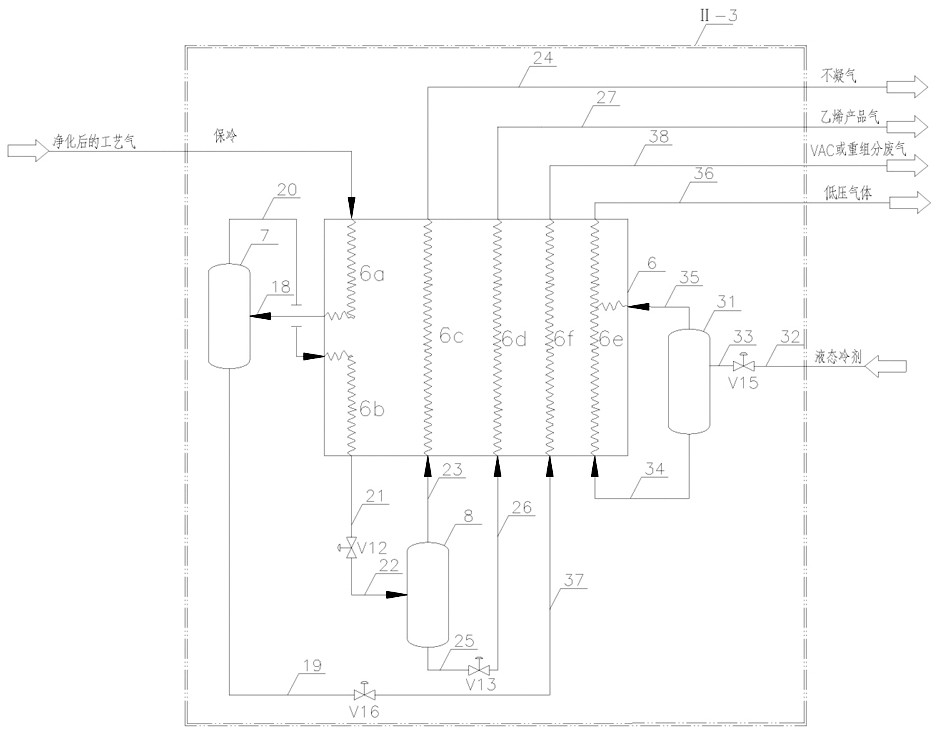

[0016] Below in conjunction with accompanying drawing, the present invention is described in detail: as figure 1 As shown, a low-temperature purification device for ethylene consists of molecular sieve adsorption and purification unit I, low-temperature separation cold box unit II, and refrigerant replenishment system, which are connected by pipelines. There are a raw gas pre-cooling heat exchanger 1, a water separation tank 2, a first molecular sieve adsorber 3, and a second molecular sieve adsorber 4, wherein one end of the raw gas pre-cooling heat exchanger 1 is connected to the external raw material gas through a pipeline, and the other end passes through The pipeline is connected to the water separation tank 2, and the top of the water separation tank 2 is provided with a gas pipeline, which is respectively connected to the first molecular sieve adsorber 3 and the second molecular sieve adsorber 4, and a sewage pipeline 13 is arranged at the bottom thereof, which is connec...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com