Energy-consumption assembly type flange reinforced concrete support for roadway supporting

A roadway support and assembly technology, applied in tunnels, tunnel linings, shaft equipment, etc., can solve the problems of uncontrollable, prone to brittle failure, not significantly improving the bending stiffness and bending bearing capacity of supports, and reduce energy. The transfer and construction are convenient and fast.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0027] In order to better understand the present invention, the implementation manners of the present invention will be explained in detail below in conjunction with the accompanying drawings.

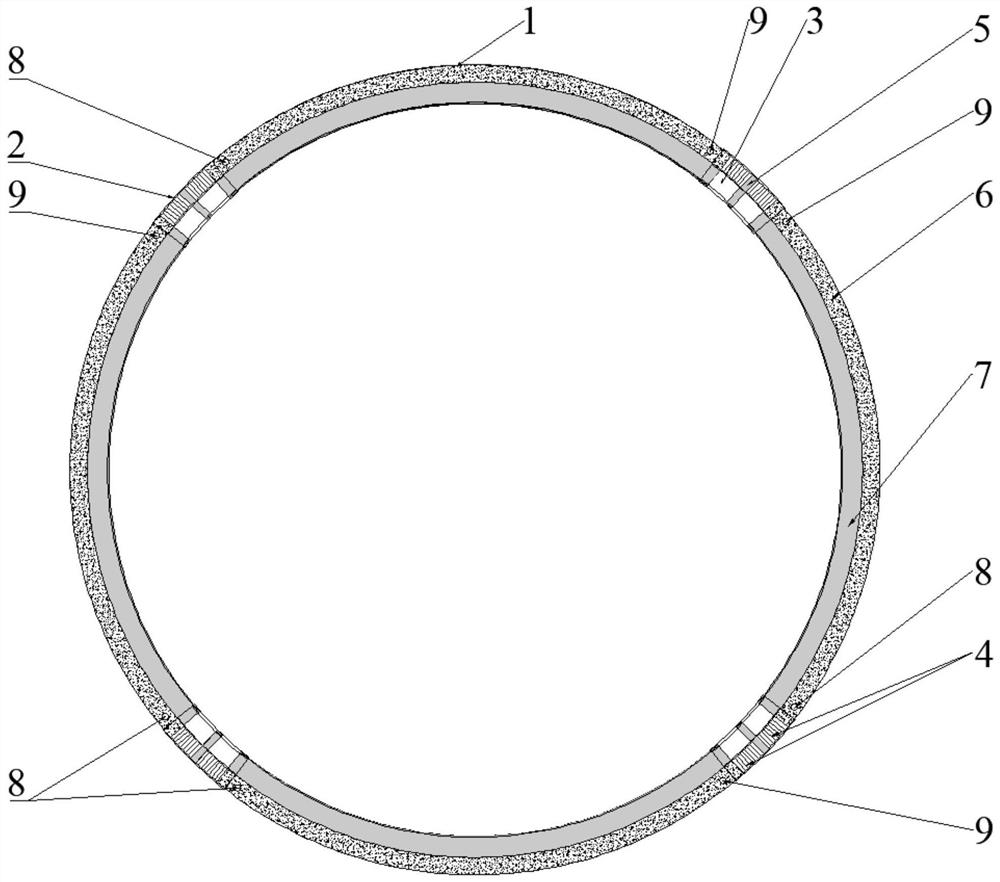

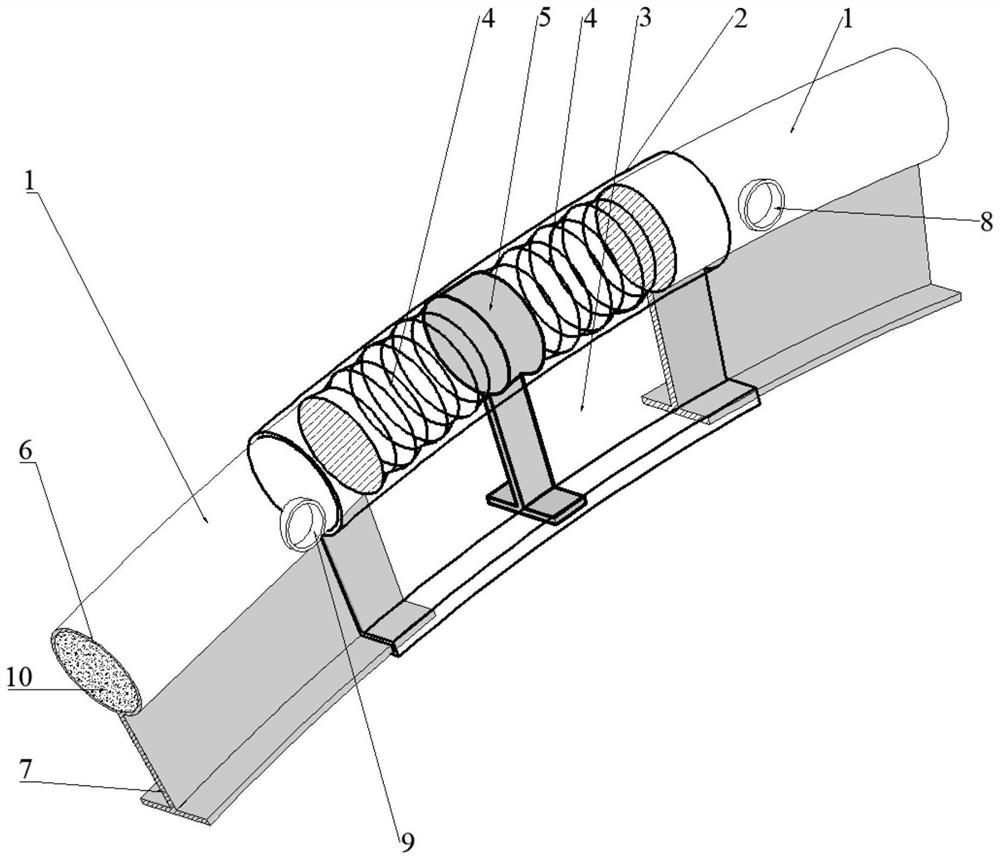

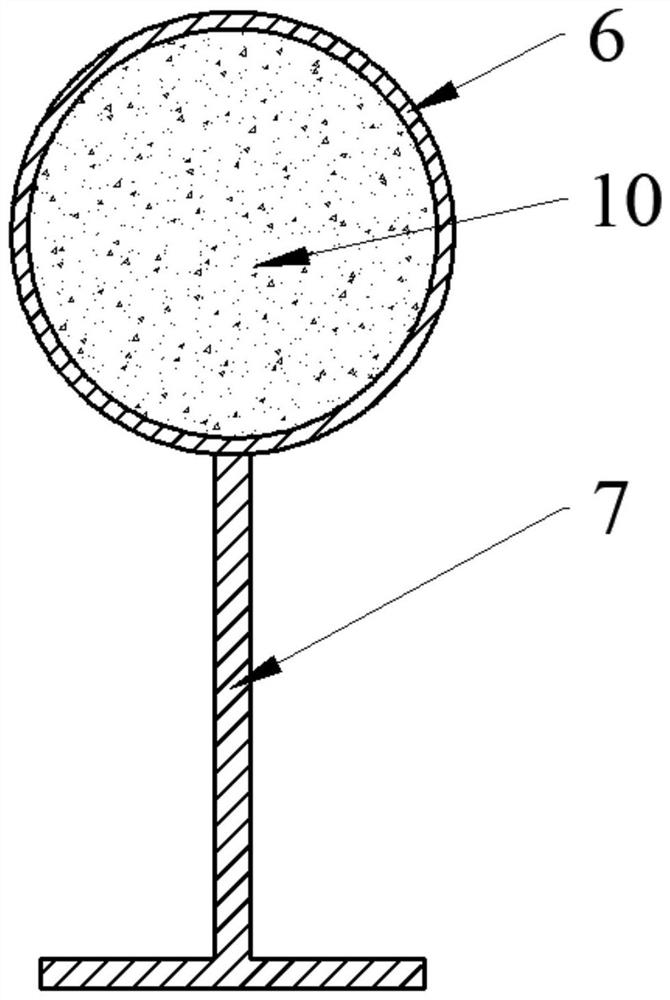

[0028] Such as figure 1 As shown, an energy-dissipating assembled flange-reinforced-concrete support for roadway support includes arc-shaped flange-reinforced-concrete members (1) and energy-dissipating joints (3); figure 1 , 2 As shown, the hard rubber pressure-bearing body (5) is placed in the middle of the steel casing (2) outside the energy dissipation joint (3), and the metal folded tube (4) is placed symmetrically on both sides, and the metal folded tube (4) and the The hard rubber pressure bearing body (5) abuts, and the metal material used for the metal folded tube (4) should meet the compression ratio when the ultimate pressure is applied (compression ratio = the length of the metal folded tube after ultimate pressure / the metal folded edge before deformation pipe length) i...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Wall thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com