Electrolyte for lithium battery and lithium ion battery

An electrolyte and lithium battery technology, applied in the field of lithium-ion batteries, can solve problems such as low-temperature power performance deterioration, achieve high-temperature storage capacity recovery rate and performance improvement of suppression of gas production, high-temperature storage capacity recovery rate and suppression of gas production improvement, Effect of improving low-temperature DCR performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

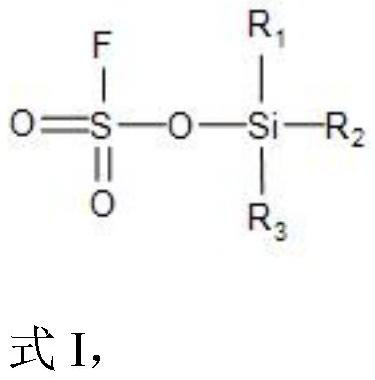

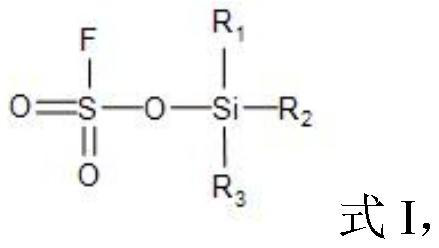

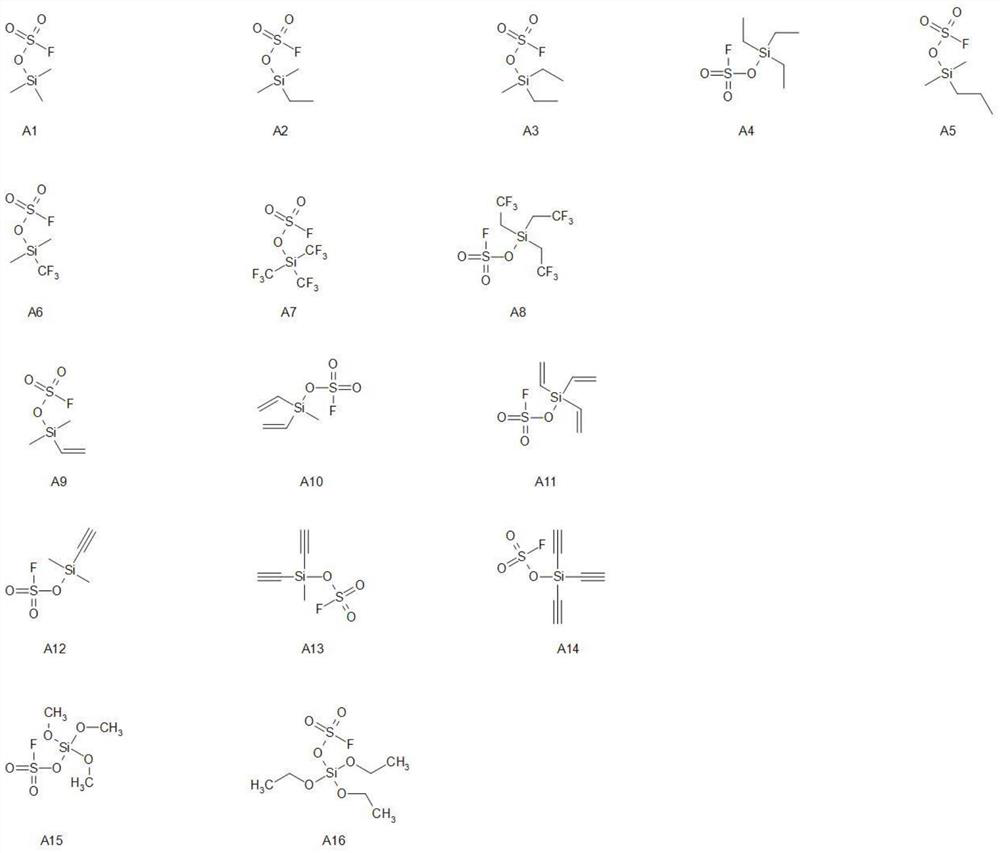

Method used

Image

Examples

preparation example Construction

[0052] Preparation of lithium-ion batteries

[0053] Preparation of positive electrode sheet

[0054] The positive electrode active material lithium nickel cobalt manganese oxide (LiNi 0.7 mn 0.2 co 0.1 ), the binder polyvinylidene fluoride (PVDF), and the conductive agent acetylene black Super-P were mixed according to the mass ratio of 96:2:2, N-methylpyrrolidone was added, and stirred in a vacuum mixer until stable and uniform to obtain the positive electrode slurry . The positive electrode slurry was uniformly coated on an aluminum foil with a thickness of 12um, and the coated aluminum foil was dried in a blast oven at 120°C, and then cold pressed and cut to obtain positive electrode sheets.

[0055] Negative sheet preparation

[0056] Negative electrode active material artificial graphite, binder styrene-butadiene rubber (SBR), thickener sodium carboxymethylcellulose (CMC), conductive agent acetylene black Super-P are mixed according to mass ratio 97:1:1:, add to Io...

Embodiment 1

[0072] Example 1 and Example 2 compared and evaluated the effect of cyclophosphazene additives shared with A1 and B1 additives. In this scheme, the combined use of A1 and B1 can achieve a better improvement effect. In this case, cyclophosphazene There is no synergistic improvement effect in the above, where C12 is the C2 cyclophosphazene compound in the Chinese patent ZL201611244549.0. In fact, the inventor has also done a good job in the combination and use of other cyclophosphazene compounds involved in this patent. Further studies did not show a further synergistic improvement effect, that is, the combination of fluorosulfonate and fluorophosphate can obtain better results without the presence of cyclic phosphazene compound.

[0073] Compared with Example 1 and Example 3, the introduction of C8 can significantly improve the cycle performance, high-temperature storage capacity retention rate and volume expansion rate, but it will deteriorate the low-temperature DCR of the bat...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com