Preparation method of betahistine

A betahistine and solvent technology, which is applied in the field of preparation of betahistine, can solve the problems of low conversion rate, large amount of methylamine salt, and long reaction time, and achieve the effect of short time and reducing the risk of solvent residue

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0047]

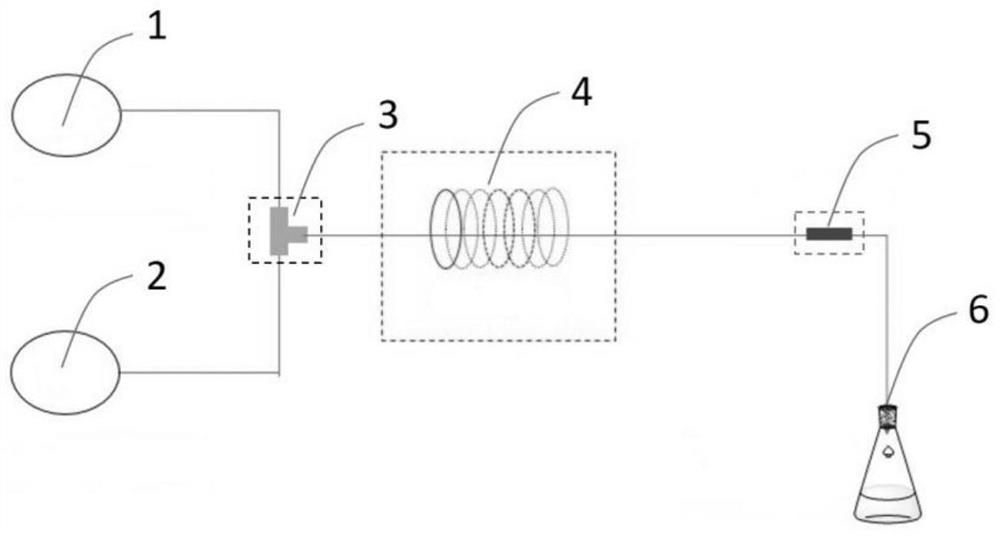

[0048] In the microchannel reaction device, the diameter of the connecting pipe is 1.0mm, and the volume of the microchannel reactor is 2.5mL.

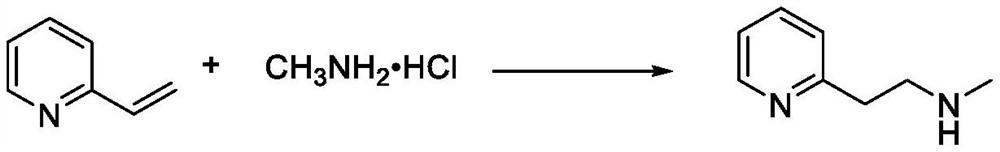

[0049] 1. Take 2-vinylpyridine (3.15g, 30mmol), add ethanol to dilute to 15mL; 2. Take methylamine hydrochloride (4.05g, 60mmol), add water to dilute to 15mL, and use this as reaction solution 1 and Reaction solution 2 is waiting to be fed. Adjust the back pressure valve to control the pressure of the reaction system to 1.0MPa, and connect a section of 2m long pre-cooling pipeline to the front end of the back pressure valve. The temperature heater is controlled to reach 170°C, and the two materials are pumped into the microchannel reactor through the mixer. The fluid of reaction solution 1 flows through the microreactor at 0.5 mL / min, and the fluid of reaction solution 2 flows through the microreactor at 0.5 mL / min. The molar ratio of 2-vinylpyridine to methylamine hydrochloride is 1:2, and the reaction residence time is...

Embodiment 2

[0051] In the microchannel reaction device, the diameter of the connecting pipe is 1.0mm, and the volume of the microchannel reactor is 2.5mL.

[0052] 1. Take 2-vinylpyridine (3.15g, 30mmol), add toluene to dilute to 15mL; 2. Take methylamine hydrochloride (4.05g, 60mmol), add water to dilute to 15mL, and use this as reaction solution 1 and Reaction solution 2 is waiting to be fed. Adjust the back pressure valve to control the pressure of the reaction system to 1.0MPa, and connect a section of 2m long pre-cooling pipeline to the front end of the back pressure valve. The temperature heater is controlled to reach 170°C, and the two materials are pumped into the microchannel reactor through the mixer. The fluid of reaction solution 1 flows through the microreactor at 0.5 mL / min, and the fluid of reaction solution 2 flows through the microreactor at 0.5 mL / min. The molar ratio of 2-vinylpyridine to methylamine hydrochloride is 1:2, and the reaction residence time is 2.5min. The...

Embodiment 3

[0054]

[0055] In the microchannel reaction device, the diameter of the connecting pipe is 1.0mm, and the volume of the microchannel reactor is 2.5mL.

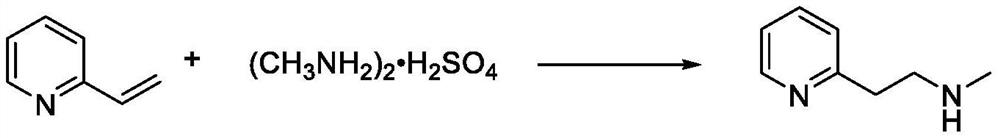

[0056] 1. Take 2-vinylpyridine (3.15g, 30mmol), add toluene and dilute to 15mL; 2. Take methylamine sulfate (4.81g, 30mmol), add water and dilute to 15mL, and use them as reaction solution 1 and reaction Liquid 2 awaits feed. Adjust the back pressure valve to control the pressure of the reaction system to 1.0MPa, and connect a section of 2m long pre-cooling pipeline to the front end of the back pressure valve. The temperature heater is controlled to reach 170°C, and the two materials are pumped into the microchannel reactor through the mixer. The fluid of reaction solution 1 flows through the microreactor at 0.5 mL / min, and the fluid of reaction solution 2 flows through the microreactor at 0.5 mL / min. The molar ratio of 2-vinylpyridine to methylamine hydrochloride is 1:1, and the reaction residence time is 2.5min. The co...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com