Carbamazepine pharmaceutical composition as well as preparation method and application thereof

A technology of carbamazepine and a composition, which is applied in the field of carbamazepine pharmaceutical composition and its preparation, can solve the problems of anemia and malnutrition, electrolyte disturbance, life-threatening and the like, and achieves the advantages of long-term treatment, promotion of digestion and absorption, The effect of promoting gastrointestinal motility

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

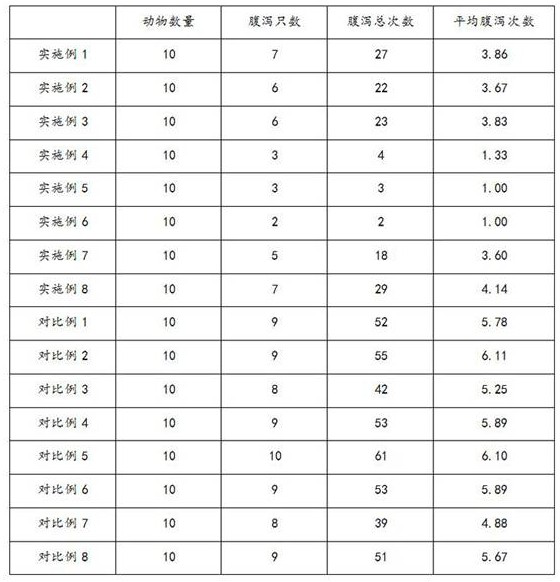

Examples

preparation example Construction

[0029] Second aspect, the embodiment of the present invention also provides a kind of preparation method of carbamazepine pharmaceutical composition, it comprises the following steps:

[0030] 1. Mix carbamazepine, hydroxypropyl cellulose and crospovidone evenly, add water to granulate.

[0031] Specifically, it includes: first crush carbamazepine to 100-120 mesh, put carbamazepine, crospovidone, hydroxypropyl cellulose, starch, cottonseed peptide, and L-arabinose into a wet granulator, mix, add Appropriate amount of purified water, granulated. Wet granulation is carried out with a oscillating granulator, and the mesh size of the screen is 12 to 14 mesh. Wet granules are placed in a high-efficiency boiling dryer, preheated at an inlet temperature of 60-70°C for 10 minutes, and dried at room temperature to control the moisture content of the granules between 2-6%. The dried granules are sized in a swing granulator, and the mesh size of the sieve is 16-18 mesh. Reserve after ...

Embodiment 1

[0038] Present embodiment provides a kind of carbamazepine pharmaceutical composition, and its preparation method is as follows:

[0039] 1. Preparation materials: 120g carbamazepine, 50g hydroxypropyl cellulose, 100g crospovidone, 100g sodium lauryl sulfate, 240g cottonseed peptide.

[0040] 2. Granulation: crush carbamazepine to 120 mesh; put carbamazepine, hydroxypropyl cellulose, starch and crospovidone in a wet granulator, mix for 5 minutes, add an appropriate amount of purified water, and granulate 2 minutes. Wet sizing is carried out with a oscillating granulator, and the mesh number of the sieve is 12 mesh. Wet granules are placed in a high-efficiency boiling dryer, and the dryer is preheated with wind at a temperature of 70°C for 10 minutes, and then dried at room temperature. Control particle moisture at around 2%. The dried granules are sized in a swing granulator, and the mesh number of the sieve is 16 mesh. Reserve after whole grain. Then add sodium lauryl su...

Embodiment 2

[0042] Present embodiment provides a kind of carbamazepine pharmaceutical composition, and its preparation method is as follows:

[0043] 1. Raw materials: 80g carbamazepine, 100g hydroxypropyl cellulose, 50g crospovidone, 50 parts sodium lauryl sulfate, 360g cottonseed peptide and 20g gastric soluble film coating premix.

[0044] 2. Granulation: crush carbamazepine to 100 mesh; put carbamazepine, hydroxypropyl cellulose, starch and crospovidone in a wet granulator, mix for 6 minutes, add an appropriate amount of purified water, and granulate 1 minute. Wet sizing is carried out with a oscillating granulator, and the mesh number of the sieve is 14 mesh. Wet granules are placed in a high-efficiency boiling dryer, and the dryer is preheated with wind at a temperature of 60°C for 15 minutes, and then dried at room temperature. Control particle moisture at about 6%. The dried granules are sized in a swing granulator, and the mesh size of the sieve is 18 mesh. Reserve after whol...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com