Supported photocatalyst and preparation method thereof

A photocatalyst, supported technology, applied in the field of supported photocatalyst and its preparation, can solve the problems of low coverage, easy to fall off, photocatalyst particles cannot cover the metal mesh in sufficient amount, etc., to increase the adhesion rate, not easy to fall off, The effect of enhancing the binding force

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

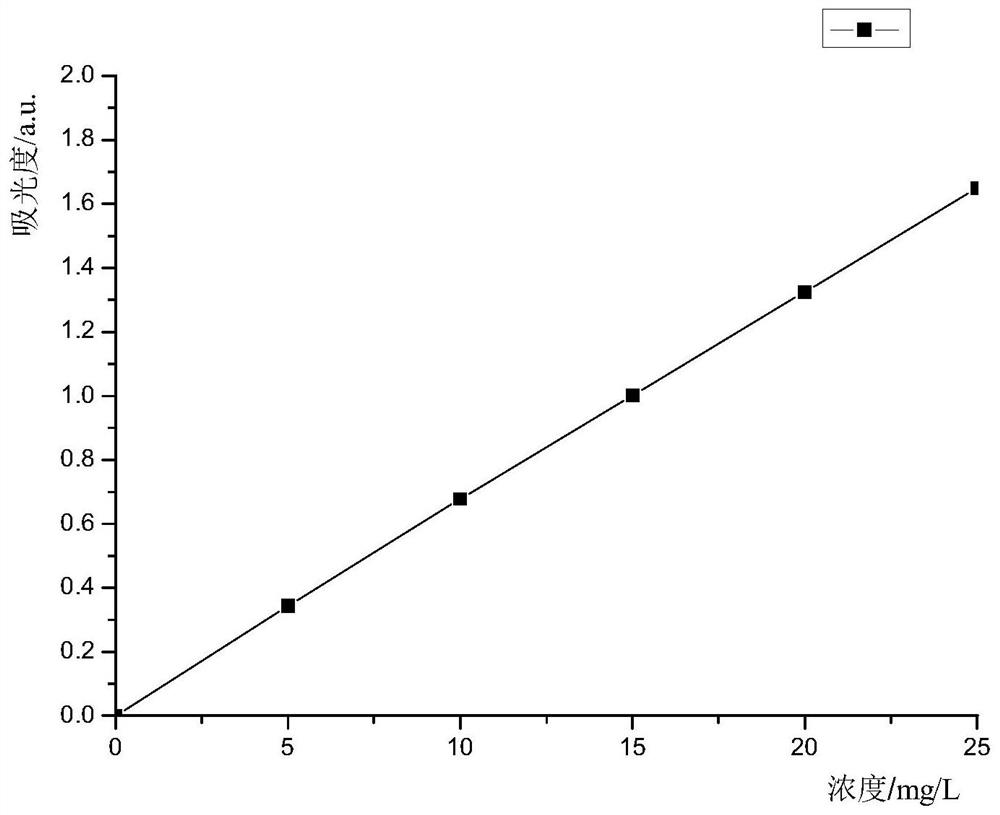

Image

Examples

preparation example Construction

[0034] The present invention also provides a preparation method of loaded photocatalyst, comprising the following process:

[0035] Step S1: providing a metal mesh. The material of the metal mesh can be iron, aluminum, iron alloy, aluminum alloy and the like.

[0036] Step S2: forming a metal oxide layer on the surface of the metal mesh.

[0037] In this step, in a specific embodiment, the metal mesh can be oxidized by the concentrated acid to form a dense metal oxide layer, and the formed metal oxide layer is not easy to fall off.

[0038] Step S3: Mix vinylpyrrolidone and waterproof organic polymer monomers, and copolymerize to form an organic compound.

[0039] Step S4: disperse the organic compound and photocatalyst particles in a solvent to obtain a coating liquid.

[0040] The solvent may be a polar solvent, such as water, ethanol or the like.

[0041] Step S5: forming a coating solution on the surface of the metal oxide layer, curing the coating solution to obtain a...

Embodiment 1

[0044] 1) Cut a metal mesh with an area of 5cm*5cm and place it in concentrated sulfuric acid with a concentration of 98%, so that the surface of the metal mesh is covered with an oxide layer of black iron oxide.

[0045] 2) Mix vinylpyrrolidone and methyl methacrylate with a molar ratio of 1:3, add potassium persulfide as an initiator with a mass content of 1.5%, heat to 80°C, stir while heating, react for 8 hours, and then, Cured under ultraviolet light, rinsed repeatedly with distilled water and then used for later use.

[0046] 3) Dissolve the organic compound prepared in step 2) in dichloroethane solvent, fully disperse, continue to add graphene, titanium dioxide, and curcumin to the solvent, and fully mix under 100r / min magnetic stirring to obtain coating liquid, in the coating liquid, the mass percentage of the organic compound to the total mass of the coating liquid is 5%, the mass percentage of the photocatalyst titanium dioxide to the total mass of the coating liquid...

Embodiment 2~5

[0049] The difference between Examples 2-5 and Example 1 lies in the proportion of the organic compound and the concentration of the organic compound in the coating liquid, and the rest are the same.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com