Composite building material and intelligent temperature control system

A technology of composite building materials and phase change materials, which is applied in the field of composite building materials and intelligent temperature control systems, can solve the problems of low conversion utilization rate, high heating cost, low thermal efficiency, etc., and achieves clean heating, low cost, and improved economic benefits. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

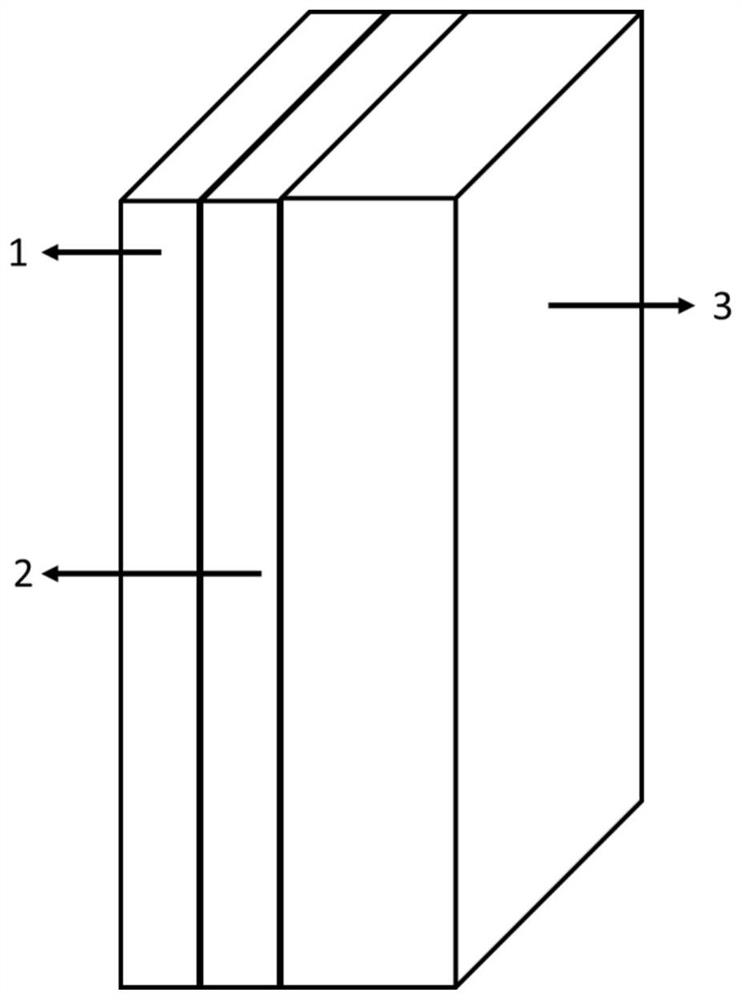

[0056] This embodiment provides a composite wall, such as figure 1 As shown, it includes an electric heating layer 1, an energy storage layer 2 and an insulation layer 3 that are laminated sequentially from indoor to outdoor.

[0057] Among them, in terms of mass percentage, the raw materials of the electric heating layer 1 include: 15% of spherical graphite tailings, 25% of cement, 55% of fine aggregate, and 5% of reinforcing materials (steel fibers with an aspect ratio of 30); among them, graphite waste The fine aggregate prepared from stone and graphite tailings (mass ratio 1:1) accounts for 20% of the total fine aggregate, and the rest is silica sand.

[0058] In terms of mass percentage, the raw materials of the energy storage layer 2 include: 10% cement, 70% fine aggregate, 5% graphite (spherical graphite tailings), 15% phase change material; fine aggregate prepared from graphite waste rock and graphite tailings It accounts for 20% of the total amount of fine aggregate,...

Embodiment 2

[0069] This embodiment provides a composite wall, which includes an electric heating layer, an energy storage layer and a thermal insulation layer that are laminated sequentially from indoor to outdoor.

[0070] Among them, in terms of mass percentage, the raw materials of the electric heating layer include: 13% of spherical graphite tailings, 20% of cement, 65% of fine aggregate, and 2% of reinforcing materials (steel fibers with an aspect ratio of 50); among them, graphite waste rock and The fine aggregate prepared from graphite tailings (mass ratio 1:1) accounts for 30% of the total fine aggregate, and the rest is silica sand.

[0071] In terms of mass percentage, the raw materials of the energy storage layer include: 40% cement, 45% fine aggregate, 5% graphite (spherical graphite tailings), 10% phase change material; fine aggregate prepared from graphite waste rock and graphite tailings accounted for 30% of the total amount of fine aggregate, and the rest of the fine aggre...

Embodiment 3

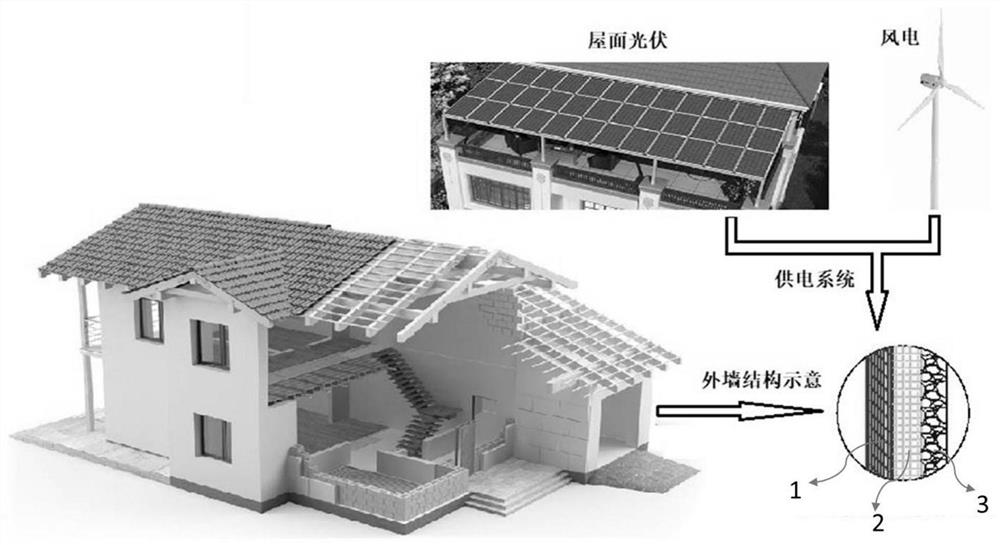

[0094] This embodiment provides an intelligent temperature control system, which includes a composite wall, a temperature sensor, a humidity sensor, a DC stabilized power supply and a PID controller. The temperature sensor and humidity sensor are installed on the indoor surface of the composite wall to monitor the temperature and humidity of the room and the wall; the DC stabilized power supply is connected to the electric heating layer in the composite wall to transmit the electric energy generated by photovoltaic power generation or small wind power The PID controller is connected to the temperature sensor, humidity sensor, and DC stabilized power supply respectively, and controls the DC stabilized voltage according to the indoor temperature and humidity collected by the temperature sensor and humidity sensor, combined with factors such as usage scenarios and ambient temperature differences. The situation of the piezoelectric power supply switch and the magnitude of the volta...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com