Efficient and energy-saving regenerative heating furnace

A high-efficiency energy-saving heating furnace technology, applied in the field of workpiece forging heating, can solve the problems of exhaust gas pollution, high energy consumption, etc., and achieve the effects of low noise, uniform temperature distribution, and huge energy-saving potential

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

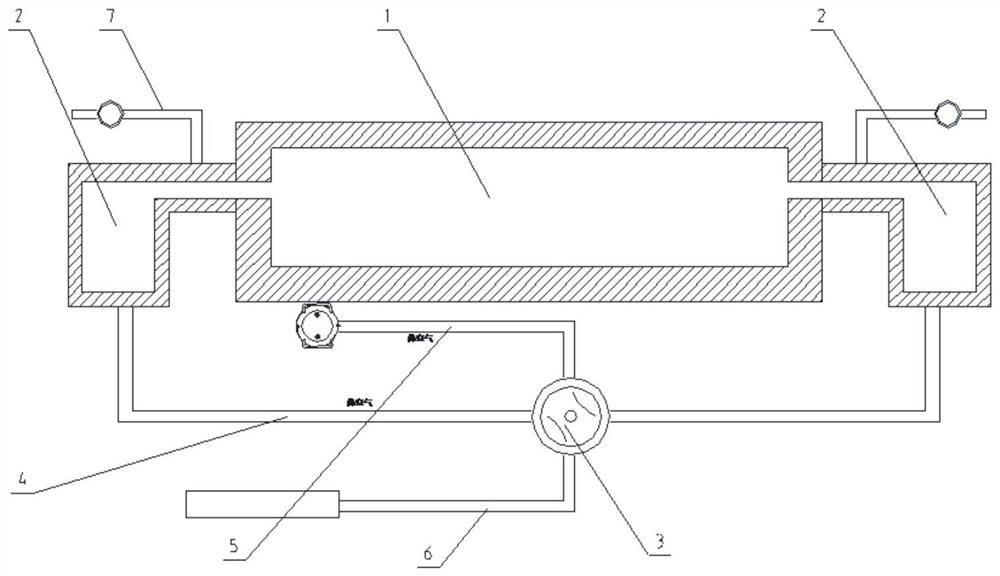

[0032] Embodiment 1: A high-efficiency and energy-saving regenerative heating furnace, including a regenerator 1 and a burner 2 connected to the left and right ends of the regenerator 1 for preheating air and absorbing excess heat; it also includes A reversing valve 3, the reversing valve 3 communicates with the burner 2 with a connecting pipe 4, and the reversing valve 3 is also communicated with an intake pipe and an exhaust pipe; inside the first burner 2 and the second burner 2 All are equipped with heat accumulators.

[0033] The burner 2 is also communicated with a fuel channel for providing fuel oil or gas.

[0034] The regenerator 1 is provided with refractory asbestos mesh, refractory bricks, refractory pick fibers, and refractory steel plates in sequence from the inside to the outside, the air intake pipe is connected to a blower, and the regenerator is a honeycomb ceramic regenerator structure.

[0035] Working principle: After the normal temperature air is switche...

Embodiment example 2

[0036] Implementation Case 2: A heating method for a high-efficiency and energy-saving regenerative heating furnace, comprising the following steps:

[0037] Step 1: Preheat the air to a temperature above 1000°C, mix it with fuel and spray it into the furnace body.

[0038] The second step: form a temperature above 1200 ℃ in the heating furnace body to heat the workpiece;

[0039] Step 3: Use the waste heat generated after heating to absorb the excess heat through the heat storage body, and reciprocate part of the air through the reversing valve 3, and part of it is discharged into the atmosphere;

[0040] Part Four: Repeat the first step to the third step to enter the next cycle.

[0041] After the regenerator is heated, air is introduced, and the air is heated to a high temperature, and then sent into the burner to be mixed with fuel for combustion and heat storage combustion. The regenerators 1 must be in pairs, and one of them is used to heat the air. While the other is ...

Embodiment example 3

[0042]Implementation Case 3: It also includes a pressure channel for upward air supply arranged at the bottom of the regenerator 1, and the pressure channel is connected with a pressure pump for providing intake pressure, so that a downward air flow is formed in the furnace (regenerator 1). The circulation of wind suction from left to right makes the temperature distribution of the regenerator 1 more uniform.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com