A kind of multifunctional nano-inorganic composite antibacterial agent for fabric finishing, preparation method and application thereof

A composite antibacterial agent, nano-inorganic technology, applied in fiber treatment, textile and papermaking, biochemical fiber treatment and other directions, can solve the problems of antibacterial agent not resistant to water, easy to fall off, limited in the antibacterial performance of photocatalytic inorganic antibacterial agent, etc. The effect of antibacterial ability, expanding application range, and simple method

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

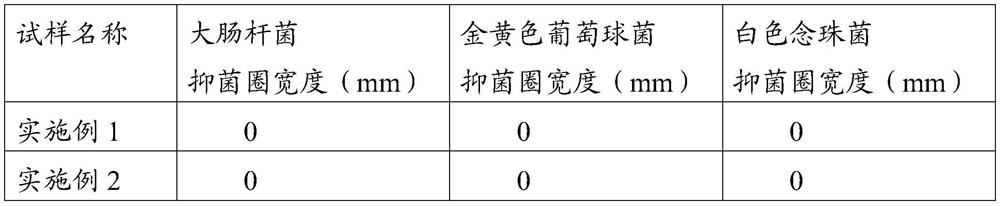

Examples

Embodiment 1

[0041] This embodiment provides a preparation method of a multifunctional nano-inorganic composite antibacterial agent for fabric finishing and a method for antibacterial finishing of cotton fabrics using the multifunctional nano-inorganic composite antibacterial agent for fabric finishing, specifically comprising the following steps:

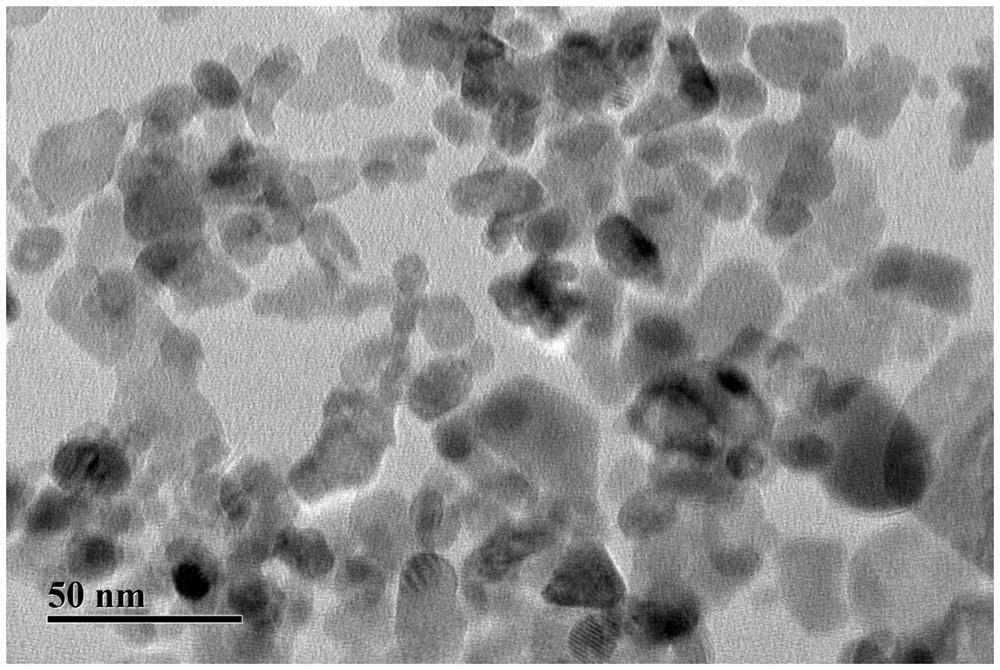

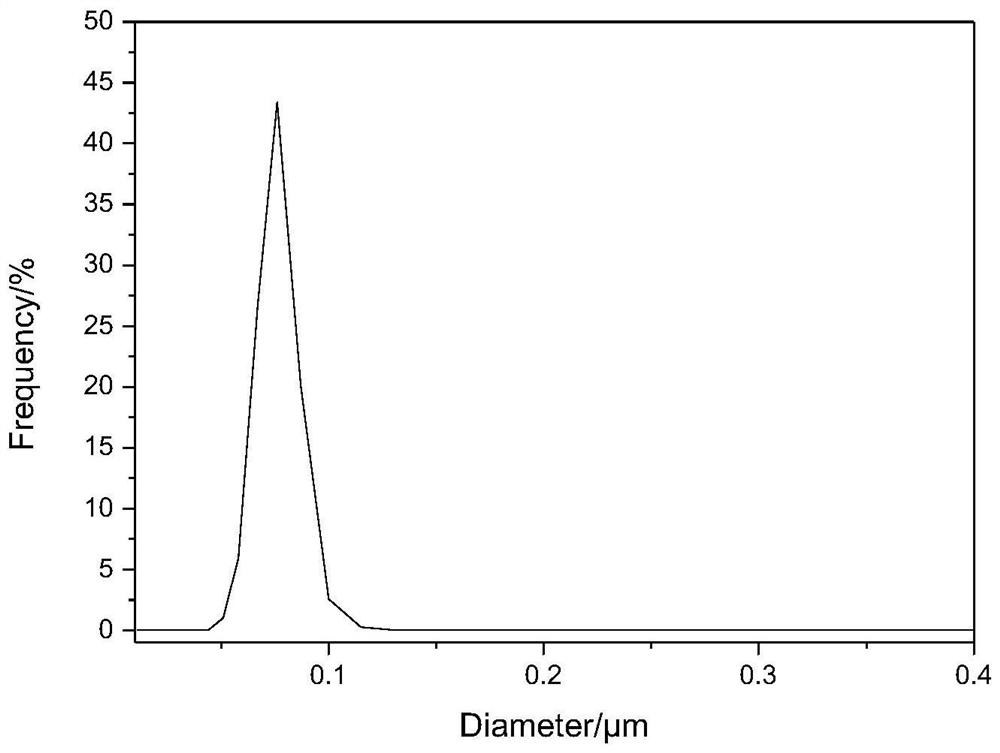

[0042] S1 Preparation of nano-zinc oxide: First, the basic zinc carbonate is pulverized by a jet mill, and then placed in a muffle furnace for sintering treatment at a temperature of 650°C and a heating time of 30 minutes, and then the obtained crude product is jet pulverized again , to obtain the final product rod-shaped nano zinc oxide. The average particle size of the obtained nano-zinc oxide is about 10-20nm, and the specific surface area is 50-70m 2 / g.

[0043] S2g-C 3 N 4 Synthesis of urea: put urea in a corundum crucible and cover it, place it in a muffle furnace, heat it at a rate of 5°C / min to 500°C for 4 hours, then cool it down t...

Embodiment 2

[0051] This embodiment provides a preparation method of a multifunctional nano-inorganic composite antibacterial agent for fabric finishing and a method for antibacterial finishing of cotton fabrics using the nano-zinc oxide composite antibacterial agent, which specifically includes the following steps:

[0052] S1 Preparation of nano-zinc oxide: The basic zinc carbonate is pulverized with a jet mill first, then placed in a muffle furnace for sintering at a temperature of 500°C and a heating time of 50 minutes, and then the obtained crude product is jet pulverized again , to obtain the final product rod-shaped nano zinc oxide.

[0053] S2g-C 3 N 4 Synthesis of melamine: put melamine in a corundum crucible, cover it, place it in a muffle furnace, heat it at a rate of 3°C / min to 550°C for 4 hours, then cool it down to room temperature naturally, then grind and pulverize to obtain a light yellow g-C 3 N 4 powder.

[0054] g-C 3 N 4 Preparation of dispersion: take 0.2g of g-...

Embodiment 3

[0060] This embodiment provides a preparation method of a multifunctional nano-inorganic composite antibacterial agent for fabric finishing and a method for antibacterial finishing of fiber fabrics using the nano-zinc oxide composite antibacterial agent, which specifically includes the following steps:

[0061] S1 Preparation of nano-zinc oxide: The basic zinc carbonate is pulverized with a jet mill first, and then placed in a muffle furnace for sintering treatment at a temperature of 400°C and a heating time of 80 minutes, and then the obtained crude product is jet pulverized again , to obtain the final product rod-shaped nano zinc oxide.

[0062] S2g-C 3 N 4 Synthesis of thiourea: place thiourea in a corundum crucible, cover it, place it in a muffle furnace, heat it at a rate of 4°C / min to 540°C for 4 hours, then cool it down to room temperature naturally, then grind and pulverize to obtain a light yellow g-C 3 N 4 powder.

[0063] g-C 3 N 4 Preparation of dispersion: ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

| concentration | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com