Process and device for producing sodium pyrosulfite by flue gas desulfurization method

A technology for sodium metabisulfite and a production device, applied in the field of preparation of sodium metabisulfite, can solve the problems of affecting the purity of sodium metabisulfite, high solubility and difficult to remove, and achieve the effects of improving yield, low cost, and inhibiting oxidation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0022] In order to make the object, technical solution and beneficial technical effects of the present invention clearer, the present invention will be further described in detail below in conjunction with the accompanying drawings and specific embodiments. It should be understood that the specific implementations described in this specification are only for explaining the present invention, not for limiting the present invention.

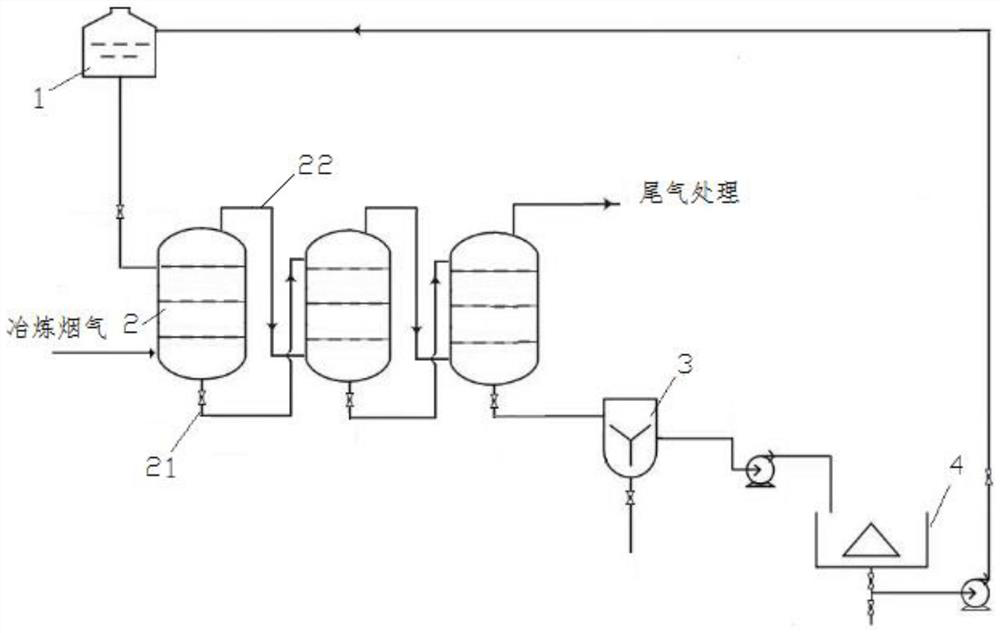

[0023] The invention provides a process for producing sodium pyrosulfate from flue gas desulfurization, the flow chart of which is as follows figure 1 shown.

[0024] Described processing step is as follows:

[0025] 1. Preparation of absorption solution: Na with a content of more than 85wt% 2 SO 3 The product is mixed with the mother liquor produced in the production process in a certain proportion to form NaHSO 3 、Na 2 SO 3 and Na 2 S 2 o 5 The mixed solution, control the Baume degree to be 54-56 degrees, and prepare it for later use;

...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com