Red fluorescent powder and luminescent device with red fluorescent powder

A technology of red phosphor and light-emitting device, which is applied in the field of fluorescent materials, and can solve the problems of low luminous efficiency of red phosphor and low color gamut of light-emitting devices

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

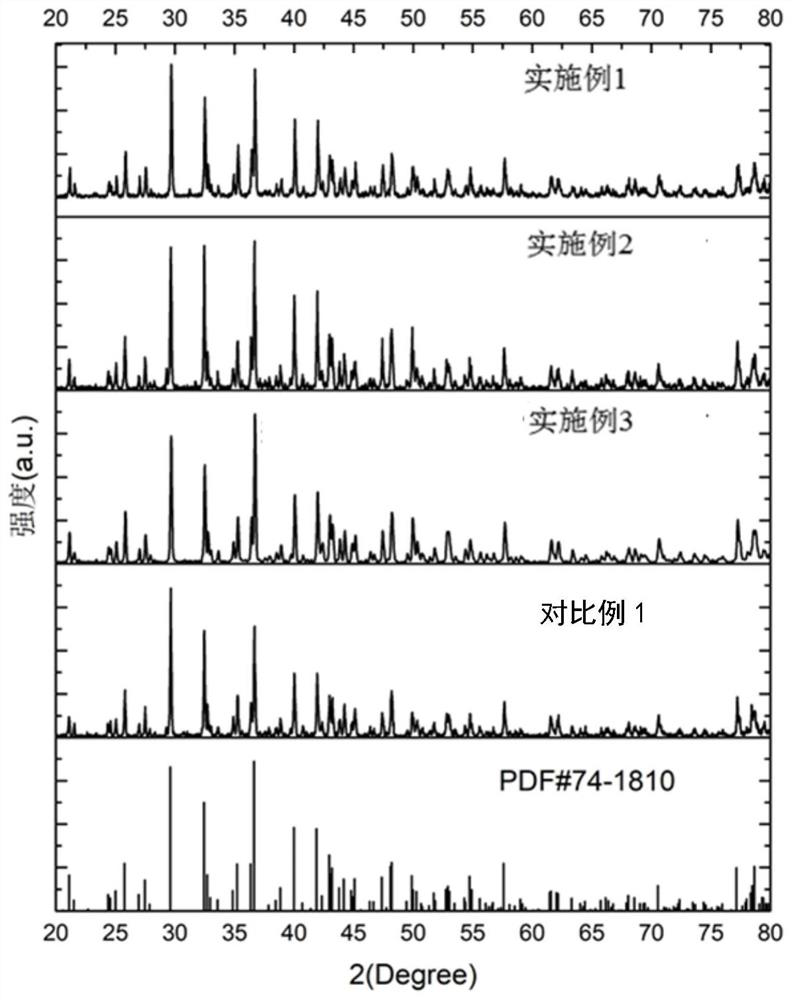

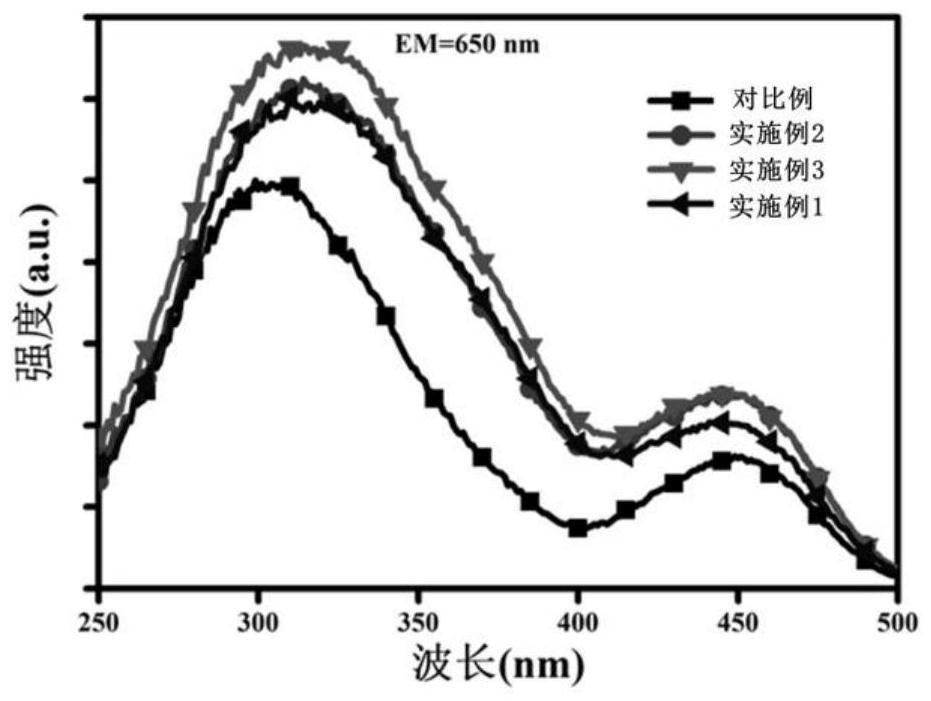

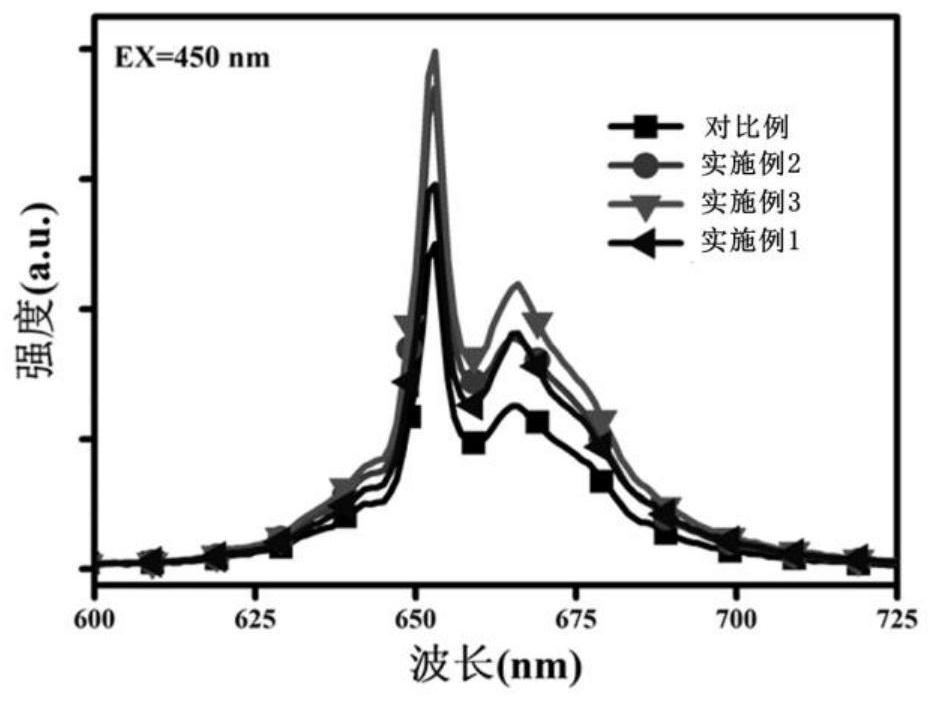

[0029] Press (Sr 3.9 Na 0.1 )(Al 13.93 sc 0.06 )O 25 : 0.01Mn stoichiometric ratio, accurate weighing of SrCO 3 (99.9%),Al 2 o 3 (99.9%), Sc 2 o 3 (99.9%),MnCO 3 (99.9%), Na 2 CO 3 (99.9%) raw materials, and placed in a mortar, fully mixed and ground for 30 minutes to obtain a mixture. Under an air atmosphere, the mixture was raised to 900°C at a rate of 10°C / min and kept for 1 hour, and then heated to 1250°C for 5 hours. The sintered product was obtained after the furnace temperature was naturally lowered to room temperature. After the sintered product was taken out, it was crushed, washed, sieved and then dried to obtain the phosphor powder of Example 1 with a relative emission intensity of 197. Carry out X-ray ray scanning to this fluorescent powder, obtain figure 1 , wherein, the target used is a Co target, the scanning Bragg angle is 20-80°, and the scanning speed is 5° / min; the fluorescence spectrum test of the phosphor is carried out, and the excitation mon...

Embodiment 2

[0031] Press (Sr 3.9 Na 0.4 )(Al 13.93 sc 0.06 )O 25 : 0.01Mn stoichiometric ratio, accurate weighing of SrCO 3 (99.9%),Al 2 o 3 (99.9%), Sc 2 o 3 (99.9%),MnCO 3 (99.9%), Na 2 CO 3 (99.9%) raw materials, and placed in a mortar, fully mixed and ground for 30 minutes to obtain a mixture. In an air atmosphere, the mixture was raised to 900°C at a rate of 10°C / min and kept for 1 hour, and then heated to 1200°C for 4 hours. The sintered product was obtained after the furnace temperature was naturally lowered to room temperature. After the sintered product was taken out, it was crushed, washed, sieved and then dried to obtain the phosphor powder of Example 2 with a relative emission intensity of 200. Carry out X-ray ray scanning to this fluorescent powder, obtain figure 1 , wherein, the target used is a Co target, the scanning Bragg angle is 20-80°, and the scanning speed is 5° / min; the fluorescence spectrum test of the phosphor is carried out, and the excitation spectr...

Embodiment 3

[0033] Press (Sr 3.4 Na 0.6 )(Al 13.93 sc 0.06 )O 25 : 0.01Mn stoichiometric ratio, accurate weighing of SrCO 3 (99.9%),Al 2 o 3 (99.9%), Sc 2 o 3 (99.9%),MnCO 3 (99.9%), Na 2 CO 3 (99.9%) raw materials, and placed in a mortar, fully mixed and ground for 30 minutes to obtain a mixture. Under an air atmosphere, the mixture was raised to 900°C at a heating rate of 10°C / min and kept for 1 hour, then raised to 1350°C and held for 5 hours. After the furnace temperature naturally dropped to room temperature, the sintered product was obtained. After the sintered product was taken out, it was crushed, washed, sieved and then dried to obtain the phosphor powder of Example 3 with a relative emission intensity of 244. Carry out X-ray ray scanning to this fluorescent powder, obtain figure 1 , wherein, the target used is a Co target, the scanning Bragg angle is 20-80°, and the scanning speed is 5° / min; the fluorescence spectrum test of the phosphor is carried out, and the exci...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com