A kind of nto dissociation inhibitor and its application

An inhibitor and dissociation technology, which can be applied to a single substance as explosives, non-explosive/non-thermal components, and explosives, etc., can solve the problem of reducing the yield of NTO-based mixed explosives, the impact of animal and plant toxicity, and ecological and environmental hazards. and other problems, to achieve the effect of reducing preparation cost, mild experimental conditions, and reducing pollution

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

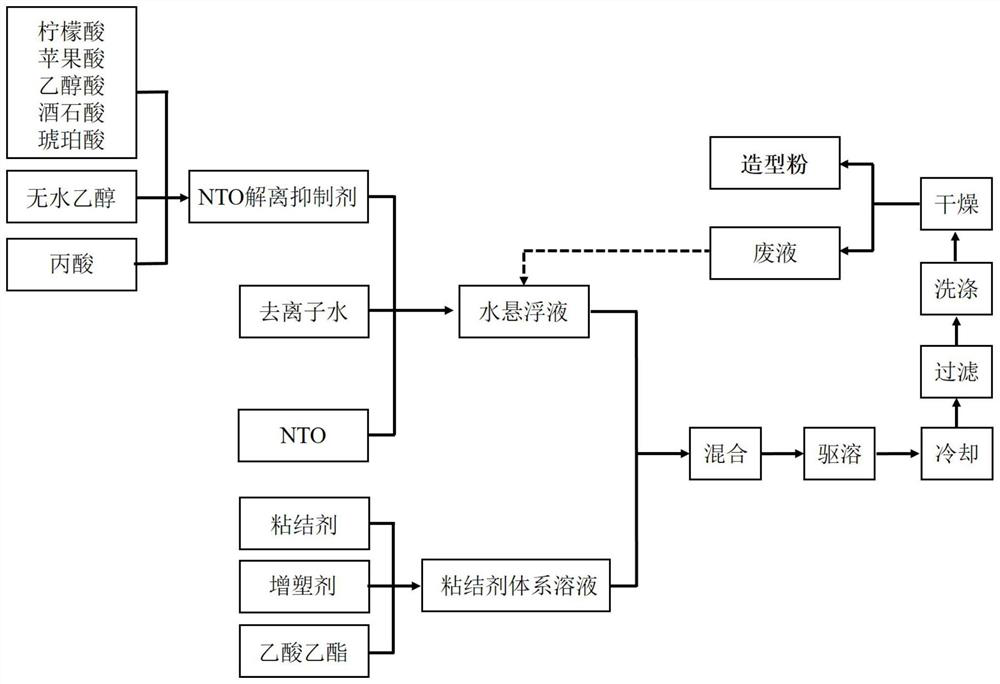

Method used

Image

Examples

Embodiment 1

[0032] At room temperature, add 0.5 g of citric acid to a 25 mL beaker, then add 10 mL of ethanol to dissolve the solid, then add 0.5 mL of propionic acid to the ethanol solution to prepare an NTO dissociation inhibitor.

[0033] Take 4g of Estane and 6g of nitroxyethyl nitramine into a conical flask, add 60mL of ethyl acetate, stir at room temperature, let it stand for a period of time to fully dissolve, and configure a binder system solution.

[0034] At room temperature, add the prepared NTO dissociation inhibitor into a 500mL beaker filled with 150mL deionized water, stir and mix well, then add 90g NTO, stir well to disperse evenly, and obtain an aqueous suspension of NTO. Subsequently, the water suspension of NTO was heated up to 50°C, and the prepared binder system solution was added dropwise to it at a stirring rate of 350r / min. After the dropwise addition was completed and kept for 20 minutes, the temperature of the system was raised to 60°C , to disperse the ethyl ace...

Embodiment 2

[0036] At room temperature, add 0.5 g of malic acid to a 25 mL beaker, then add 25 mL of ethanol to dissolve the solid, then add 1.0 mL of propionic acid to the ethanol solution to prepare an NTO dissociation inhibitor.

[0037] Take 2.4g of cellulose acetate butyrate and 3.6g of diethyl phthalate into a conical flask, add 50mL of ethyl acetate, stir at room temperature, let it dissolve for a period of time, and configure it as a binder system solution.

[0038]At room temperature, add the prepared NTO dissociation inhibitor into a 500mL beaker filled with 180mL deionized water, stir and mix thoroughly, then add 94g NTO, stir well to disperse evenly, and obtain an aqueous suspension of NTO. Subsequently, the water suspension of NTO was heated up to 50°C, and the prepared binder system solution was added dropwise to it at a stirring rate of 380r / min. After the addition was completed and kept for 20 minutes, the temperature of the system was raised to 60°C , to disperse the eth...

Embodiment 3

[0040] At room temperature, add 0.5 g of malic acid and 0.5 g of glycolic acid to a 25 mL beaker, then add 15 mL of ethanol to dissolve the solid, and then add 2.0 mL of propionic acid to the ethanol solution to prepare an NTO dissociation inhibitor.

[0041] Take 3.0g of fluororubber F2311 and 5.0g of diethyl phthalate into a conical flask, add 50mL of ethyl acetate, stir at room temperature, let it stand for a period of time to fully dissolve, and configure a binder system solution.

[0042] At room temperature, add the prepared NTO dissociation inhibitor into a 500mL beaker filled with 180mL deionized water, stir and mix well, then add 92g NTO, stir well to disperse evenly, and obtain an aqueous suspension of NTO. Subsequently, the water suspension of NTO was heated to 50°C, and the prepared binder system solution was added dropwise to it under the condition of a stirring rate of 450r / min. After the dropwise addition was completed and kept for 20 minutes, the temperature of ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com