Capacitance distribution type carbon fiber composite board and preparation method and application thereof

A carbon fiber and composite board technology, applied in the direction of layered products, instruments, and force measurement, can solve the problems of mechanical properties, difficult high-strength service process, and lack of carbon fiber composite materials, etc., to achieve tight interface, simple steps, and reduce combined area effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

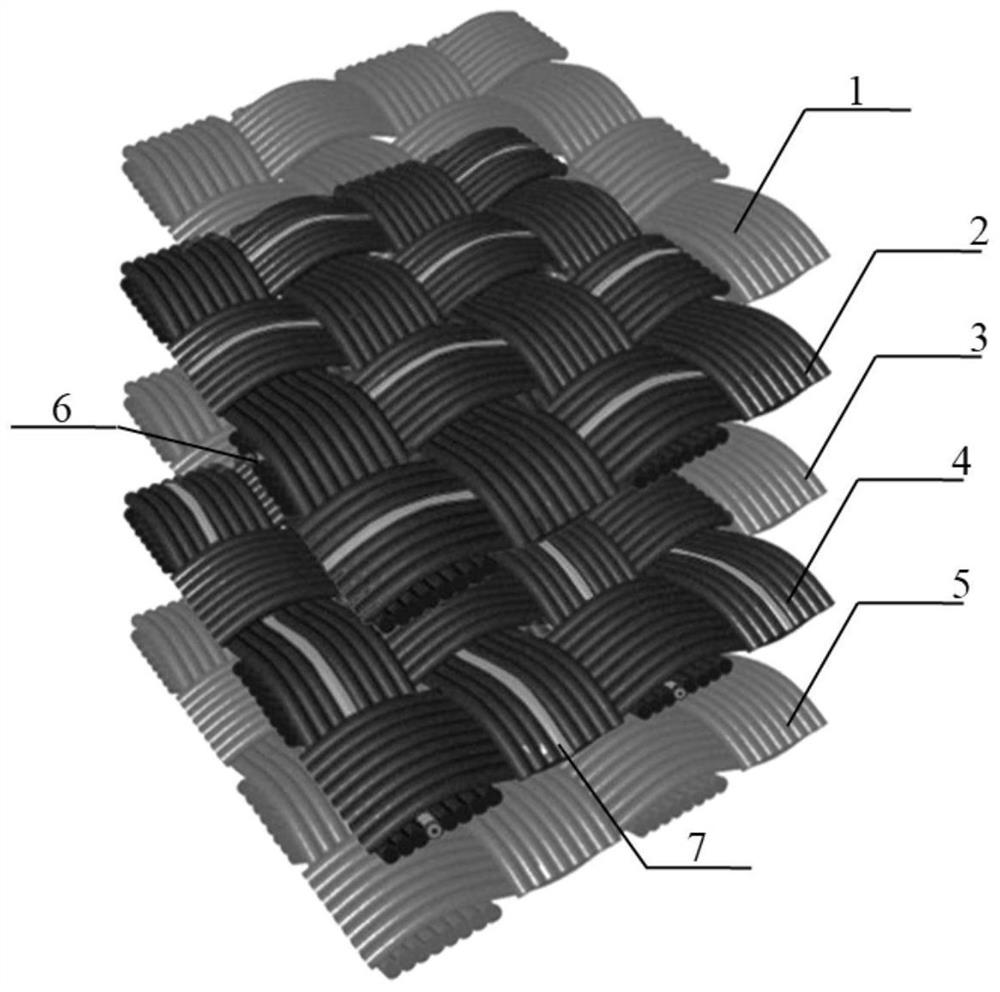

[0061] In this example, if image 3 The capacitance-distributed carbon fiber composite board shown has a five-layer structure, specifically including: the first carbon fiber layer 1, the first sensing fiber layer 2, the second carbon fiber layer 3, the second sensing fiber layer 4, and the third carbon fiber layer 5 , the first carbon fiber layer 1 includes at least one or two layers of carbon fiber cloth, the first sensing fiber layer 2 is formed by interspersing enamelled wire in the carbon fiber cloth at intervals, and the second carbon fiber layer 3 includes one or two layers of carbon fiber cloth, The second sensing fiber layer 4 is formed by interleaving enamelled silk in the carbon fiber cloth at intervals in the weft direction, and the third carbon fiber layer 5 includes one or two layers of carbon fiber cloth. In this embodiment, taking the extreme case of the warp and weft directions, the enameled wires of the first sensing fiber layer 2 and the enameled wires of the...

Embodiment 2

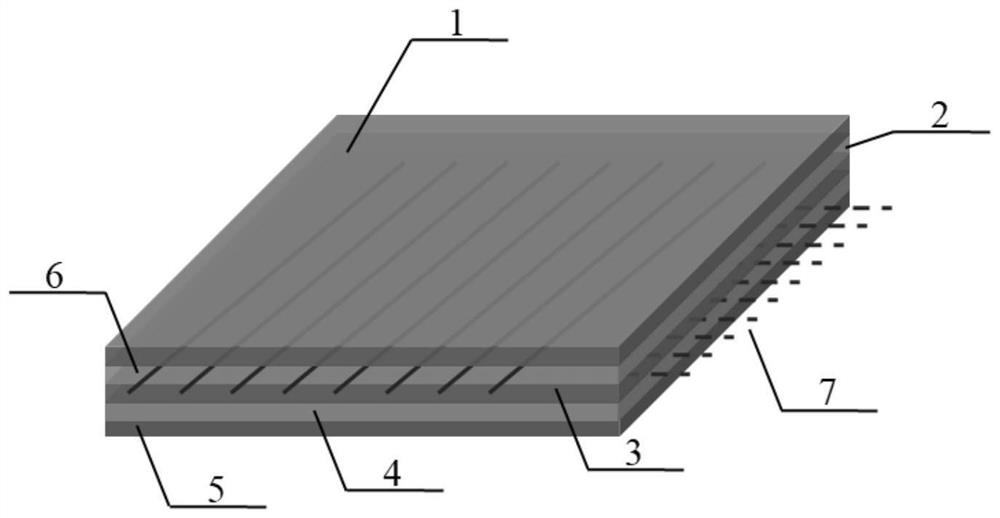

[0067] In this example, if figure 2 The capacitance distributed carbon fiber composite board has a five-layer structure, specifically including: the first carbon fiber layer 1, the first sensing fiber layer 2, the second carbon fiber layer 3, the second sensing fiber layer 4, the third carbon fiber layer 5, the first The carbon fiber layer 1 includes at least one or two layers of carbon fiber cloth. The first sensing fiber layer 2 is formed by interspersing the enamelled wire in the carbon fiber cloth at intervals. The second carbon fiber layer 3 includes one or two layers of carbon fiber cloth. The sensory fiber layer 4 is formed by interleaving enamelled silk in the carbon fiber cloth at intervals in the weft direction, and the third carbon fiber layer 5 includes one or two layers of carbon fiber cloth. In this embodiment, the included angle between the warp sensing fiber 6 and the weft sensing fiber 7 is 90°. When the impact force acts on the composite board, the distance...

Embodiment 3

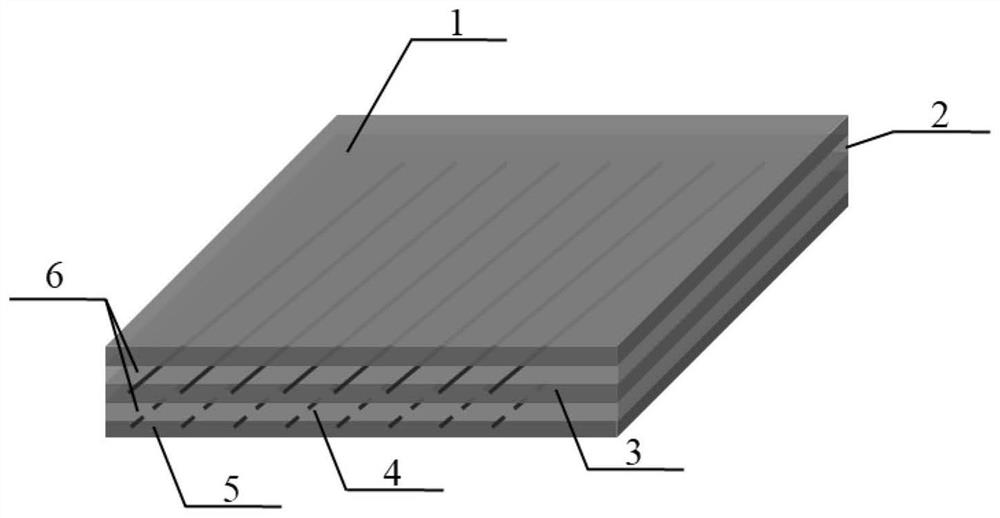

[0069] In this example, if Figure 4The capacitance distributed carbon fiber composite board has a five-layer structure, specifically including: the first carbon fiber layer 1, the first sensing fiber layer 2, the second carbon fiber layer 3, the second sensing fiber layer 4, the third carbon fiber layer 5, the A carbon fiber layer 1 includes at least one or two layers of carbon fiber cloth, the first sensing fiber layer 2 is formed by enamelled wire interspersed in the carbon fiber cloth at intervals, the second carbon fiber layer 3 includes one or two layers of carbon fiber cloth, the second The sensing fiber layer 4 is formed by interleaving enamelled silk in the carbon fiber cloth at intervals in the weft direction, and the third carbon fiber layer 5 includes one or two layers of carbon fiber cloth. In this embodiment, the angle between the first sensing fiber layer 2 and the second sensing fiber layer 4 is 45°, and the enamelled wire of the second sensing fiber layer 4 is...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com