High-precision wear-resistant special-shaped shear blade and manufacturing method thereof

A manufacturing method and high-precision technology, applied in the direction of manufacturing tools, furnace types, furnaces, etc., can solve problems such as the inability to guarantee the strength of the device, and achieve the effect of ensuring strength, good smoothness, and convenient use

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

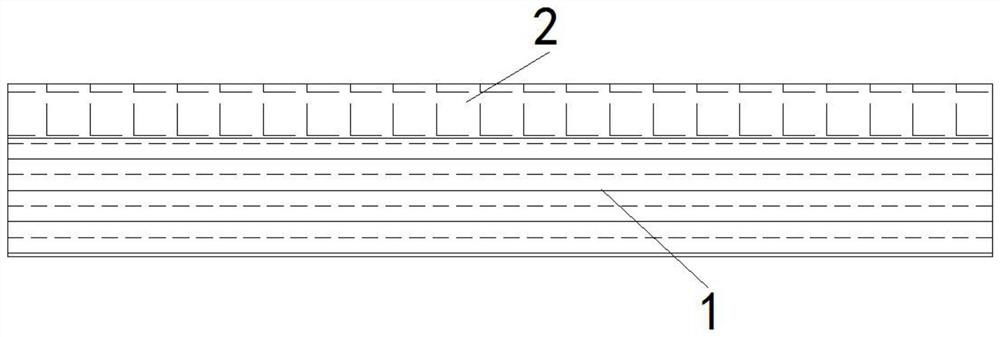

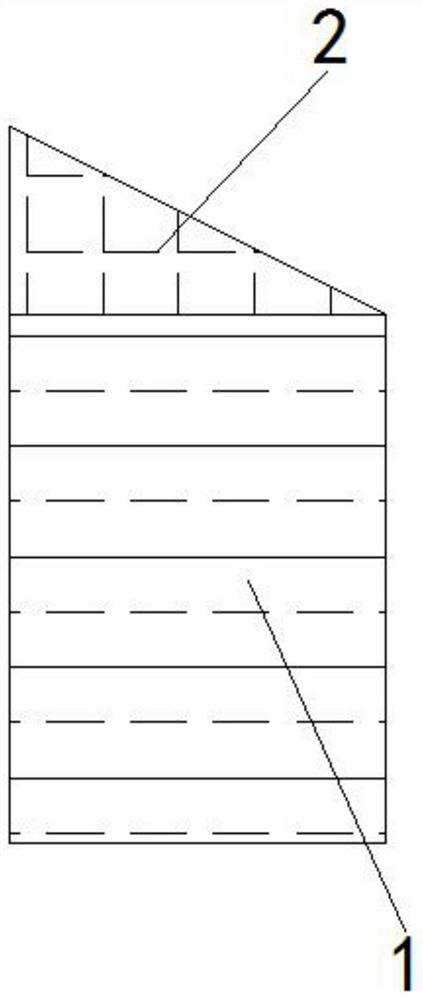

Image

Examples

Embodiment 1

[0036] Embodiment 1: 1 Cut the raw material into a regular shape to make a blank. The ratio of materials used in the blank is: C: 5.55-6.52%; Mn: 0.15-0.40%; Si: 0.50-0.80%; S: 0.020-0.030%; P: 0.02-0.03%; Cr: 6.65-6.95%; Ni: 0.03-0.30%; V: 1.68-2.23%; Mo: 4.53-5.56%; Zr,: 0.01-0.02%; B: 0.027~0.038%, the rest is Fe;

[0037] 2) The molten salt liquid is used as the heating medium, and the industrial furnace is heated by immersing the workpiece in the salt liquid;

[0038] 3) Put the forged blank in step 1 into the annealing furnace and raise the temperature to 300°C at a heating rate of 5°C / min. After holding for 30 minutes, continue to heat up to 500°C at a heating rate of 8°C / min and hold for 18 minutes Then continue to heat up to 700°C with a heating rate of 10°C / min, heat it up to 890°C and keep it warm for 260 minutes, then cool it to 400°C in the annealing furnace;

[0039] 4) Heating the cooling substance again, the heating temperature reaches 540°C for 4 to 8 hours,...

Embodiment 2

[0041]Embodiment 2: 1) Cut the raw materials into regular shapes to manufacture blanks. The ratio of materials used in the blanks is: C: 5.55-6.52%; Mn: 0.15-0.40%; Si: 0.50-0.80%; S: 0.020-0.030% ; P: 0.02~0.03%; Cr: 6.65~6.95%; Ni: 0.03~0.30%; ;B: 0.027~0.038%, the rest is Fe;

[0042] 2) The molten salt liquid is used as the heating medium, and the industrial furnace is heated by immersing the workpiece in the salt liquid;

[0043] 3) Put the forged blank in step 1 into the annealing furnace and raise the temperature to 300°C at a heating rate of 5°C / min. After holding for 31 minutes, continue to heat up to 550°C at a heating rate of 8°C / min and hold for 19 minutes Then continue to heat up to 780°C, the temperature rise rate is 10°C / min, heat up to 890°C and keep it warm for 260 minutes, and cool it to 480°C in the annealing furnace;

[0044] 4) Heating the cooling substance again, the heating temperature reaches 560°C for 4 to 8 hours, and then puts into industrial sodiu...

Embodiment 3

[0046] Embodiment 3: 1) Cut the raw material into a regular shape to make a blank. The material ratio of the blank is: C: 5.55-6.52%; Mn: 0.15-0.40%; Si: 0.50-0.80%; S: 0.020-0.030% ; P: 0.02~0.03%; Cr: 6.65~6.95%; Ni: 0.03~0.30%; ;B: 0.027~0.038%, the rest is Fe;

[0047] 2) The molten salt liquid is used as the heating medium, and the industrial furnace is heated by immersing the workpiece in the salt liquid;

[0048] 3) Put the forged blank in step 1 into the annealing furnace and raise the temperature to 300°C at a heating rate of 5°C / min. After holding for 32 minutes, continue to heat up to 560°C at a heating rate of 8°C / min and hold for 19 minutes Then continue to heat up to 800°C, the heating rate is 10°C / min, heat up to 890°C and keep it warm for 260 minutes, and cool down to 500°C in the annealing furnace;

[0049] 4) Heating the cooling substance again, the heating temperature reaches 560°C for 4 to 8 hours, and then puts into industrial sodium nitrite;

[0050] 5...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com