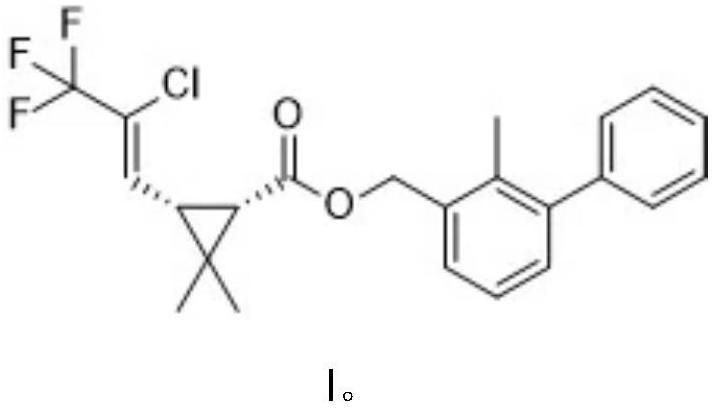

Preparation method of bifenthrin insecticide intermediate

A solvent and catalyst technology, applied in the field of pesticides, can solve problems such as safety risks, low yields, and high costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

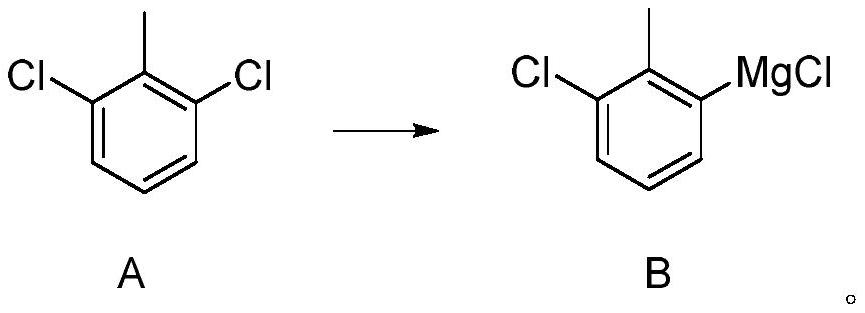

[0048] Example 1 Preparation of Compound B

[0049]

[0050] THF (50 mL), Compound A (20g) and magnesium powder (194 g) were added to a 3L three flask (194 g), and 1.2-dibromoethane (1.5 mL) was added, and the mixture was stirred to 40 ° C to initiate the reaction, slowly dropped the formulated compound. A of the tetrahydrofuran solution (980 g of Compound A is dissolved in 1.2 L tetrahydrofuran), and then stirred at 80 ° C after drying 1 h. Cooling, saving for use.

Embodiment 2

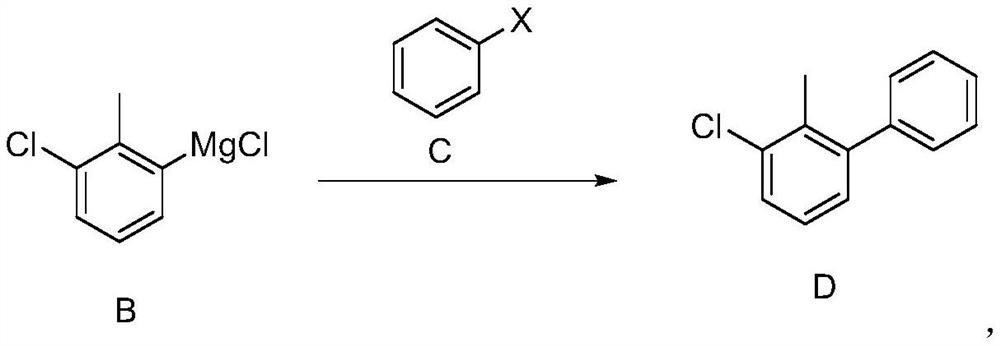

[0051] Example 2 Preparation of Compound D

[0052]

[0053] Add compound C (2 kg) and MnCl to 10L reactor 2 (100 g), nitrogen replacement twice, warmed to 80 ° C to 96 ° C, and slowly added a compound B reaction (3L) obtained according to the preparation method in Example 1. Stirring was continued at 85 ° C after drying. After the reaction was complete, the reaction solution was poured into ice hydrochloric acid (3 mol / L, 2.8L), extracted twice with DCM (0.7 L * 2), combined with organic phases, reverse washing with water (0.7L), anhydrous sulfuric acid Sodium dried over, concentrated under reduced pressure, resulting in compound D, 0.56 kg, two-step income rate: 45%, purity 98.5%.

[0054] HNMR (CD 3 OD) PPM: 7.44-7.40 (m, 2H), 7.37-7.34 (m, 2H), 7.26-7.24 (D, 2H), 7.20-7.16 (T, 1H), 7.12-7.10 (D, 1H), 2.25 (s, 3h).

Embodiment 3

[0055] Example 3 Preparation of Compound D

[0056] Compound C (2 kg) and PD / C (100 g) were added to a 10L reaction kettle, and the nitrogen was replaced twice, and the compound B reaction solution obtained by slowly dropped according to the preparation method in Example 1 was added to 80-96 ° C. . After stirring at 85 ° C, stir it at 85 ° C. After the reaction was complete, the reaction solution was poured into ice hydrochloric acid (3 mol / L, 2.8L), DCM (0.7 L * 2) was extracted twice, combined with organic phases, wash it once with water (0.7L), dry alhydrate sodium sulfate , Concentrated under reduced pressure, resulting in 0.50 kg of compound D, two-step consolidation yield: 33.5%, purity: 98.6%.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com