Welding rod for 07MnNiMoDR steel spherical tank and preparation method of welding rod

A welding rod and spherical tank technology, applied in welding equipment, manufacturing tools, welding media, etc., can solve the problems of insufficiency, affecting the progress of the project, deterioration of low temperature impact toughness, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0034] In order to better understand the present invention, the technical solutions of the present invention will be further described below in conjunction with specific examples, but the present invention is not limited to these examples.

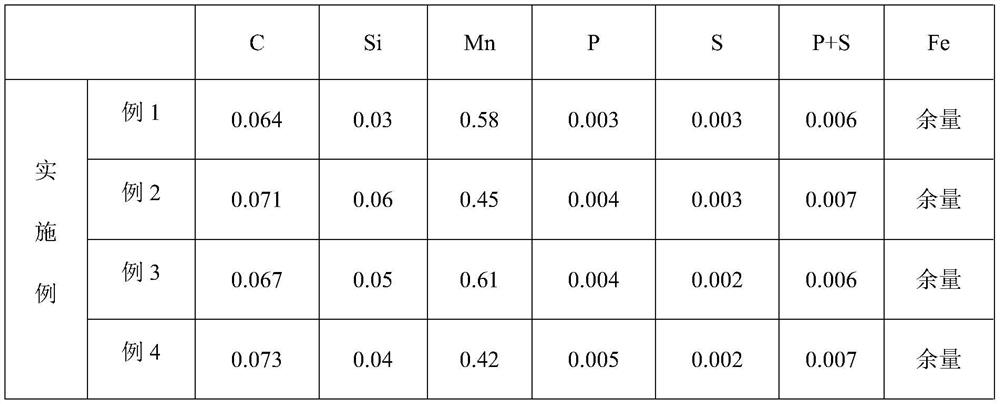

[0035] The present invention is made up of welding core and coating, and coating is coated on the outside of welding core, adopts high-quality ultra-low P, S carbon steel H08E welding core, and its welding core composition (weight percentage %) is as follows:

[0036] C: ≤0.08%;

[0037] Si: ≤0.10%;

[0038] Mn: 0.40~0.65%;

[0039] P: ≤0.005%;

[0040] S: ≤0.003%;

[0041] P+S: ≤0.008%;

[0042] Fe: balance;

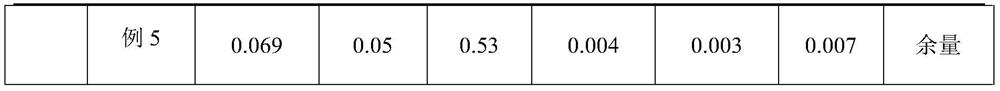

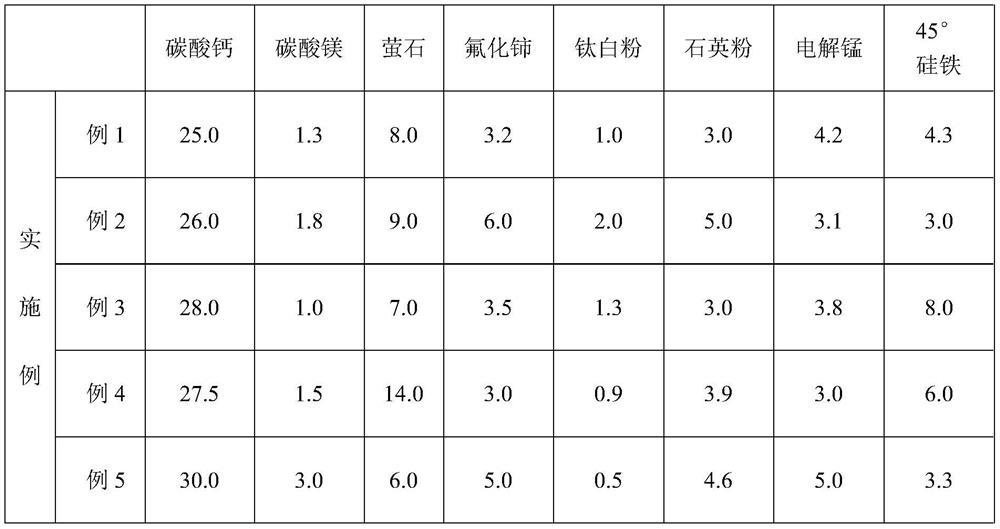

[0043] Based on the weight of the coating, the components and purity of the solder are as follows:

[0044] Calcium Carbonate (CaCO 3 ≥98%): 25-30%;

[0045] Magnesium Carbonate (MgCO 3 ≥99%): 1~3%;

[0046] Fluorite (CaF 2 ≥98%): 6~14%;

[0047] Cerium fluoride (CeF 2 ≥98.5%): 3~6%

[0048] Titanium dioxide (TiO 2 ≥9...

PUM

| Property | Measurement | Unit |

|---|---|---|

| tensile strength | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| modulus | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com