A kind of soi structure and manufacturing method, mems device and manufacturing method

A manufacturing method and device technology, applied in the field of SOI structure and manufacturing, and MEMS devices, can solve the problems of inability to effectively improve device reliability, poor insulation of isolation trenches, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0044] The technical solutions in the embodiments of the present invention will be apparent from the drawings in the embodiment of the present invention.

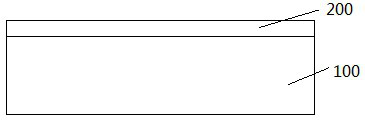

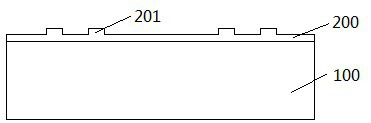

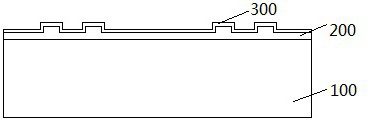

[0045] The following examples are deployed as an example of an SOI structure to achieve an isolation insulation application, first disclosed a SOI structure and a method of manufacturing the SOI structure, wherein the SOI structure is Image 6 As shown, the uppermost and upper, at least the first silicon layer 100, the insulating layer, and the second silicon layer 500 are included. The SOI structure (on the insulator) is often used in the manufacture of the MEMS device, mainly using the intermediate blankets to achieve insulation isolation between the electrodes. Unlike the existing SOI structure, a silica monolayer structure is used to form a blade layer. The insulating layer in the present embodiment is combined with a plurality of different material insulating materials, and the multilayers here are at least three layers, ie...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com