Silver particle surface passivation treatment method

A technology of passivation treatment and silver particles, which is applied in jewelry and other fields, and can solve the problem of non-existence of passivation on the surface of metal particles

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

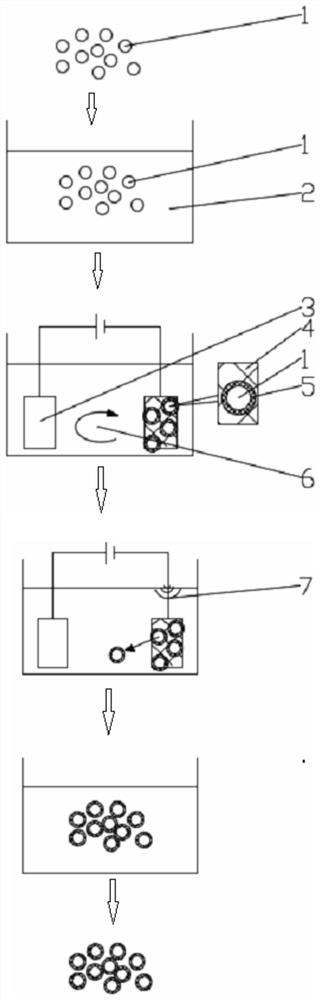

[0034] Embodiment 1 silver particle surface passivation treatment method A, technological process is as figure 1 As shown, wherein 1-silver particles, 2-solution containing passivation solution, 3-anode, 4-conductive porous mesh graphene electrode, 5-passivation layer, 6-mechanical stirring, 7-ultrasound of specific frequency.

[0035] (1) the silver particles of average size 100nm are dispersed in the solution containing passivation solution; the pH value of the solution containing passivation solution is 3, the solvent is ethanol, and the solute is H 2 o 2 、Cr 3+ 、Cr 6+ , SO 4 2- , Cl - , NO 3 - Mixtures of ions and alkali metal ions;

[0036] (2) mechanically stirring the solution, inserting graphite in the solution as an anode, inserting a conductive porous mesh graphene electrode with an aperture of 80 nm as a negative electrode, so that silver particles are attached to the conductive porous mesh graphene electrode;

[0037] (3) The solution is energized, and the...

Embodiment 2

[0039] Embodiment 2 silver particle surface passivation treatment method B, technological process such as figure 2 As shown, 1-silver particles, 2-solution containing passivation solution, 3-anode, 5-passivation layer, 6-mechanical stirring, 7-ultrasound with specific frequency, 8-water circulation made by pump, 9- Large aperture mesh graphene electrode, 10-medium aperture graphene mesh electrode, 11-small aperture mesh graphene electrode, 12-flip graphene electrode.

[0040](a) Disperse silver particles of 140nm, 110nm, and 80nm in a solution containing passivation solution, and put the solution in a closed container; the pH value of the solution containing passivation solution is 7, the solvent is methanol, and the solute is acrylic acid Resin, Cr 3+ 、Cr 6+ , SO 4 2- , Cl - , NO 3 - Mixtures of ions and alkali metal ions;

[0041] (b) The solution in the container is mechanically stirred, and an inert electrode is inserted into the solution from the side of the cont...

Embodiment 3

[0046] Other steps are the same as in Example 1, and the difference is that after the passivation process in step (3) finishes, the conductive porous mesh graphene electrode is taken out and placed in another solution, and hexadecane bromide is added in the other solution Trimethylammonium trimethylammonium (CTAB) and fatty acid salt small molecule surfactants reduce the surface energy of silver particles and promote the shedding of silver particles; apply ultrasonic vibration to make the passivated silver particles fall off; repeat the operation until all silver particles are passivated ; Then another solution is centrifugally dried to obtain passivated silver particles.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com